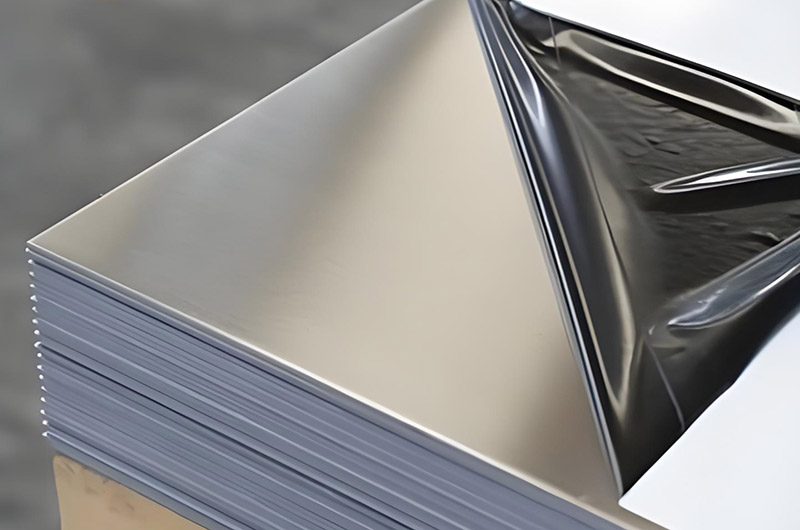

5083-H321 Aluminum Properties

Last Updated :

5083 H321 is a non-heat-treatable aluminum-magnesium alloy known for its excellent mechanical strength, weldability, and outstanding resistance to seawater and industrial corrosion.

The H321 temper indicates strain hardening followed by a low-temperature stabilization treatment, which enhances resistance to stress corrosion cracking while not significantly compromising formability. 5083-H321 is a marine-grade alloy widely used in shipbuilding, cryogenic tanks, pressure vessels, and rail vehicles.

5083 H321 aluminum has medium strength, with tensile and yield strength superior to conventional aluminum-magnesium alloys. It cannot be strengthened through heat treatment and relies on cold working to improve strength.

5083-H321 is a high-strength aluminum alloy in the 5xxx series, renowned for its excellent corrosion resistance and adaptability to marine environments. The H321 temper process involves initial strain hardening followed by stabilization to ensure dimensional stability and consistent mechanical properties.

5083 H321 Aluminum Chemical Composition

- Magnesium (Mg): 4.00 – 4.90 %

- Manganese (Mn): 0.40 – 1.00 %

- Chromium (Cr): 0.05 – 0.25 %

- Iron (Fe): 0.00 – 0.40 %

- Silicon (Si): 0.00 – 0.40 %

- Copper (Cu): 0.00 – 0.10 %

- Zinc (Zn): 0.00 – 0.25 %

- Titanium (Ti): 0.00 – 0.15 %

- Aluminum (Al): Balance

5083 H321 Aluminum Designations and Standards

- UNS: A95083

- ISO: AlMg4.5Mn

- ASTM: B209/B209M, ASME: SB209

- EN: 573-3 (Chemical Composition), 485-2 (Mechanical Properties)

5083 H321 Aluminum Physical Properties

| Property | Value |

| Density | 2 650 kg/m³ |

| Melting Point | 570 °C |

| Modulus of Elasticity (E) | 72 GPa |

| Electrical Resistivity | 0.58 × 10⁻⁶ Ω·m |

| Thermal Conductivity | 117 W/m·K |

| Coefficient of Thermal Expansion (20–212 °F) | 23.8 µm/m·°C |

5083 H321 Aluminum Mechanical Properties

- Proof (Yield) Strength: 215 – 228 MPa (minimum 215 MPa)

- Tensile Strength (Ultimate): 305 – 350 MPa (typical ~330 MPa)

- Elongation at Break: ≥ 10 % (typical 16 %)

- Brinell Hardness: ~ 89 HB

- Fatigue Strength: ~ 160 MPa

- Shear Strength: ~ 190 MPa

- Shear Modulus: 26 – 26.4 GPa

- Poisson’s Ratio: 0.33

5083 H321 Aluminum Corrosion Resistance

5083 H321 exhibits excellent resistance to seawater and a wide range of industrial chemicals, making it the alloy of choice for marine environments and corrosive atmospheres. The H321 alloy undergoes specialized exfoliation and intergranular corrosion testing in accordance with ASTM G66 and G67 standards, ensuring long-term durability for hulls and marine engineering structures.

Excellent resistance to seawater and industrial chemicals.

The stabilized H321 temper reduces susceptibility to stress corrosion cracking (SCC).

5083 H321 Aluminum Fabrication Characteristics

- Weldability: Excellent; suitable for TIG, MIG, and resistance welding with minimal strength loss.

- Formability: Good ductility allows bending, rolling, and cold working; formability in H321 is similar to H32, and best in annealed (O) condition.

- Machinability: Fair; due to its gummy texture, lubricants may be required.

5083 Aluminum Heat Treatment and Temper (H321)

- Strain Hardening: The alloy is cold worked to the desired strength (designated as H32).

- Stabilization: Low-temperature heating relieves residual stress without annealing, converting H32 to H321.

- Advantages: Enhances resistance to stress corrosion cracking and dimensional stability in welded structures.

5083 H321 Aluminum Advantages

- High strength-to-weight ratio.

- Outstanding corrosion resistance in harsh environments.

- Retains performance at low temperatures (suitable for cryogenic environments).

5083 H321 Aluminum Limitations

- Lower formability compared to softer tempers.

- Non-heat-treatable; strength is derived solely from strain hardening.

- This alloy is particularly suited for applications requiring durability in corrosive environments, prioritizing weight reduction without compromising structural integrity.

5083 H321 Aluminum Applications

- Marine and Offshore Engineering: Hulls, decks, superstructures, LNG and cryogenic storage tanks.

- Transportation: Rail vehicles, truck bodies, pressure vessels, and automotive components.

- Defense and Aerospace: Armor plates, missile engine casings, aerospace panels.

- Industrial: Chemical plant equipment, storage tanks, marine hardware.

5083 H321 Aluminum Key Standards and Specifications

| Standard | Specification |

| ASTM B209/B209M | Specification for Aluminum & Alloy Plates/Sheets |

| ASME SB209 | Boiler and Pressure Vessel Plates |

| EN 573-3 | Aluminum Alloy Chemical Composition |

| EN 485-2 | Mechanical Properties of Products |

| ISO 6361-A | Wrought Aluminum and Aluminum Alloy Sheets (all tempers) |

Further reading: 5083 marine grade aluminium checkered tread plate sheet 5083 5383 O H112 Marine Grade Aluminum Bars 5083 Marine Grade Aluminum Pipe Tube 5083 Marine Grade Aluminum Plate Sheet 5083 H321 Aluminum Plate 5083 H116 Aluminum Plate Aluminium 5083 H111 Aluminum 5083 H112 5083 Aluminum Flat Bar

Tags: Marine Grade Aluminum 5083 Marine Aluminum 5083 h321 5 Series Marine Aluminum