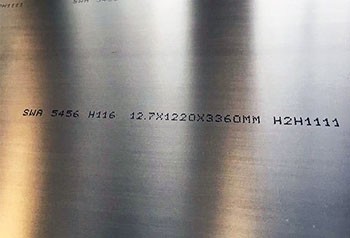

Marine grade aluminum 5052 5454 plate for shipbuilding

Last Updated :

Marine grade aluminum plate, commonly used aluminum alloy plate oil 5052, 5454, is often used in the shipbuilding industry due to its excellent corrosion resistance, high strength and light weight. These qualities make them ideal for offshore applications where durability and performance in harsh environments are critical.

The alloys of marine aluminum plates mainly include 5 series and 6 series, such as: 5052, 5083, 5086, 5454, 6061, 6063. The alloy states are: O, H34, H112, H116, H321, etc., which are generally used in ship shells, decks, etc.

Marine aluminum products you may be interested in

Marine grade aluminum 5454 plate offers significant advantages over marine grade aluminum 5052 plate, the main difference being its increased strength, which is approximately 20% greater than 5052. In addition to its exceptional strength, 5454 aluminum is also known for its excellent corrosion resistance, making it ideal for marine applications.

In comparison, the properties of 5454 aluminum are similar to 5154, another aluminum alloy commonly used in marine environments. Where 5454 shines, however, is its increased corrosion resistance, especially in harsh marine environments. This property makes it particularly suitable for critical applications such as ship hull structures, which are frequently exposed to salt water and other corrosive elements.

The corrosion-resistant properties of 5454 aluminum are critical to ensuring the longevity and durability of boat hulls as they are constantly exposed to seawater and environmental factors. By selecting 5454 aluminum for hull structure, shipbuilders can reduce the risk of corrosion-related issues and maintain structural integrity for the life of the vessel.

Marine-grade aluminum 5454 panels stand out for their impressive strength and unparalleled corrosion resistance, especially in demanding marine environments. Its superiority over 5052 aluminum, combined with its similarity to 5154 aluminum but greater corrosion resistance, makes it an excellent choice for critical marine applications such as ship hull structures.

Marine grade aluminum 5052 5454 plate for shipbuilding applications

Marine grade aluminum 5052 plate for shipbuilding

Known for its good formability and weldability, 5052 alloy also has excellent resistance to salt water corrosion, which is critical for long-term exposure to marine environments.

- Temper: For marine applications, aluminum alloy 5052 is typically used in the H32 temper condition. This temper provides a balance of strength and formability, making it suitable for fabrication processes while still offering good mechanical properties for structural components.

- Specifications: Specifications for marine grade aluminum 5052 plates often adhere to industry standards such as ASTM B209 or MIL-DTL-46177.

Marine grade aluminum plate 5052 is mainly used in superstructures, auxiliary components, and hulls.

- Superstructures: Aluminum 5052 is favored for constructing superstructures on ships due to its lightweight nature and high corrosion resistance. Superstructures, typically located above the main deck, house navigation equipment, accommodation areas, and other essential facilities for crew members.

- Auxiliary Components: Components such as handrails, ladders, and staircases are often made from 5052 alloy due to its good formability and weldability. These auxiliary structures contribute to the functionality and safety of the vessel.

- Hulls: While not as common as steel hulls, aluminum 5052 is used in constructing smaller vessels' hulls. Its corrosion resistance and lightweight properties make it suitable for boats and yachts where weight reduction and durability are essential.

Marine grade aluminum 5454 plate for shipbuilding

Alloy 5454 has similar properties to 5052 but is stronger. It has excellent corrosion resistance, especially in salt water environments, making it ideal for marine structural applications.

- Temper: Similar to alloy 5052, aluminum alloy 5454 is commonly used in the H32 temper condition for marine applications. This temper provides a balance of strength and formability, making it suitable for various fabrication processes while maintaining excellent corrosion resistance.

- Specifications: Specifications for marine grade aluminum 5454 plates typically conform to standards such as ASTM B928 or MIL-DTL-46127.

Marine grade aluminum 5454 plate is used for ship hull structures, pressure vessels, pipes, etc.

- Ship Hull Structures: The hull is the primary structural component of a vessel, providing buoyancy and structural integrity. Aluminum 5454 plates are used in ship hull construction due to their superior corrosion resistance and strength-to-weight ratio.

- Pressure Vessels: In maritime applications, pressure vessels are used for storing or transporting liquids or gases under pressure. Aluminum 5454 is preferred for pressure vessel construction due to its corrosion resistance and ability to withstand harsh marine conditions.

- Pipes and Piping Systems: Aluminum 5454 pipes are utilized in marine piping systems for conveying fluids and gases on ships. The alloy's corrosion resistance and durability make it suitable for withstanding the corrosive effects of seawater.

Marine grade aluminum 5052 5454 plate for shipbuilding performance

| Property | Alloy 5052 | Alloy 5454 |

| Tensile Strength | 210 - 230 MPa | 245 - 295 MPa |

| Yield Strength | 140 - 180 MPa | 95 - 145 MPa |

| Elongation at Break | 12% - 16% | 10% - 12% |

| Hardness (Brinell) | 60 HB | 68 HB |

Marine grade aluminum 5052 5454 plate for shipbuilding chemical composition

| Element | Alloy 5052 | Alloy 5454 |

| Magnesium | 2.2% - 2.8% | 2.4% - 3.0% |

| Chromium | 0.15% - 0.35% | 0.05% - 0.20% |

| Iron | 0.0% - 0.45% | 0.0% - 0.25% |

| Silicon | 0.0% - 0.25% | 0.0% - 0.25% |

| Copper | 0.1% max | 0.10% max |

| Manganese | 0.1% max | 0.50% - 1.0% |

| Zinc | 0.1% max | 0.25% max |

| Titanium | 0.1% max | 0.20% max |

| Aluminum | Balance | Balance |

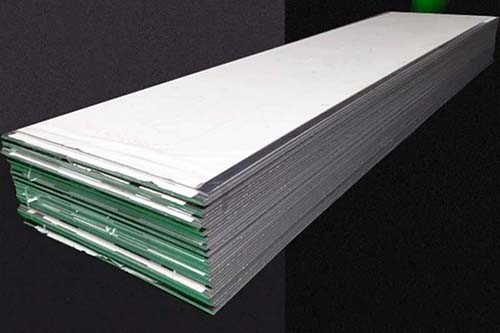

Marine Grade Aluminum Materials for Ship Structure

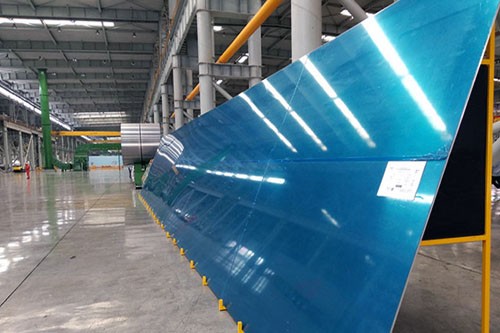

Haomei Aluminum is a manufacturer dedicated to the production and sales of ship plates, marine aluminum welding wires, marine aluminum profiles and other marine-related products, with guaranteed quality and competitive prices.

Factors to Consider When Choosing Marine Grade Aluminum Plate

There are several key factors to consider when selecting marine grade aluminum plate for boat building. First, the specific requirements of the vessel must be assessed. Factors such as size, intended use and operating conditions influence the choice of aluminum alloy and sheet thickness.

- 1. The intended application of the aluminum component must be carefully evaluated. Different parts of the ship, such as superstructure, hull, auxiliary parts, etc., have different requirements in terms of strength, corrosion resistance and formability. Matching the correct alloy and temper condition for each application ensures optimal performance and service life.

- 2. Compliance with regulatory standards is critical to the shipbuilding industry. Various industry and government regulations regulate the materials and manufacturing processes used in marine construction to ensure safety, reliability and environmental sustainability. Compliance with these standards is not only a legal requirement but is also critical to maintaining a ship's seaworthiness.

- 3. The manufacturing technology used plays an important role in the performance of marine grade aluminum components. Processes such as extrusion, rolling and welding must be performed precisely to maintain material integrity and mechanical properties. In addition, surface treatments such as anodizing or coating may be required to enhance corrosion resistance and protect against harsh marine environments.

Selecting the appropriate marine-grade aluminum panel requires a thorough evaluation of vessel requirements, application details, regulatory compliance and meticulous manufacturing processes. By taking these factors into consideration, shipbuilders can ensure optimal performance and longevity of aluminum components in the marine environment.

Tags: Marine Grade Aluminum 5052 Marine Aluminum 5454 5 Series Marine Aluminum Aluminum for Shipbuilding