5083 h112 aluminum plate for shipbuilding

Last Updated :

In the shipbuilding industry, 5083 H116/H321/H112 are commonly used for main decks, diesel engine bases, and small boat hulls. Although 5083 H112 is part of the 5083 aluminum alloy family and has no differences in chemical composition, 5083 H112 aluminum plates have been successfully applied in yachts, cruise ships, passenger ships, and cargo ships.

5083 H112 aluminum plates are a high-strength aluminum-magnesium alloy commonly used in the shipbuilding industry. Due to their excellent corrosion resistance and good weldability, 5083 aluminum alloys are particularly well-suited for marine environments.

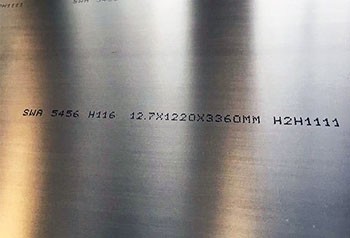

The specification of 5083 aluminium plate

- Temper: H112,H111,H116,H321

- Thickness: 0.5-500 mm

- Width: 20-2650 mm

- Length: 500-16000 mm

Characteristics of Marine Aluminum Plate 5083 H112

- 1. Corrosion Resistance: Due to its high magnesium content, 5083 aluminum plate has excellent corrosion resistance in marine environments. It effectively resists seawater corrosion, ensuring long-term durability and safety for hulls and marine structures.

- 2. Weldability: 5083 H112 aluminum plate offers excellent weldability, suitable for various welding methods such as TIG and MIG. After welding, it maintains high mechanical properties and corrosion resistance.

- 3. Machinability: The aluminum plate has good formability and can undergo various machining processes, such as cutting, bending, and stamping, making it suitable for manufacturing complex-shaped hull structures and components.

Chemical Composition of 5083 aluminum sheet plate

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.2 | 0.25 | – | – |

Al 5083 h112 mechanical properties

| Tensile strength | Yield strength | Hardness | Elongation |

| (250℃MPa) | (250℃MPa) | 500kg force 10mm ball | 1.6mm (1/16in) thickness |

| 275-350 | 210 | 65 | 16 |

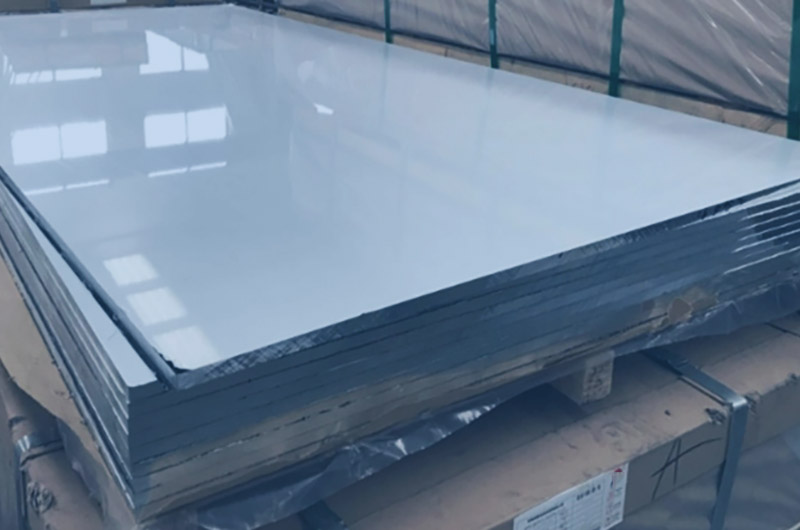

5083 h112 aluminum plate for shipbuilding industry

5083 H112 Aluminum Plate for Hulls

The 5083 H112 aluminum plate is extensively used in the construction of ship hulls, providing the necessary strength and corrosion resistance to withstand harsh marine environments. This aluminum alloy is particularly valued for its excellent performance in saltwater conditions, ensuring that the vessel maintains its structural integrity and longevity even after prolonged exposure to seawater. The H112 temper offers an optimal balance between strength and formability, making it ideal for the curved and complex shapes often required in hull designs.

5083 H112 Aluminum Plate for Decks

In shipbuilding, the 5083 H112 aluminum plate is a preferred choice for deck construction, where it must endure high-strength loads and constant exposure to corrosive elements. This alloy is known for its high yield strength, allowing it to support heavy equipment and withstand significant mechanical stresses without deforming. Additionally, its superior corrosion resistance ensures that the deck remains robust and free from deterioration, even in the most demanding marine environments.

5083 H112 Aluminum Plate for Bulkheads

When it comes to constructing ship bulkheads, the 5083 H112 aluminum plate is an indispensable material due to its reliable structural support and exceptional corrosion protection. The alloy's mechanical properties provide the rigidity and stability needed for bulkheads, which play a critical role in compartmentalizing the ship and enhancing its overall safety. The H112 temper is especially beneficial in ensuring that the bulkheads can be shaped and joined effectively while maintaining their strength and durability against the corrosive forces encountered at sea.

Marine aluminum plate 5083 h112 other applications

1. Offshore Platforms

Structural Components: 5083 H112 aluminum plates are widely used in structural components of offshore platforms, ensuring long-term stable operation in harsh marine environments with excellent strength and corrosion resistance.

2. Yacht Manufacturing

Hull Structure: 5083 H112 aluminum plates are used in yacht hull structures. Their lightweight, high strength, and corrosion resistance characteristics help enhance the yacht's speed and fuel efficiency.

3. Marine Engineering

Offshore Wind Turbine Equipment: 5083 H112 aluminum plates are used for structural components of offshore wind turbine equipment, providing high strength and corrosion protection.

What is the difference between 5083 H111 and 5083-H112?

The H112 condition provides higher performance and is suitable for applications requiring greater strength and durability, whereas the H111 condition is more commonly used in situations where lower strength is required.

| Characteristics | 5083 H111 | 5083 H112 |

| Heat Treatment and Stress Relief | Simple annealing treatment to remove processing stress | Subjected to rigorous heat treatment and stress relief |

| Mechanical Properties | Lower strength and hardness, with good machinability | Higher strength and hardness, with better mechanical properties |

| Applications | Suitable for components with lower strength requirements, such as hulls | Suitable for high-load applications, such as structural components |

| Performance Stability | Performance may vary slightly | More stable and consistent performance |

1. Heat Treatment and Stress Relief

H111: This condition typically refers to simple annealing treatment, mainly to remove stresses produced during processing. Aluminum alloys in the H111 condition are generally not subjected to extensive hardening, resulting in slightly lower mechanical properties compared to H112. However, they offer good machinability and adequate strength.

H112: This condition usually refers to more rigorous heat treatment and stress relief processes. Compared to H111, H112 has higher strength and better mechanical properties. Aluminum alloys in the H112 condition undergo treatment after processing and forming to optimize their performance.

2. Mechanical Properties

H111: The mechanical properties are relatively lower, typically used in applications with less demanding requirements. It has lower strength and hardness but provides good ductility and formability.

H112: Due to the more stringent heat treatment and stress relief process, H112 aluminum alloys have higher tensile and yield strengths, making them suitable for applications with higher loads.

3. Applications

H111: Suitable for applications where strength requirements are not very high, such as hulls and other corrosion-resistant components that do not endure extreme mechanical loads.

H112: Suitable for applications requiring higher strength and better mechanical properties, such as structural components subjected to significant loads.

4. Performance Stability

H111: Performance may vary slightly as the H111 condition does not involve particularly stringent control.

H112: Performance is more stable and consistent, making it suitable for applications with strict engineering requirements.

Marine aluminum products you may be interested in

Tags: Marine Grade Aluminum 5083 5 Series Marine Aluminum Aluminum for Shipbuilding