Marine Aluminum Alloy Product Types

Last Updated :

Marine aluminum alloy products include plates, profiles, tubes, bars, forgings, and castings.

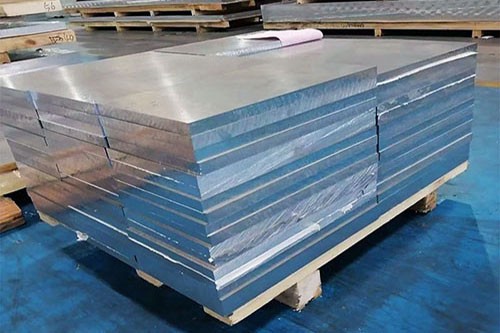

Marine Aluminum Plates

The thickness of marine aluminum plates depends on multiple factors, including the hull structure, ship specifications, and usage areas. To achieve lightweight hull designs, thinner aluminum plates are preferred, but the potential corrosion depth during the usage period must also be considered.

The thickness of marine plates is determined by the hull structure, ship specifications, and usage areas. From a lightweight perspective, it is advisable to use thinner plates, while also considering the corrosion depth during the usage period.

Thickness Selection for Marine Aluminum Plates

- Thin Plates: Typically 1.6mm and above, suitable for lightweight hull structures.

- Thick Plates: Typically 30mm and above, suitable for areas requiring high strength.

Width Specifications for Marine Aluminum Plates

- Standard Width: Commonly used width is 2.0m, suitable for most ship needs.

- Large Vessels: Plates up to 2.5m in width can be used to reduce welding seams and improve structural stability.

Length Specifications for Marine Aluminum Plates

Standard Length: Generally 6m, but special specifications can be provided based on shipyard contract requirements.

Anti-slip Design for Marine Aluminum Plates

Deck Pattern Plates: To enhance safety, patterned aluminum plates are usually used on decks to increase friction during walking and prevent slipping.

Considerations

- Lightweight: Use thinner plates in hull design to reduce overall weight.

- Corrosion Depth: When selecting plate thickness, consider the possible corrosion during use to ensure safety and durability.

Marine Aluminum Profiles

The profiles used in ships include the following types:

Symmetrical Marine Grade Aluminum Bulb Flat Extrusions

- Height: 40~300mm

- Features: Symmetrical design, suitable for structural support and connection areas.

Asymmetrical Marine Grade Aluminum Bulb Flat Extrusions

- Height: 40~200mm

- Features: Asymmetrical design, providing different load-bearing capacities for specific structural needs.

Marine Grade Flat Aluminum

- Thickness: 3~80mm

- Width: 7.5~250mm

- Features: Various thicknesses and widths available, suitable for different manufacturing and design requirements.

Same-direction Round-headed Marine Grade Angular Aluminum

- Height: 70~400mm

- Features: Round-headed design, providing good strength and rigidity, suitable for frame structures.

Inverse Round-headed Marine Grade Angular Aluminum

- Height: 35~120mm

- Features: Inverse round-headed design, suitable for structures requiring special fittings.

Equal-sided Marine Grade Angular Aluminum

- Specifications: 15mm x 15mm ~ 200mm x 200mm

- Features: Equal side lengths, suitable for constructing balanced frames and support structures.

Unequal-sided Marine Grade Angular Aluminum

- Specifications: 20mm x 15mm ~ 200mm x 120mm

- Features: Unequal side lengths, suitable for special design requirements.

Marine Grade Aluminum Trough

- Specifications: Flange 25mm x 45mm, web 40mm x 250mm

- Features: Channel design, suitable for connecting and installing various components.

Marine Grade T-Type Aluminum

- Specifications: 60mm x 200mm x 8/5, 60mm x 150mm x 5/4

- Features: T-shaped structure, providing strength and rigidity for various applications.

These aluminum profiles play a vital role in the frame structures, connections, and other components of ships, ensuring safety and durability.

In addition to the regular profiles mentioned above, ships also use special profiles. Some ships use integrated wall panels where reinforcing ribs are rolled (or extruded) into the plate, which can be shaped into flat or tubular forms. Tubes can be cut open along the axis and then flattened. The integrated extruded wall panels used in ships have higher ribs and wider rib spacing compared to those used in aircraft, with widths of 1~2m and lengths of 4~6m, and can be as long as 15m. The use of integrated wall panels allows for adjustments to the thickness of outer plates and longitudinal beams, ensuring optimal stress distribution for a reasonable structure, reducing weight, minimizing the number of weld seams, and decreasing warping after welding.

Marine Aluminum Tubes and Bars, and Others

Marine Aluminum Tubes

- Uses: Small diameter aluminum alloy tubes are typically used for piping, while larger diameter tubes are used for hulls, superstructures, masts, and columns (such as hollow round columns and hollow angled columns).

- Specifications: Common tube outer diameters range from 16-150mm, with wall thicknesses of 3-8mm.

- Considerations: When selecting tube thickness, it is essential to consider strength and the impact of corrosive media to ensure safety and reliability for long-term use.

Marine Aluminum Bars

- Uses: Primarily used for manufacturing structural and connection components.

- Specifications: Diameter range from 12~100mm, common alloys include 5052, 5056, and 5083.

Other Marine Aluminum Materials

Forgings and castings: Their use in ships is relatively less, mainly for certain machinery components and specific structural needs.

These aluminum materials play a crucial role in shipbuilding, ensuring structural strength, lightweight characteristics, and corrosion resistance.

Marine aluminum products you may be interested in

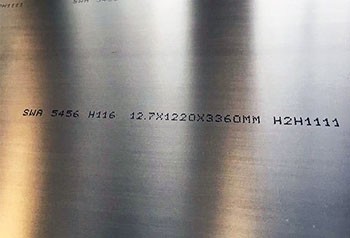

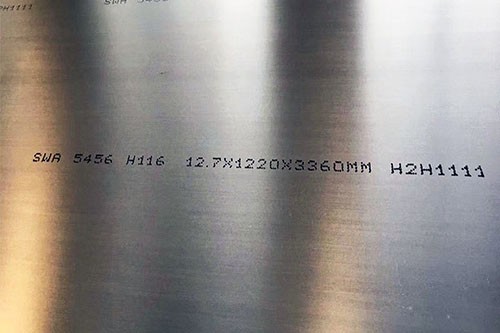

Tags: 5 Series Marine Aluminum 6 Series Marine Aluminum Marine Grade Aluminum 5083 Marine Grade Aluminum 5052 Marine Aluminum 5059 Marine Aluminum 6061 Marine Aluminum 5456 Marine Aluminum 5454 Marine Aluminum 6082