5052 5083 5086 Marine Aluminum Plate for Ship Deck

The ship deck plays a vital role in the hull structure. It is not only a platform on the hull, but also bears the important functions of supporting the hull structure, separating cabins and mechanical equipment.

Generally speaking, ship decks are composed of aluminum plates and frames. Aluminum plates have excellent corrosion resistance and lightweight properties, which allow ships to reduce weight and increase speed and fuel efficiency when sailing at sea. At the same time, the strength of the aluminum plate can also meet the requirements for the use of the hull in complex maritime environments.

Ship decks play several key roles in ship operations:

- 1. Support structure: The ship deck provides a solid platform for the crew to walk and install equipment. It distributes the weight of cargo, machinery and personnel throughout the ship's structure.

- 2. Keep people safe: Properly constructed ship decks are critical to ensuring the safety of crew and passengers.

- 3. Function: Depending on the type of ship, the deck may include functions such as cargo handling equipment, anchor points for securing loads, and access to other parts of the ship.

In addition to selecting aluminum plates with strong corrosion resistance, the deck design can also be protected with anti-corrosion coatings, sealants and other materials to ensure long-term use of the deck in harsh marine environments.

The design and material selection of ship decks need to take into account corrosion resistance, water resistance, structural strength and sinking resistance to ensure safe and stable navigation of ships in complex marine environments.

Ship decks have high requirements for corrosion resistance, water resistance, anti-skid, and wear resistance. 5052, 5083, 5086 and 6061 marine grade aluminum sheets are often used.

5052 5083 5086 Marine Aluminum Plate for Ship Deck Advantages

- 1. Corrosion resistance: 5052 5083 5086 aluminum alloys all have strong corrosion resistance, especially in marine environments. Exposure to salt water will accelerate metal degradation. This corrosion resistance helps extend the life of ship decks, reduces maintenance costs and ensures long-term durability.

- 2. Lightweight: Compared with steel, 5052 5083 5086 aluminum alloy is significantly lighter, which helps improve the fuel efficiency and maneuverability of the ship. This weight reduction can also increase payload capacity, depending on the ship's design requirements.

- 3. Strength to weight ratio: Despite its lightweight nature, 5052 5083 5086 aluminum alloy still has an excellent strength to weight ratio, providing structural integrity and load-bearing capacity without adding unnecessary bulk to the ship design.

- 4. Formability: Aluminum alloys such as 5052, 5083 and 5086 are highly formable and can be manufactured into complex shapes and configurations with relative ease. The versatility of this design allows shipbuilders to optimize deck layouts for specific functional and operational requirements.

- 5. Low maintenance: Aluminum decks generally require less maintenance than steel decks due to their corrosion resistance and durability in marine environments. This means reduced downtime and operating costs over the entire life of the vessel.

The use of aluminum alloys on ship decks provides strength, corrosion resistance, lightweight construction and ease of maintenance, making it the first choice for many maritime applications.

Specification of Aluminium Deck Plate

| Alloy | 5052 | 5083 | 5086 |

| Temper | O, H14, H32, H34 | O, H32, H111, H 116, H321 | O/H111/H112/H116/H321 |

| Thickness(mm) | 3-50 | 3-50 | 3-50 |

| Width(mm) | 20-2650 | 20-2600 | ≦3600 |

| Length(mm) | 500-16000 | 500-16000 | 500-16000 |

Marine aluminum products you may be interested in

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

5052 O H112 Marine Grade Aluminum Bar

5052 O H112 Marine Grade Aluminum Rod is a rod made from 5052 aluminum alloy that is fully annealed to improve workability and tempered to provide strength and resistance suitable for marine applications.

-

5052 marine grade aluminium checkered tread plate sheet

5052 Marine Grade Aluminum Checkerboard combines superior corrosion resistance, enhanced traction, lightweight construction and versatility, making it ideal for a variety of marine applications where durability and safety are critical.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

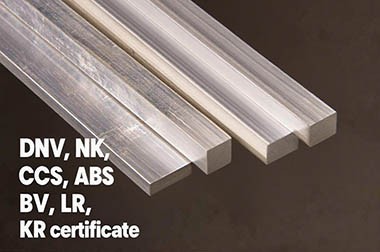

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5059 5086 Marine Grade Aluminum Bars

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

-

5086 marine grade aluminium checkered tread plate sheet

5086 marine grade aluminum checkered tread plate sheet has higher strength and corrosion resistance than 5052 and 5083 plates, making it ideal for many marine and marine applications.

-

Marine Grade Aluminum Square Bar 5052 5A02

Marine-grade aluminum square bars 5052 and 5A02 are two commonly used aluminum alloy materials in marine and corrosive environments, known for their excellent corrosion resistance and mechanical properties.

-

5052 O H112 Marine Grade Aluminum Hexagon Bar

The 5052 O H112 aluminum alloy hexagonal bar has excellent corrosion resistance, making it suitable for the manufacture of ship components.

-

5052 O H112 Marine Grade Aluminum Round Bars

5052 aluminum round bars have excellent formability and durability, making them widely used in the manufacturing of ship components.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.

-

As a direct manufacturer of 5086 Aluminum Sheet, we offer marine-grade aluminum plates that meet ASTM B209/EN 485 standards, featuring excellent seawater corrosion resistance and weldability.

-

As a professional aluminum plate manufacturer, we offer high-performance 5086 H116 aluminum alloy plates in a variety of specifications to meet the lightweight and industrial requirements of hulls.

-

As a leading manufacturer of aluminum alloys, we specialize in supplying 5086 H32 aluminum plate, ideal for harsh marine, industrial, and structural applications.

-

Our company specializes in the production of 5086 H111 medium-thick aluminum plates, with a finely polished surface and strong resistance to seawater corrosion. We offer customized cutting and welding services, and provide international certifications such as BV/DNV/ABS, with quick response to custom needs.

-

As a professional manufacturer of 5086 aluminum tubes, we offer seamless cold drawn aluminum tubes that comply with ASTM B210/B221 standards, with material strengthened by magnesium alloys, combining high strength and excellent seawater corrosion resistance.

-

5086 Aluminum Round Tubes and Pipes

As a professional aluminum alloy tube manufacturer, we offer 5086 aluminum alloy seamless round tubes, produced using high-precision cold drawing processes, conforming to international standards such as ASTM B210.

-

As a professional aluminum material manufacturer, we offer high-quality 5086 aluminum alloy square tubes, specifically designed for ships, marine engineering, and high-corrosion environments.

-

5086 Aluminum Drawn Seamless Pipe

As a leading manufacturer of precision aluminum products, we specialize in producing 5086 Aluminum Drawn Seamless Pipes designed for harsh environments.

-

5086 aluminum alloy round bars achieve high strength through cold mechanical processing, offering excellent seawater corrosion resistance and weldability. They are specifically designed for shipbuilding, marine engineering, and transportation equipment.

-

Professional production of 5086 aluminum flat bars, complete product specifications, direct sale from the manufacturer, favorable prices, strict quality control to ensure compliance with ASTM, EN, and other international standards.

-

As a professional aluminum alloy material manufacturer, we offer 5086 H111 aluminum alloy round bars, specially designed for harsh environments, suitable for shipbuilding, marine engineering, and industrial structural fields.

-

As a professional 5086 H32 pipe manufacturer, we provide high-performance, seawater corrosion-resistant customized pipe products, combining excellent strength and lightweight properties. Non-standard size processing is supported, and products are tested according to ISO certification and ASTM/EN standards.

-

As a leading supplier of 5086 aluminum alloy angles, we offer a full range of sizes in 5086-H111 structural angles, suitable for marine ladders, pressure vessels, and transportation equipment.

-

As a professional aluminum material manufacturer, we provide 5086 H111 aluminum alloy angles, combining high strength and excellent corrosion resistance, especially suitable for the marine, offshore engineering, and industrial structural fields.

-

5052 H32 aluminum sheet is known for its excellent fatigue strength, good weldability, and corrosion resistance, making it particularly suitable for marine environments and vehicle manufacturing.

-

As a professional 5052-H34 aluminum sheet manufacturer, we provide high-quality products that meet AMS 4017 and ASTM B209 standards, specifically designed for the marine, automotive, and aerospace industries.

-

5052 Aluminum Tube Marine Applicability: Resistant to seawater corrosion; ideal for use in marine components. Complies with ASTM/AMS standards and is suitable for the shipbuilding and aerospace industries.

-

5052 Aluminum Rectangular Tube

As a representative of the 5000 series aluminum-magnesium alloys, the 5052 aluminum rectangular tube, with its excellent corrosion resistance, moderate strength, and lightweight characteristics, has become a core material in shipbuilding, aerospace, and the automotive industry.

-

The 5052 aluminum square tube is made from 5052 aluminum alloy and is processed into a square tube. It belongs to the Al-Mg series rust-resistant aluminum alloy.

-

5052 aluminum round tubing is made from 5052 aluminum alloy, which is a round tubular material.

-

5052 H32 aluminum tube is a typical Al-Mg series rust-proof aluminum alloy tube, combining the process of work hardening and stabilization treatment.

-

5052 Drawn Aluminum Tubing is a specialized aluminum alloy product that is manufactured using a cold drawing process, in which the aluminum material is pulled through a die to achieve precise dimensions and a smooth surface.

-

5052-O aluminum tube is made from 5052 aluminum alloy and processed through annealing (O-temper) to form the tubing.

-

Seamless 5052 aluminum tubing is a high-performance material, famous for its outstanding corrosion resistance (especially in marine environments) and its suitability for various structural and fluid handling applications.

-

5052 Aluminum angle is a structural profile made from 5052 aluminum alloy, which is renowned for its excellent corrosion resistance, particularly in marine environments.

-

5052-H32 angle aluminum is an L-shaped structural profile made from 5052 aluminum alloy, which is processed in the H32 temper.

-

5052-H38 is a strain-hardened aluminum-magnesium alloy, known for its high strength, corrosion resistance, and versatility in industrial applications.

-

5052-H36 aluminum alloy is a high-strength, non-heat treatable material in the 5000 series, offering excellent corrosion resistance, especially in marine environments, while also providing good weldability and medium strength.

-

Specialized in producing 5083 aluminum bars, offering multiple tempers such as H112 and O, supporting custom machining with outer diameters ranging from Φ15mm to 450mm. Ample stock and fast delivery.

-

5083 aluminum round bar is a high-performance corrosion-resistant alloy primarily used in harsh environments, especially marine applications. This non-heat-treatable alloy achieves its mechanical properties through strain hardening. Common tempers include H111, H116, and H321.

-

We specialize in the production of 5083 aluminum square tubes, supporting customization of outer diameter (10–2500mm), wall thickness (0.4–100mm), and length (5–2000mm). Certified by ISO, SGS, BV, and other international standards to ensure stable and reliable mechanical properties.

-

Specializing in the production of 5083 H131 aluminum plates, we offer customized production with thicknesses from 0.2 to 350mm and widths from 30 to 2600mm. Global export supported, original factory warranty, and 30-day delivery.

-

5083-H32 aluminum plate plays a key role in shipbuilding due to its excellent performance. Whether used for structural components in large vessels or critical parts of high-performance speedboats, it delivers reliable performance and long-term durability.

-

5083 O aluminum is a special state aluminum material based on 5083 aluminum alloy, formed through an annealing process.

-

5083-H22 is an aluminum-magnesium alloy plate, belonging to the 5xxx series of non-heat-treatable aluminum alloys.

-

5083 H34 is a strain-hardened and stabilized aluminum alloy in the 5000 series, known for its high strength, excellent corrosion resistance, and good weldability.

-

5083 5383 Marine Grade Aluminium Hex Bar

The 5083 and 5383 aluminum hex bars produced by Haomei comply with multiple international and industry standards to ensure product quality and performance meet global application requirements.

-

5083 5383 O H112 Marine Aluminum Square Bar

Haomei Aluminum is capable of producing marine-grade 5083 and 5383 aluminum square bars in O and H112 tempers, certified by major international classification societies including DNV, NK, CCS, ABS, BV, LR, and KR.

Marine Aluminum Plate for Ship Deck Type

The main alloys of Marine Aluminum Plate for Ship Deck are 5052, 5083, and 5086.

5052 Marine Aluminum Plate for Ship Deck

- Alloy composition: 5052 aluminum alloy is mainly composed of aluminum, magnesium and trace amounts of chromium and manganese.

- characteristic:

- Excellent corrosion resistance: Due to the presence of magnesium, 5052 has excellent corrosion resistance in marine environments, making it ideal for ship decks exposed to salt water.

- Moderate Strength: While not as strong as some other aluminum alloys, 5052 still provides sufficient strength for marine deck applications, especially when paired with proper structural design.

- Formability: 5052 has excellent formability, enabling complex molding and manufacturing processes required for ship deck components.

- Weldability: The alloy is easily weldable, aiding assembly and repairs during ship construction and maintenance.

5083 Marine Aluminum Plate for Ship Deck

- Alloy composition: The main components of 5083 aluminum alloy are aluminum, magnesium, and small amounts of manganese, chromium, and zinc.

- characteristic:

- High Corrosion Resistance: Similar to 5052, 5083 has excellent corrosion resistance, especially in harsh marine environments, making it ideal for ship decks.

- Enhanced Strength: 5083 has higher strength compared to 5052, making it suitable for applications requiring greater structural integrity and load-bearing capacity.

- Weldability: Despite its increased strength, 5083 remains highly weldable, allowing for efficient fabrication and repair processes in the shipbuilding industry.

5086 Marine Aluminum Plate for Ship Deck

- Alloy composition: 5086 aluminum alloy contains aluminum, magnesium, manganese and trace amounts of chromium and zinc.

- characteristic:

- Excellent Corrosion Resistance: 5086 has excellent corrosion resistance, especially in salt water environments, making it ideal for marine applications.

- High strength: 5086 has the highest strength of the three alloys, making it ideal for demanding ship deck structures that are subject to heavy loads and dynamic forces.

- Weldability: Despite its increased strength, 5086 retains good weldability, ensuring ease of fabrication and repair in shipbuilding operations.

5052, 5083 and 5086 marine aluminum panels are widely used in the construction of ship decks, making them the primary structural material due to their durability, corrosion resistance and lightweight properties.

These alloys are used in a variety of deck components, including deck plating, bulkheads, hatch covers and superstructures, helping to improve the overall integrity and performance of the ship.

Their ability to withstand long-term exposure to harsh marine conditions, including salt water, humidity and UV radiation, ensures the long-term reliability and operational efficiency of ship decks.

In short, 5052, 5083 and 5086 marine aluminum plates have become indispensable materials in shipbuilding and maritime engineering due to their excellent corrosion resistance, strength, formability and weldability. These alloys play a key role in ensuring the structural integrity, durability and performance of ship decks, offshore platforms and marine equipment.

Popular searches for marine aluminum materials

- Marine grade aluminum plates

- Marine grade aluminum checker plate

- Marine grade aluminum bar

- Marine grade aluminum honeycomb plate

- Marine grade aluminum foam sheet plate

- Marine grade ribbed stiffener aluminum plate sheet

- Marine grade aluminum welding wire

- Marine grade aluminum pipe tube

- Marine Aluminum Profiles

- Aluminium Flanges

- Aluminum Tees

- Aluminum Elbow

- Aluminum Pipe Fitting Caps

- Aluminum Reducer

- Aluminum/steel clad plate

You might be interested in: Marine Grade Aluminum 5083 Marine Grade Aluminum 5052 Marine Aluminum 5086 5 Series Marine Aluminum Aluminum for Shipbuilding Aluminum for Boat 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5052 aluminum 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5052 aluminum sheet 5052 h32 5052 h34 5052 h32 aluminum 5052 aluminum plate 5052 0 aluminum sheet al5052 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum