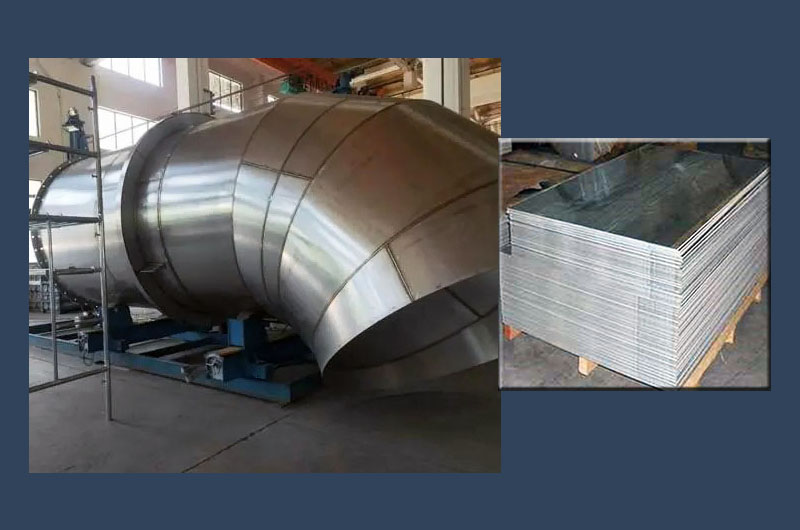

5083 5052 Marine Aluminum plate for ship chimney

A ship chimney, also called a funnel or chimney, is a vertical pipe or structure on a ship designed to vent gases produced by the ship's engines, boilers, and other machinery. The main function of the ship chimney is to discharge the exhaust gas, smoke and smoke inside the ship to the outside atmosphere.

Exhaust Ventilation: Chimneys help remove harmful gases, fumes, and fumes produced by a ship’s engines and machinery, preventing them from accumulating inside the ship and causing health hazards to passengers and crew.

Cooling: Chimneys also help cool exhaust gases before they are released into the atmosphere, lowering exhaust gas temperatures and minimizing environmental impact.

Why does ship chimney choose 5083 5052 aluminum?

5083 and 5052 marine grade aluminum plates are often used to manufacture ship chimneys due to their good strength, excellent welding performance and strong corrosion resistance.

- 1. Corrosion resistance: Both 5083 and 5052 aluminum alloys have excellent corrosion resistance, which is critical for ship chimneys exposed to harsh marine environments, including salt water and atmospheric humidity. This corrosion resistance helps extend the life of your chimney and reduces the need for maintenance.

- 2. Light weight: Aluminum alloys are lightweight compared to many other materials, making them ideal for use in ship construction where weight considerations are important. A lighter stack helps reduce the overall weight of the vessel, potentially improving fuel efficiency and performance.

- 3. Formability: 5083 and 5052 aluminum alloys are known for their excellent formability, allowing manufacturers to shape them into the complex geometries required for efficient chimney designs. This manufacturing flexibility helps produce chimneys that are both functional and beautiful.

- 4. High strength: Although aluminum is lightweight, it also has the characteristics of a high strength-to-weight ratio. This ensures that the chimney maintains its structural integrity even in harsh offshore conditions where it may be subject to wind, waves and other forces.

Ship Chimney of 5083 5052 Marine Aluminum plate Size

| Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) |

| 5083 |

O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34 H36, H38, H111, H112, H114, H 116, H321 |

3-50 | 20-2600 | 500-16000 |

| 5052 |

F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114 |

3-50 | 20-2650 | 500-16000 |

Marine aluminum products you may be interested in

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

5052 marine grade aluminium checkered tread plate sheet

5052 Marine Grade Aluminum Checkerboard combines superior corrosion resistance, enhanced traction, lightweight construction and versatility, making it ideal for a variety of marine applications where durability and safety are critical.

-

5052 O H112 Marine Grade Aluminum Bar

5052 O H112 Marine Grade Aluminum Rod is a rod made from 5052 aluminum alloy that is fully annealed to improve workability and tempered to provide strength and resistance suitable for marine applications.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

Marine Grade Aluminum Square Bar 5052 5A02

Marine-grade aluminum square bars 5052 and 5A02 are two commonly used aluminum alloy materials in marine and corrosive environments, known for their excellent corrosion resistance and mechanical properties.

-

5052 O H112 Marine Grade Aluminum Hexagon Bar

The 5052 O H112 aluminum alloy hexagonal bar has excellent corrosion resistance, making it suitable for the manufacture of ship components.

-

5052 O H112 Marine Grade Aluminum Round Bars

5052 aluminum round bars have excellent formability and durability, making them widely used in the manufacturing of ship components.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.

Ship Chimney of 5083 5052 Marine Aluminum plate Mechanical Properties

| Alloy | 5052 | 5083 | |

| Rp0.2(MPa) | Yield strength | ≥65 | ≥110 |

| Elastic Modulus | 69.3-70.7 | 70 | |

Ship Chimney of 5083 5052 Marine Aluminum plate Chemical Composition

| Alloy | 5083 | 5052 |

| Si | ≦0.4 | ≦0.25 |

| Fe | ≦0.4 | ≦0.4 |

| Cu | ≦0.1 | ≦0.1 |

| Mn | 0.40-1.00 | ≦0.1 |

| Mg | 4.00-4.90 | 2.2-2.8 |

| Cr | 0.05-0.25 | 0.15-0.35 |

| Zn | ≦0.25 | ≦0.1 |

| Ti | ≦0.15 | - |

| Zr | - | - |

| Unit | Wt% | |

Ship Chimney of 5083 5052 Marine Aluminum plate Corrosion Resistance

One of the most significant advantages of 5083 and 5052 marine aluminum alloys is their excellent corrosion resistance, especially in marine environments. The presence of magnesium and chromium gives the alloy self-healing properties, forming a protective oxide layer that prevents further corrosion. In addition, manganese helps refine grains and enhance the alloy's resistance to stress corrosion cracking.

The corrosion resistance of alloys 5083 and 5052 is evident in their ability to withstand long-term exposure to seawater, salt spray and atmospheric humidity without significant degradation. This resistance minimizes maintenance requirements and extends the life of the ship's chimney, ensuring long-term performance and reliability.

Ship Chimney of 5083 5052 Marine Aluminum plate Manufacturing Process

1. Alloy casting and ingot production

5083 and 5052 marine aluminum alloys are typically produced by casting aluminum ingots using methods such as continuous casting or direct chill casting. These processes ensure uniform composition and microstructure, which are essential to achieve the required mechanical properties. The alloy is then homogenized to eliminate any segregation and refine the grain structure, further improving the alloy's mechanical properties.

2. Plate rolling and heat treatment

After the alloy is cast, the aluminum ingots are hot-rolled into sheets of various thicknesses suitable for ship chimney construction. Heat treatment techniques such as solution heat treatment and quenching are used to optimize the microstructure of the alloy to improve strength and formability. The controlled cooling process is essential to prevent deformation of the finished aluminum sheet and ensure dimensional stability.

3. Surface treatment and coating

In order to enhance corrosion resistance and aesthetics, 5083 and 5052 marine aluminum plates undergo surface treatment processes such as anodizing and chemical conversion coating. Anodizing involves electrolytic oxidation, which creates a thick protective oxide layer on the aluminum surface, while chemical conversion coating chemically changes the surface to improve adhesion and corrosion resistance. In addition, protective coatings such as epoxy paint and powder coating can be applied to further protect aluminum panels from environmental degradation.

5083 5052 Marine Aluminum plate for ship chimney applications

1. Structural components

5083 and 5052 marine aluminum plates are widely used to manufacture ship chimney structural parts, including shells, flanges and brackets. Their high strength-to-weight ratio and excellent formability make them ideal materials for constructing lightweight yet durable chimney assemblies, capable of withstanding dynamic loads and harsh conditions encountered at sea.

2. Corrosion protection system

The corrosion resistance of 5083 and 5052 marine aluminum alloys aids in the design of marine stack corrosion protection systems. By using these alloys, shipyards can minimize the risk of corrosion-induced failures and reduce the maintenance costs associated with stack maintenance and repairs. Appropriate design considerations, including surface treatments and coating systems, can further improve the longevity and performance of aluminum-based ship stacks in corrosive marine environments.

3. Thermal insulation and ventilation

In addition to structural integrity and corrosion resistance, ship chimneys must provide effective insulation and ventilation for onboard systems. Aluminum alloys, including 5083 and 5052, have excellent thermal conductivity and can effectively remove heat from exhaust gases and mechanical rooms. Integrated ventilation systems within ship chimneys ensure adequate airflow, promoting efficient operation of engines, boilers and HVAC systems, while minimizing the risk of overheating and maintaining optimal environmental conditions on board.

Popular searches for marine aluminum materials

- Marine grade aluminum plates

- Marine grade aluminum checker plate

- Marine grade aluminum bar

- Marine grade aluminum honeycomb plate

- Marine grade aluminum foam sheet plate

- Marine grade ribbed stiffener aluminum plate sheet

- Marine grade aluminum welding wire

- Marine grade aluminum pipe tube

- Marine Aluminum Profiles

- Aluminium Flanges

- Aluminum Tees

- Aluminum Elbow

- Aluminum Pipe Fitting Caps

- Aluminum Reducer

- Aluminum/steel clad plate

Tags: Marine Grade Aluminum 5052 Marine Grade Aluminum 5083 5 Series Marine Aluminum Aluminum for Shipbuilding Aluminum for Boat