Aluminum Boat Trim

Aluminum Boat Trim is an important part of the appearance and functionality of boats. It is often used for decoration, protection, and enhancing the structural performance of the hull. These trims not only offer an aesthetically pleasing appearance but also resist seawater corrosion, ensuring durability during prolonged use. Aluminum alloy, as the primary material for boat trims, features lightweight, corrosion resistance, and ease of processing. Common aluminum alloy grades include the 6063, 6061, 6082, 5000, and 5083 series.

Aluminum Boat Trim Alloy Types and Characteristics

6063 T4 Aluminum Alloy for Boat Trim

Strength: 6063 T4 aluminum alloy has medium strength, suitable for components with low strength requirements, such as boat trims, decorative strips, etc.

Mechanical Properties: It has good machinability, allowing for welding and other processing techniques, which facilitates production.

Corrosion Resistance: This alloy has excellent corrosion resistance, particularly suitable for long-term use in marine environments.

Application: Commonly used for manufacturing decorative strips, window frames, door frames, and other detailed parts of the hull.

6061 Aluminum Alloy for Boat Trim

Strength: The higher strength of 6061 aluminum alloy allows it to maintain good structural integrity when bearing heavier loads, often used for more load-bearing components.

Corrosion Resistance: While not as corrosion-resistant as the 5083 alloy, its corrosion resistance can be significantly enhanced through anodizing.

Application: Suitable for high-end boat trim parts, offering a sturdier and more luxurious appearance.

6082 Aluminum Alloy for Boat Trim

Strength: 6082 aluminum alloy has higher strength than 6063 and is widely used in applications requiring high mechanical performance.

Corrosion Resistance: It offers good corrosion resistance, making it suitable for use in saltwater environments.

Application: Used in boat trims, especially for parts that need to withstand high external forces.

5000 and 5083 Aluminum Alloys for Boat Trim

Strength: The 5000 series aluminum alloy has extremely high corrosion resistance but relatively lower strength. The 5083 series aluminum alloy strikes a good balance between strength and corrosion resistance.

Corrosion Resistance: The 5083 alloy performs exceptionally well in marine environments, suitable for boat parts exposed to seawater.

Application: The 5083 alloy is often used in structural components of the hull, while the 5000 series alloys are suitable for decorative boat trims.

Extruded aluminum boat trims often use the 6063 T4 alloy grade. This alloy has medium strength, good mechanical properties, and excellent corrosion resistance. It can be easily welded and fabricated if you have the right equipment.

Specifications of Aluminum Boat Trim

| Item Name | Aluminum Boat Trim |

| Material | 6000 Series Aluminum Alloy |

| Temper | T4, T5, T6 |

| Open Mould | 10-15 days |

| Dimension/Sizes | Customize |

| MOQ | 500KG each one |

| Quality Standard | GB/T 5237-2008, GB/T 6892-2015 |

| Production Time | 20-25 days |

| Payment | T/T, L/C, etc |

| Surface Finish | Mill-finish, Anodized, Powder-coated |

| Standard Packaging | PE shrink film, Non-woven Fabric, Craft paper, Carton, Or customized packing |

| Deep process | Drilling, CNC, milling , cutting , bending , tapping , welding , assembling , punching |

Aluminum Boat Trim Processing and Surface Treatment

Aluminum Boat Trim Processing

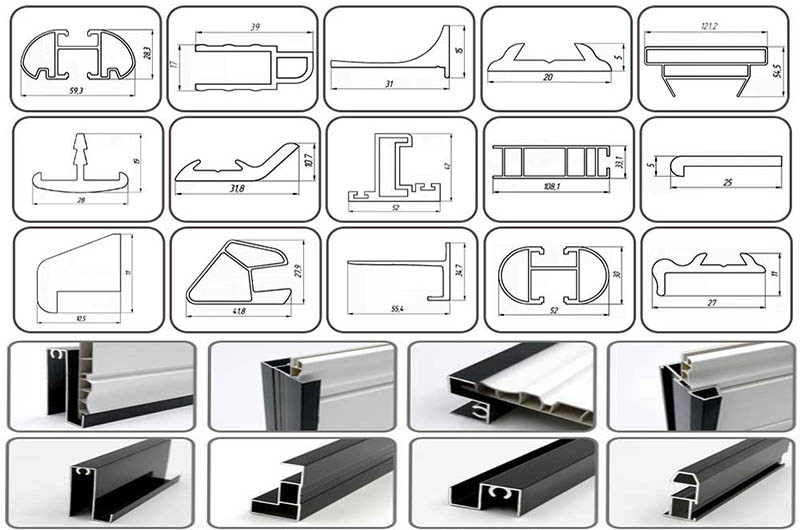

Extrusion: Aluminum alloy materials are typically processed using the extrusion method, which allows for the production of decorative components with complex shapes, such as window frames, railings, and various trim strips.

Aluminum Boat Trim Surface Treatment

Anodizing: Anodizing can enhance the corrosion resistance and aesthetics of the aluminum alloy surface. This process forms a hard oxide film on the aluminum surface, increasing its corrosion resistance.

Polishing: For boat trims that require a higher gloss, polishing is a common surface treatment process, providing the boat with a shiny finish and enhancing the visual effect.

Bright Dip: This treatment can give the aluminum alloy surface a higher degree of smoothness and is typically used to enhance the appearance of boat trims.

Powder Coating: Powder coating provides strong protection for the aluminum alloy surface, preventing corrosion and wear, while also offering a variety of color options to meet different boat design needs.

Why Choose Aluminum Alloy for Boat Trim?

Performance: Aluminum alloy boat trims have a lightweight feature, which helps reduce the overall weight of the boat. At the same time, the high strength and corrosion resistance of aluminum alloys ensure that they maintain structural stability and long service life even in harsh marine environments.

Aesthetic Effect: Surface treatments make aluminum alloy boat trims have diverse appearances, and the trim can be matched to the color of the hull to enhance the overall visual effect. Whether it is the silver shine after anodizing, the mirror-like effect after polishing, or the glossy appearance after bright dipping, these treatments all add a sense of luxury and high-class to the boat.

Common Applications of Aluminum Boat Trim

1. Hull Decorative Strips

Hull decorative strips are typically installed on the edges of the boat, on the gunwales, window frames, and door frames. They not only have decorative effects but also serve to protect the hull. By adding aluminum alloy decorative strips to the hull, the boat's appearance becomes more refined, and it can effectively prevent damage from water flow, seawater, and other external materials during navigation.

Advantages:

Aesthetics: Aluminum decorative strips, through fine processing and surface treatments (such as anodizing or polishing), enhance the luxurious feel of the boat and make the hull appear more modern.

Enhanced Structural Stability: The lightweight and strength of aluminum alloys allow decorative strips to enhance the structural stability of the hull, especially when the hull bears external forces. The strips can effectively disperse stress.

Corrosion Resistance: Aluminum alloys have excellent corrosion resistance, particularly in marine environments, which helps prevent rust and corrosion and extends the service life of the boat.

2. Boat Door and Window Frames

Aluminum alloy door and window frames are used for the hatches, windows, and doors of boats. They provide strong support while also giving the boat a more modern and elegant appearance. Boat door and window frames must withstand certain pressure, so high-strength aluminum alloys, such as the 6061 or 5083 series, are required.

Advantages:

Strength: Aluminum alloys have high strength and rigidity, which can effectively support the boat's doors and windows, especially in terms of resistance to external forces during navigation.

Aesthetic Appeal: Aluminum alloy frames can achieve a smooth surface through polishing or anodizing, enhancing the visual appeal of the boat.

Corrosion Resistance: Door and window frames are often exposed to seawater, and the corrosion resistance of aluminum alloys ensures their long service life even in harsh marine environments.

3. Railings and Guardrails

The railing and guardrail systems of a boat are critical safety components, especially on the deck, in passageways, and at the edges of yachts. Aluminum alloy railings and guardrails not only provide a physical barrier to prevent crew and passengers from falling overboard, but they also enhance the boat's appearance while providing safety.

Advantages:

Safety: Aluminum alloy railings and guardrails are designed to be strong and durable, able to withstand vibrations, impacts, and wave forces during navigation.

Lightweight: The lightweight property of aluminum alloys makes the railing and guardrail structure more convenient, reducing the load on the hull and improving the boat's overall performance.

Corrosion Resistance: The salt mist and moisture in marine environments can easily cause material corrosion. The corrosion resistance of aluminum alloys ensures that railings and guardrails maintain their appearance and structural integrity after long-term use.

4. Porthole Trims

Porthole trims are typically used for the frame and surrounding decoration of boat portholes. They not only enhance the appearance of the hull but also provide additional protection for the portholes. These trims are usually made from aluminum alloy and can be finely processed with surface treatments like anodizing or polishing to showcase a luxurious appearance.

Advantages:

Aesthetic Enhancement: Aluminum alloy trims can add a delicate touch to the portholes, making the entire boat appear more modern and luxurious.

Protection: These trims can protect the portholes from external impacts or wear during navigation, extending the lifespan of the portholes.

Corrosion Resistance: Porthole trims are exposed to marine environments, and the corrosion resistance of aluminum alloys ensures they maintain their performance and appearance after prolonged use.

5. Other Decorative Accessories

In addition to hull decorative strips, door and window frames, railings and guardrails, and porthole trims, aluminum alloys are also widely used in the manufacturing of other decorative accessories, such as window sills, hatch frames, hatch covers, and other auxiliary structural components. The main function of these accessories is to provide additional aesthetics and functionality to the boat while also enhancing its structural strength.

Advantages:

Versatility: Aluminum alloy materials can be processed and customized to meet the requirements of various decorative accessories.

Durability: These decorative accessories, when exposed to seawater and salt mist, benefit from the corrosion resistance of aluminum alloys, effectively preventing material degradation and ensuring a long service life.

Lightweight and Strength: The lightweight and strong characteristics of aluminum alloys enable these accessories to meet aesthetic needs while enhancing the boat's structural integrity without adding extra weight.

Aluminum boat trims not only enhance the appearance of the boat but also provide essential structural support with their lightweight, strength, and corrosion resistance. Whether in hull decorative strips, door and window frames, railings and guardrails, or porthole trims and other accessories, the versatility and excellent performance of aluminum alloys make them an indispensable material in boat design. With appropriate surface treatments (such as anodizing, polishing, and powder coating), aluminum alloys can withstand harsh marine environments and provide a luxurious and high-end appearance for the boat.

Aluminum boat trims made from 6063 T4 and other series of aluminum alloys not only meet the aesthetic design needs of boats but also ensure their durability in marine environments. With different surface treatments, such as anodizing, polishing, and powder coating, aluminum alloy boat trims can achieve the best balance between visual effects and functional performance. Whether enhancing the aesthetic appeal or improving the hull's corrosion resistance, aluminum alloy boat trims are an essential element in modern boat design.

Available Aluminum Boat Trim Options

| Product | Size | Type |

| 3/4" x 3/8" Aluminum Rub Rail | 3/4" x 3/8" | Aluminum Rub Rail |

| 1" x 1/2" Aluminum Rub Rail | 1" x 1/2" | Aluminum Rub Rail |

| 1/16" X 1-1/2" Aluminum Flat Molding | 1/16" x 1-1/2" | Aluminum Flat Molding |

| 1/4" x 1" Aluminum Edge Molding | 1/4" x 1" | Aluminum Edge Molding |

| 3/4" x 1/4" Aluminum Rub Rail | 3/4" x 1/4" | Aluminum Rub Rail |

| 1" x 3/16" Aluminum Rub Rail | 1" x 3/16" | Aluminum Rub Rail |

| 1/4" X 9/16" Aluminum Edge Molding | 1/4" x 9/16" | Aluminum Edge Molding |

| 1/4" X 13/16" Aluminum Edge Molding | 1/4" x 13/16" | Aluminum Edge Molding |

| 3/4" X 1-1/8" Aluminum T-Hatch Trim | 3/4" x 1-1/8" | Aluminum T-Hatch Trim |

| 9/16" x 13/16" Aluminum Transom Trim | 9/16" x 13/16" | Aluminum Transom Trim |

| 5/8" X 3/4" Aluminum T-Hatch Trim | 5/8" x 3/4" | Aluminum T-Hatch Trim |

| 3/4" X 3/4" X 1/16" Aluminum Angle | 3/4" x 3/4" x 1/16" | Aluminum Angle |

| 1/2" X 1" X 1/16" Aluminum Angle | 1/2" x 1" x 1/16" | Aluminum Angle |

| 1" X 1" X 1/16" Aluminum Angle | 1" x 1" x 1/16" | Aluminum Angle |

| 3/4" X 1-1/4" Aluminum Angle | 3/4" x 1-1/4" | Aluminum Angle |

| 1/2" X 3/16" Aluminum Half Oval Molding | 1/2" x 3/16" | Aluminum Half Oval Molding |

| 1" X 3/16" Aluminum Half Oval Molding | 1" x 3/16" | Aluminum Half Oval Molding |

| 3/4" x 5/8" Aluminum Drip Molding | 3/4" x 5/8" | Aluminum Drip Molding |

Popular searches for marine aluminum materials

- Marine grade aluminum plates

- Marine grade aluminum checker plate

- Marine grade aluminum bar

- Marine grade aluminum honeycomb plate

- Marine grade aluminum foam sheet plate

- Marine grade ribbed stiffener aluminum plate sheet

- Marine grade aluminum welding wire

- Marine grade aluminum pipe tube

- Marine Aluminum Profiles

- Aluminium Flanges

- Aluminum Tees

- Aluminum Elbow

- Aluminum Pipe Fitting Caps

- Aluminum Reducer

- Aluminum/steel clad plate

Tags: 6 Series Marine Aluminum Aluminum for Boat Aluminum for Shipbuilding Marine Aluminum 6082 Marine Aluminum 6061