5052 and 5083 aluminum characteristics in saltwater

Last Updated :

Aluminum alloy 5083 exhibits higher corrosion resistance in saltwater, making it particularly suitable for marine applications. Aluminum alloy 5052 has a relatively low corrosion rate in saltwater but is not as durable as 5083.

Both 5052 and 5083 aluminum alloys are commonly used types of aluminum alloys, widely applied in marine and other corrosive environments. Their characteristics in saltwater show significant differences, mainly in corrosion resistance, strength, and weldability.

When choosing an aluminum alloy for saltwater environments, aluminum alloy 5083 is clearly the superior choice due to its higher corrosion resistance and strength. Although 5052 aluminum alloy is still effective in certain applications, its durability may not match that of 5083 in extreme marine conditions.

Below is a comparison table of the characteristics of 5052 and 5083 aluminum alloys in saltwater:

| Characteristics | 5052 Aluminum Alloy | 5083 Aluminum Alloy |

| Corrosion Resistance | Good, but not as durable as 5083 | Superior, suitable for extreme marine environments |

| Corrosion Rate | Relatively low, but may accelerate at high salt concentrations | Low, effectively resists pitting and crevice corrosion |

| Strength | High yield strength and tensile strength | High strength and toughness, especially performs well at low temperatures |

| Workability | Excellent formability and weldability | Good, suitable for high strength and high durability applications |

| Applications | Non-structural components, hull outer plates, fuel tanks, etc. | Ship structural frames, hulls, side plates, etc. |

Characteristics of 5052 Aluminum Alloy in Saltwater

Corrosion Resistance: 5052 aluminum alloy exhibits good corrosion resistance, especially in freshwater environments. However, its corrosion resistance is slightly inferior to that of 5083 aluminum alloy in saltwater.

In saltwater environments, 5052 aluminum alloy may experience some degree of corrosion, particularly under high-temperature or high-humidity conditions. The corrosion rate of 5052 is relatively low but can still be affected by saltwater, especially in high-temperature and high-salt concentration scenarios.

Strength and Workability: 5052 aluminum alloy has relatively high strength and excellent formability and weldability, making it suitable for applications that require processing and shaping. Its high yield strength and tensile strength allow it to be used in some medium-load marine environments.

Applications: 5052 is commonly used for non-structural components in shipbuilding, hull outer plates, and other parts that come into contact with seawater, such as fuel tanks and water tanks. However, coatings or other protective measures may be needed to enhance its corrosion resistance.

Characteristics of 5083 Aluminum Alloy in Saltwater

Corrosion Resistance: 5083 aluminum alloy exhibits superior corrosion resistance in saltwater, making it suitable for extreme marine environments. Its high magnesium content and other alloying elements allow it to effectively resist pitting and crevice corrosion caused by chlorides. This makes 5083 aluminum alloy an ideal choice for marine applications, such as ships, offshore platforms, and other marine structures. Its excellent corrosion resistance ensures good performance even after prolonged exposure to saltwater environments.

Strength and Toughness: In addition to its corrosion resistance, 5083 aluminum alloy possesses high strength and toughness, particularly under low-temperature conditions. This makes 5083 an ideal choice for high-strength and high-durability applications.

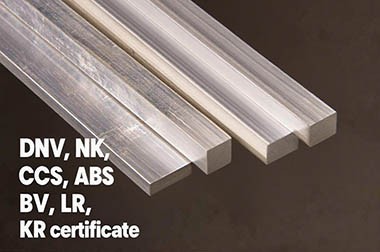

Applications: 5083 aluminum alloy is widely used in ships and marine structures, such as the structural frames, hulls, and side plates of vessels. It is also an ideal material for offshore platforms and cargo ships, capable of withstanding the corrosion from saltwater and extreme weather conditions.

When selecting an aluminum alloy for saltwater environments, 5083 aluminum alloy is clearly the superior choice due to its higher corrosion resistance and strength. While 5052 aluminum alloy remains effective in certain applications, its durability may not match that of 5083 in extreme marine conditions.

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5052 Marine Grade Aluminum 5083 5 Series Marine Aluminum 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5052 aluminum 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5052 aluminum sheet 5052 h32 5052 h34 5052 h32 aluminum 5052 aluminum plate 5052 0 aluminum sheet al5052 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum