5000 and 6000 Series Marine Aluminum for Building Cruise Vessels

Last Updated :

Aluminum alloy, as an advanced material for ship and marine engineering structural parts, has been widely used in the field of ship manufacturing.

Due to its excellent mechanical properties, corrosion resistance, fast sailing speed, long service life, high load-bearing capacity and low maintenance costs, aluminum alloy has become an important choice in the field of ship Cruise Vessels manufacturing, bringing great benefits to the ship transportation industry. Higher efficiency and better economic benefits.

Advantages of 5000 and 6000 Series Marine Aluminum for Building Cruise Ships

- 1. Excellent mechanical properties: Aluminum alloy has high specific strength and strength-to-weight ratio, which allows aluminum alloy cruise ships to have lighter weight and higher strength. This means the hull can be stronger while reducing its own weight, increasing the vessel's speed and fuel efficiency.

- 2. Corrosion resistance: Seawater contains a large amount of salt and humidity, which will cause serious corrosion problems to the metal structure of the ship. Aluminum alloy has good corrosion resistance and can effectively resist seawater corrosion, extending the service life of the cruise ship.

- 3. Fast sailing speed: Because the structure of aluminum alloy cruise ships is lighter and stronger, the ship can sail faster. This not only improves the transportation efficiency of the ship, but also improves the sailing experience of passengers.

- 4. Long service life: The corrosion resistance and high strength of aluminum alloy make aluminum alloy cruise ships have a longer service life. Compared with traditional steel structures, aluminum alloys can better resist seawater erosion, reducing ship maintenance and repair costs.

- 5. High load-bearing capacity: Although aluminum alloy is lighter than steel, its strength is considerable, which means that aluminum alloy cruise ships can carry larger loads, including more passengers and cargo, thus improving the economic benefits of the ship.

- 6. Low maintenance costs: Because aluminum alloys have good corrosion resistance and high strength, aluminum alloy cruise ships require relatively low maintenance costs during use. This reduces the overall cost of operating the vessel, making it more competitive.

5000 Series Marine Aluminum for Building Cruise Ships

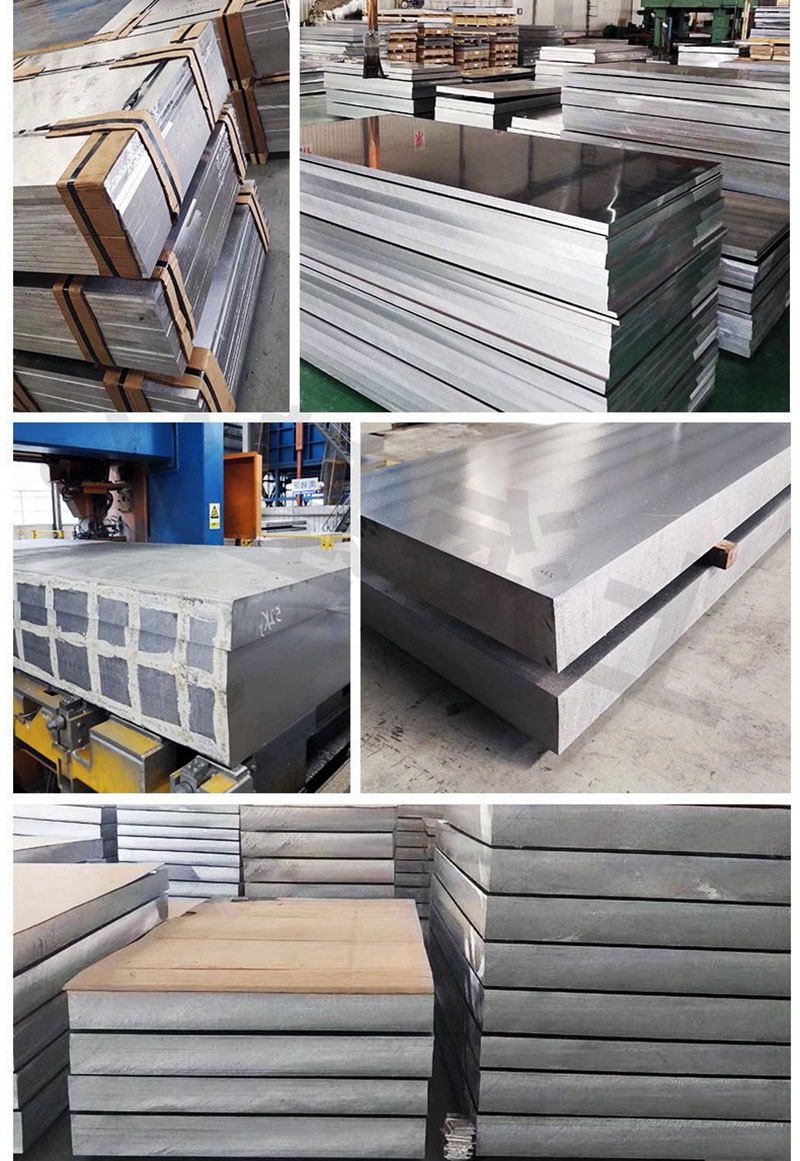

Non-heat treatable 5000 series aluminum alloys: such as 5052 and 5083 aluminum alloys, which have excellent corrosion resistance, especially for corrosive media such as seawater. These alloys have good weldability and formability, making them widely used in the shipbuilding industry. 5052 aluminum alloy is commonly used for the outer shell and structural components of cruise ship hulls, while 5083 aluminum alloy is commonly used for bottom plates and other components requiring high strength and corrosion resistance.

Features

- Good welding properties: 5 series aluminum alloys generally have excellent welding properties, which makes them easier to process and join during the manufacturing process.

- High strength: Although not as good as 6 series aluminum alloy, 5 series aluminum alloy also has considerable strength and is suitable for many application scenarios.

- Corrosion Resistance: Due to its natural corrosion resistance, Series 5 aluminum alloys are often used in applications that require long-term exposure to moisture.

Applications

Aluminum plate manufacturing: Mainly used to manufacture hulls and structural components of ships, yachts and other water vehicles.

Profile manufacturing: For example, 5050 aluminum alloy can be made into pipes and special-shaped profiles for use in construction, decoration and other fields.

Marine aluminum products you may be interested in

6000 Series Marine Aluminum for Building Cruise Ships

Heat-treatable 6000 series aluminum alloys: such as 6061 and 6082 aluminum alloys, which have high strength and good corrosion resistance and are suitable for use in marine environments. These alloys can be strengthened through heat treatment processes to increase their strength and hardness while maintaining good corrosion resistance. 6061 and 6082 aluminum alloys are commonly used in the shipbuilding industry for structural members, masts and other components that require high strength and lightweight materials.

Features

- Excellent deformation performance: 6 series aluminum alloy has excellent processing performance and is suitable for hot extrusion, cold extrusion and other processing methods.

- High strength: 6 series aluminum alloys generally have higher strength and hardness than 5 series aluminum alloys.

- Lightweight: The lightweight properties of aluminum alloys make 6-series aluminum alloys particularly popular in applications that require weight reduction.

Applications

Aluminum profile manufacturing: Mainly used to manufacture various profiles, including hot extruded profiles and die castings.

Aluminum plate manufacturing: often used to manufacture various structural parts, such as bridges, supporting structures of buildings, etc.

5 series aluminum alloys are usually used in the manufacture of aluminum plates and profiles, while 6 series aluminum alloys are more suitable for the manufacture of aluminum profiles and are also widely used in aluminum plates. The specific selection depends on the requirements of the application scenario, such as strength, processing performance and corrosion resistance.

In the construction of cruise ships, the most commonly used aluminum alloys include 5083, 5052, 6061 and 6082, etc. They all have good corrosion resistance and structural strength and are suitable for use in marine environments. These alloys can meet the requirements for material strength, corrosion resistance and lightweight during shipbuilding and are therefore widely used in yachts, cruise ships and various other types of shipbuilding.

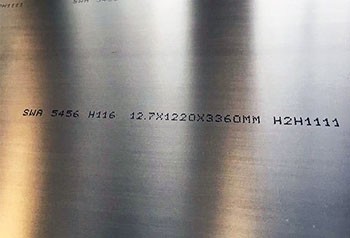

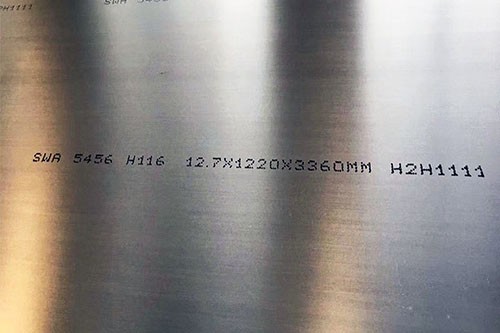

Tags: Marine Grade Aluminum 5083 Marine Grade Aluminum 5052 Marine Aluminum 5754 Marine Aluminum 5059 Marine Aluminum 5454 Marine Aluminum 5456 Marine Aluminum 5383 Marine Aluminum 5086 Marine Aluminum 6061 Marine Aluminum 6082 5 Series Marine Aluminum 6 Series Marine Aluminum