5083 h111 marine aluminum plate performance characteristics

Last Updated :

The excellent performance characteristics of 5083 H111 aluminum plate make it an ideal material for shipbuilding and marine engineering, providing long-term reliable performance.

Haomei Aluminum's 5083 H111 aluminum plate has stable performance, utilizing strict quality and environmental management systems, and has passed certifications such as CCS, DNV, NK, CCS, ABS, BV, LR, and KR.

What is 5083 H111?

5083 H111 is a specific temper of an aluminum alloy, suitable for marine environments, with good corrosion resistance and moderate strength.

- 5083 refers to the specific grade of the aluminum alloy, which is a marine-grade aluminum alloy known for its excellent corrosion resistance and strength.

- H111 is one of the temper designations for aluminum alloys, indicating that the material has undergone light heat treatment to increase strength but has not been fully hardened.

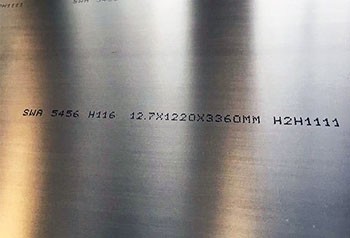

The specification of 5083 h116 marine grade aluminum plate sheet

| 5083 | Temper | Thickness |

| O, H111 | 3.00-50.00 | |

| H22, H32 | 3.00-6.00 | |

| H116, H321 | 3.00-50.00 | |

| H112 | 6.00-50.00 |

Features of 5083 H111 Marine Aluminum Plate

1. Corrosion Resistance

Excellent Corrosion Resistance: 5083 H111 aluminum alloy exhibits exceptional corrosion resistance in marine environments. Its high magnesium content allows it to effectively resist seawater corrosion, preventing oxidation and corrosion, thereby ensuring durability and structural stability during long-term use.

2. Strength and Hardness

High Strength: 5083 H111 aluminum alloy provides high strength, capable of withstanding significant loads and pressures. Its strength makes it suitable for structural components that need to endure various stresses in marine environments, such as hulls and frames.

Moderate Hardness: The H111 temper of aluminum alloy has undergone light cold working, resulting in moderate hardness. Compared to the H112 and H321 tempers, it slightly reduces the hardness of the material but still retains sufficient strength and toughness.

3. Weldability

Good Weldability: 5083 H111 aluminum alloy has good weldability, making it suitable for processing and assembly through various welding methods. This allows for complex welding processes in shipbuilding, ensuring the reliability of connected components.

4. Workability

Moderate Workability: Although the H111 temper of aluminum alloy has higher strength compared to other tempers, it still possesses moderate workability. It can be cut and formed through methods such as machining and stamping, meeting various design requirements.

Chemical composition of 5083 h116 marine grade aluminum plate sheet

| Element | Composition % |

| Al | REM |

| Si | ≤0.4 |

| Cu | ≤0.10 |

| Mg | 4.0-4.9 |

| Zn | ≤0.25 |

| Mn | 0.40-1.0 |

| Ti | ≤0.15 |

| Cr | 0.05-0.25 |

| Fe | ≤0.40 |

| Note: Single≤0.05; Total≤0.15 | |

Mechanical properties of 5083 h116 marine grade aluminum plate sheet

| Alloy | Temper | Thickness mm | Tensile Strength RmMPa | Specified non-proportional tensile strength Rp0.2 Mpa | Elongation% | |

| A50 mm | A | |||||

| 5083 | O | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 |

| H111 | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 | |

| H22, H32 | 3.00-6.00 | 305-380 | ≥215 | ≥8 | - | |

| H116 | 3.00-50.00 | ≥305 | ≥215 | ≥10 | ≥10 | |

| H321 | 3.00-50.00 | 305-385 | ≥215 | ≥12 | ≥10 | |

| H112 | 6.00-50.00 | ≥275 | ≥125 | ≥12 | ≥10 | |

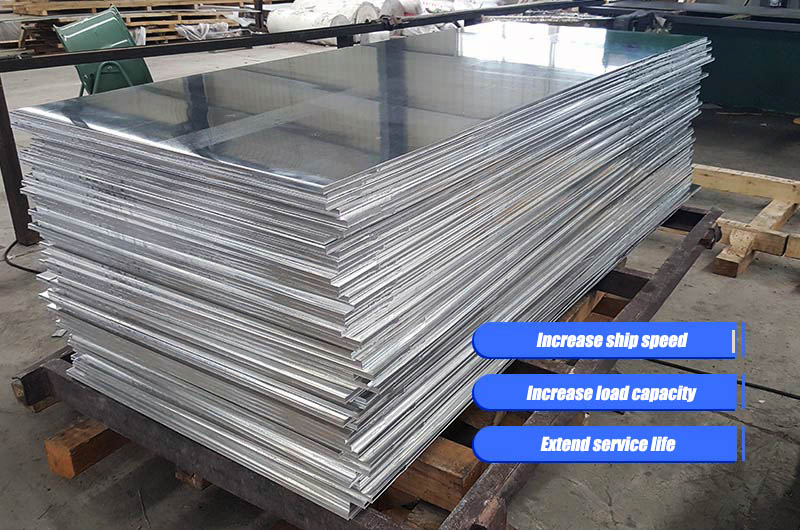

Applications of 5083 H116 Marine Grade Aluminum Plate

5083 H111 Aluminum Alloy due to its exceptional corrosion resistance and excellent mechanical properties, 5083 H111 aluminum alloy is widely used in fields requiring high corrosion resistance. Particularly in shipbuilding, 5083 H111 aluminum alloy is commonly used for hulls and outer panels, effectively resisting corrosion and erosion in marine environments. In addition, this alloy is often used in the manufacturing of oil tanks and other components that need to withstand corrosive environments for extended periods. Its outstanding performance ensures long service life and reliability in these applications.

5083 H111 Aluminum Plate for Hulls

5083 H111 aluminum alloy is extensively used in hull construction. Thanks to its extremely high corrosion resistance, this aluminum alloy can withstand the corrosive effects of saltwater, moisture, and other corrosive agents in marine environments, thereby extending the lifespan of the hull. Furthermore, the high strength characteristics of 5083 H111 aluminum alloy ensure the structural integrity and safety of the hull.

5083 H111 Aluminum Plate for Ship Outer Panels

In the manufacturing of ship outer panels, the use of 5083 H111 aluminum alloy provides excellent surface corrosion resistance. The outer panels are exposed to seawater and air, facing significant environmental challenges. 5083 H111 aluminum alloy effectively resists these challenges, maintaining the integrity and appearance of the outer panels.

5083 H111 Aluminum Plate for Oil Tanks

For oil tanks used to store various liquids, 5083 H111 aluminum alloy is an ideal material choice due to its outstanding corrosion resistance and chemical corrosion resistance. It can withstand contact with various chemicals inside the tank without easily corroding, ensuring the structural stability and long-term use of the tank.

Other High Corrosion Resistance Components

In addition to hulls, ship outer panels, and oil tanks, 5083 H111 aluminum alloy is widely used in other components requiring high corrosion resistance, such as marine platforms, pontoons, and some high-demand industrial equipment. Its excellent corrosion resistance and mechanical properties make it perform exceptionally well in these applications, capable of withstanding harsh environmental conditions.

What is the difference between 5083 H111 and H112?

The H112 temper offers higher performance, making it suitable for applications requiring greater strength and durability, while the H111 temper is more commonly used in situations where strength requirements are lower.

| Characteristics | 5083 H111 | 5083 H112 |

| Heat Treatment and Stress Relief | Simple annealing to remove processing stresses | Subjected to rigorous heat treatment and stress relief |

| Mechanical Properties | Relatively lower strength and hardness, with good machinability | Higher strength and hardness, with better mechanical performance |

| Applications | Suitable for components with lower strength requirements, such as hulls | Suitable for high-load applications, such as structural components |

| Performance Stability | Performance may vary slightly | More stable and consistent performance |

1. Heat Treatment and Stress Relief

H111: This temper typically refers to a simple annealing process primarily aimed at removing stresses induced during processing. H111 aluminum alloys are usually not heavily hardened, resulting in slightly lower mechanical properties compared to H112. However, H111 offers good machinability and sufficient strength.

H112: This temper generally indicates a more rigorous heat treatment and stress relief process. Compared to H111, H112 provides higher strength and better mechanical properties. H112 aluminum alloys undergo treatment after processing and forming to optimize their performance.

2. Mechanical Properties

H111: Mechanical properties are relatively lower and are used in applications with less demanding requirements. Its strength and hardness are lower, but it offers good ductility and formability.

H112: Due to its more stringent heat treatment and stress relief processes, H112 aluminum alloys have higher tensile and yield strength, making them suitable for higher load applications.

3. Applications

H111: Suitable for applications where strength requirements are not particularly high, such as hulls and other corrosion-resistant components that do not endure extreme mechanical loads.

H112: Suitable for applications requiring higher strength and better mechanical performance, such as structural components subjected to significant loads.

4. Performance Stability

H111: Performance may vary slightly, as H111 aluminum alloys are not subjected to particularly strict control.

H112: Performance is more stable and consistent, making it suitable for demanding engineering applications.

Marine aluminum products you may be interested in