Marine grade 5052 checker aluminum plate for ship decks

Last Updated :

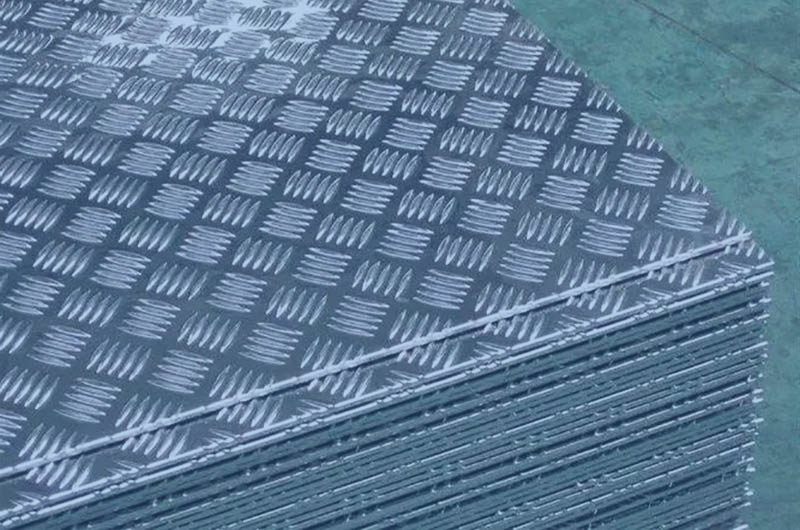

The deck is the plane structure above the internal bottom surface of the hull, used to cover the internal space of the ship. Marine grade 5052 checker aluminum plate is extensively used for ship decks and other applications where anti-slip performance and high corrosion resistance are required.

5052 aluminum alloy checker plate is commonly used for ship decks, particularly the aluminum plates with a five-bar pattern. The embossed surface of the aluminum plate provides good anti-slip properties, enhancing deck safety.

Material Characteristics of Marine Grade 5052 Checker Aluminum Plate

- Aluminum Alloy Type: 5052

- Main Advantages: Excellent corrosion resistance, wear resistance, and strength

- Suitable Environment: Particularly suited for marine environments and ship use

Specifications of Marine Grade 5052 Checker Aluminum Plate for Ship Decks

- Surface Pattern: Common checker patterns include diamond, bar, etc. Diamond patterns offer better anti-slip performance, suitable for high-demand ship decks.

- Thickness: Customizable according to specific needs, common range from 2mm to 10mm.

- Width: Customizable, common widths include 1000mm, 1200mm, 1500mm, etc.

- Length: Customizable, can be up to 6000mm or longer.

- Customization Options: Thickness, width, and length can be customized according to specific requirements.

Types of Marine Grade 5052 Checker Aluminum Plate

5 Bar Marine Grade 5052 Checker Aluminum Plate

- Description: This pattern consists of five parallel bars with evenly spaced intervals. It provides good anti-slip performance and aesthetics, suitable for high-strength environments such as ship decks and industrial platforms.

- Application: Commonly used in areas requiring high anti-slip performance and durability, such as ship decks and heavy equipment surfaces.

3 Bar Marine Grade 5052 Checker Aluminum Plate

- Description: This pattern includes three parallel bars with wider spacing than the five-bar pattern. Compared to the five-bar pattern, the three-bar design provides slightly less anti-slip performance but still offers good aesthetics and strength.

- Application: Suitable for areas requiring good anti-slip properties, commonly used in moderate-strength environments such as walkways and light-duty platforms.

2 Bar Marine Grade 5052 Checker Aluminum Plate

- Description: Featuring two parallel bars, this pattern offers basic anti-slip performance with wider bars, suitable for applications needing a simple appearance.

- Application: Suitable for areas with lower anti-slip requirements, commonly used in decorative applications or light-load areas.

Diamond Marine Grade 5052 Checker Aluminum Plate

- Description: The surface features a diamond pattern, providing outstanding anti-slip performance and high aesthetics. The diamond pattern is evenly distributed, offering strong anti-slip and wear resistance.

- Application: Suitable for high anti-slip requirements, such as ship decks, cargo areas, and other surfaces needing high anti-slip performance.

Advantages of Marine Grade 5052 Checker Aluminum Plate

Corrosion Resistance

Excellent Salt Spray Corrosion Resistance: 5052 aluminum alloy has exceptional resistance to salt spray corrosion, effectively resisting salt penetration in marine environments. This feature enhances longevity in seawater and moist environments.

Suitable for Long-Term Marine Use: Due to its superior corrosion resistance, 5052 aluminum alloy is ideal for prolonged exposure to seawater, such as ship decks and marine platforms, with minimal rust or corrosion.

Strength

Higher Strength Than Pure Aluminum: Compared to pure aluminum, 5052 aluminum alloy offers higher strength, capable of bearing heavier loads. Its tensile strength and fatigue resistance make it ideal for structural applications.

Capable of Supporting Heavier Loads: Due to its high strength, 5052 aluminum alloy provides reliable support in ship decks and other heavy-load areas, suitable for bearing the weight of ships and equipment.

Workability

Good Machinability: 5052 aluminum alloy has good machinability, allowing for easy cutting, welding, and forming. This facilitates more efficient and convenient manufacturing and installation.

Easy Welding and Fabrication: Its excellent weldability makes welding operations easier when constructing complex structures, improving production efficiency and quality.

Lightweight

Lighter Weight: 5052 aluminum alloy has a lower density compared to other metals, making it lighter. This helps reduce the overall weight of the ship.

Helps Reduce Ship Weight and Improve Fuel Efficiency: Reducing the weight of the ship not only lowers transportation and manufacturing costs but also improves fuel efficiency, thus reducing operational costs and environmental impact.

Applications of Marine Grade 5052 Checker Aluminum Plate

Marine grade 5052 checker aluminum plate provides excellent anti-slip performance, suitable for anti-slip and durability requirements of ship decks.

Other Applications:

- Spiral staircases for large ships

- Treads and flooring

- Work platforms

Mechanical properties of 5052 marine aluminium

| Alloy | Temper | Sample temper | Thickness mm | Tensile strength RmMPa | Extension strength RP0.2/Mpa | Elongation % | |

| A50 mm | A | ||||||

| 5052 | O | O | 3.00-6.00 | 175-215 | ≥65 | ≥18 | |

| >6.00-50.00 | 170-215 | ≥65 | ≥19 | ||||

| H111 | H111 | 3.00-6.00 | 175-215 | ≥65 | ≥18 | ||

| >6.00-50.00 | 170-215 | ≥65 | ≥19 | ||||

| H22, H32 | H22, H32 | 3.00-6.00 | 210-260 | ≥130 | ≥10 | ||

| H112 | H112 | 6.00-12.50 | ≥190 | ≥80 | ≥7 | ||

| >12.50-50.00 | ≥170 | ≥70 | - | ||||

Chemical composition of 5052 marine grade aluminum plate

| Element | Chemical composition (%) |

| Al | Rem |

| Si | ≤0.25 |

| Fe | ≤0.50 |

| Cu | ≤0.10 |

| Mn | ≤0.10 |

| Mg | 2.2-2.8 |

| Cr | 0.15-0.35 |

| Zn | ≤0.10 |

| Note:Each:≤0.05;Total:≤0.15 | |

Marine aluminum products you may be interested in