Characteristics of 5xxx Marine Aluminum Plates

Last Updated :

What is 5000 marine-grade aluminum?

The 5000 series marine-grade aluminum refers to aluminum alloys that use magnesium (Mg) as the primary alloying element, belonging to the Al-Mg series. These alloys are widely used in shipbuilding and marine engineering due to their excellent corrosion resistance and strength, especially in marine environments.

The 5xxx series aluminum plates are known for their outstanding corrosion resistance, high strength, weldability, fatigue resistance, lightweight properties, formability, and low-temperature performance. These attributes make them essential materials in shipbuilding, marine engineering, and offshore platforms.

The 5xxx series aluminum-magnesium alloys share some common characteristics: first, they have good corrosion resistance; second, they exhibit excellent formability and weldability; and third, they possess good strength. These properties make them widely used in industries that require corrosion resistance, such as marine vessels and ships that come into contact with seawater.

After aluminum was used to replace steel in naval ships and marine vessels, the first noticeable benefit is a significant reduction in weight. Secondly, their corrosion resistance compensates for the failures caused by corrosion in steel. This makes them widely applicable in shipbuilding, especially with 5083 alloy.

Common 5000 Series Marine-Grade Aluminum Alloys

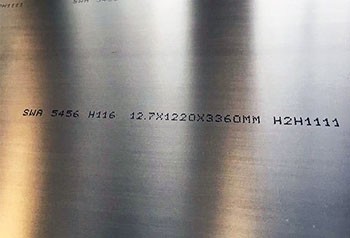

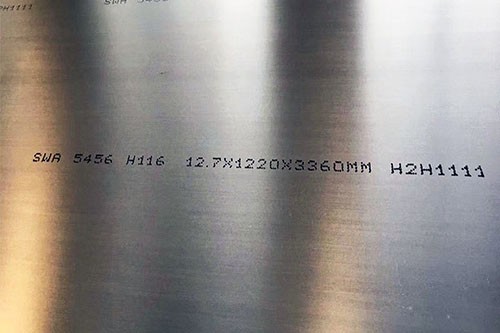

The main 5000 series marine-grade aluminum alloys include 5083, 5086, and 5456. The 5083 aluminum plate is a typical representative of the 5xxx series aluminum alloys and comes in various tempers such as O, H111, H112, H116, and H321.

- 5083: The most typical 5000 series aluminum alloy, widely used in ship structure components, offering excellent corrosion resistance and strength.

- 5086: Similar to 5083 but with even better corrosion resistance under certain conditions.

- 5456: Often used in applications that require higher strength, such as load-bearing structures of ships.

- 5052 and 5454: Commonly used for hull plating, decks, pressure vessels, and pipelines.

Other 5xxx series aluminum alloys, such as 5052, 5086, 5454, and 5456, are also commonly used in hull structures, pressure vessels, pipelines, and decks. Generally, the thickness of marine aluminum plates is determined by the hull structure, ship specifications, and usage areas. From a lightweight perspective, thinner plates are preferred, but the corrosion depth during use must also be considered.

Marine aluminum products you may be interested in

What are the characteristics of 5000 series aluminum?

- High Corrosion Resistance: The high magnesium content in the 5000 series aluminum gives it strong resistance to corrosion in seawater and atmospheric conditions, making it ideal for marine environments.

- Good Strength: Despite aluminum's low density, the 5000 series alloys have high strength, capable of withstanding the mechanical stresses required in ship structures.

- Low-Temperature Performance: This series of aluminum plates maintains good mechanical properties even at low temperatures, making them suitable for polar marine environments.

- Excellent Weldability: The 5000 series aluminum is easy to weld and is compatible with various welding processes, such as argon arc welding and gas shielded welding, while retaining good mechanical properties after welding.

- Good Fatigue Resistance: The 5000 series aluminum maintains structural integrity under prolonged vibration and fatigue loads, making it highly suitable for ship structures.

- Lightweight: The low density of aluminum makes the 5000 series alloys lighter than steel, contributing to reduced ship weight and improved fuel efficiency.

- Good Formability: The 5000 series aluminum is easy to form, allowing for the manufacture of complex components through various forming processes.

What is the strongest 5000 series aluminum?

Among the 5000 series aluminum alloys, 5456 aluminum alloy is generally considered the strongest. Compared to other 5000 series alloys, 5456 has higher strength while maintaining good corrosion resistance and weldability. This makes it widely used in marine engineering and ship structures where higher strength is required, particularly in load-bearing components.

5456 aluminum alloy is often used in the construction of high-load-bearing ship structures, offshore platforms, pressure vessels, and other marine engineering equipment.

What is the best marine-grade aluminum?

The choice of the "best" marine-grade aluminum depends on specific application scenarios and requirements. Different marine-grade aluminum alloys have their own advantages and are suitable for various conditions and uses.

5083 aluminum alloy is often considered the "best" marine-grade aluminum because it strikes a good balance between strength, corrosion resistance, and weldability, making it widely applicable to critical parts in various shipbuilding applications. If higher strength is required, 5456 aluminum alloy may be selected.

Deciding on the "best" aluminum material for marine applications usually depends on the specific application needs, environmental conditions, and the design requirements of the vessel.

Tags: Marine Grade Aluminum 5083 Marine Grade Aluminum 5052 Marine Aluminum 5754 Marine Aluminum 5059 Marine Aluminum 5454 Marine Aluminum 5456 Marine Aluminum 5383 Marine Aluminum 5086 5 Series Marine Aluminum