Marine Aluminum Alloys

Last Updated :

Almost all types of aluminum and aluminum alloys are used in ships.

Currently, the most commonly used alloys are:

- 5xxx series (5052, 5154, 5454, 5754, S083, 5283, 5086, 5056, 5456, 5005, etc.)

- 6xxx series (6063, 6060, 6061, 6070, 6082, 6N01, 6005, 6005A, 6351, etc.)

- 7xxx series (7005, 7039, etc.)

- 1xxx series (1050, 1100, 1200, etc.)

- 3xxx series (3001, 3023, etc.)

- 4xxx series (4043, 4032, etc.)

- Deformed aluminum alloys and cast aluminum alloys such as AC4A, AC4C, AC4CH, AC7A, AC8A, etc.

| Aluminum Alloy Series | Common Alloys | Characteristics | Applications |

| 5xxx Series | 5052, 5154, 5454, 5754, 5083, 5086, 5056, 5456, 5005 | Excellent corrosion resistance | Hull structures, marine applications |

| Easy to weld, good weld joint strength | |||

| Medium strength, suitable for hulls, upper structures, and compartments | |||

| 6xxx Series | 6063, 6060, 6061, 6070, 6082, 6005, 6005A, 6351 | High tensile strength | Frames, structural components, decks |

| Good extrudability, suitable for complex shapes | |||

| Good corrosion resistance | |||

| 7xxx Series | 7005, 7039, 7010, 7015, 7079 | High strength, suitable for high-load structures | Masts, load-bearing frames |

| Some alloys have poor weldability, requiring special welding techniques | |||

| Suitable for components with extremely high load requirements | |||

| 1xxx Series | 1050, 1100, 1200 | Aluminum content over 99%, excellent corrosion resistance | Interior fittings, decorative parts, insulation materials |

| Lower strength, suitable for lightly loaded components | |||

| 3xxx Series | 3001, 3003, 3023 | Excellent machinability | Ship interior components, piping |

| Good weldability, suitable for compartments and internal structures | |||

| 4xxx Series | 4043, 4032 | Mainly used for welding filler materials | Welding materials, aluminum alloy repair processes |

| Lower melting point, suitable for low-temperature welding |

5xxx Series Marine Aluminum Alloys

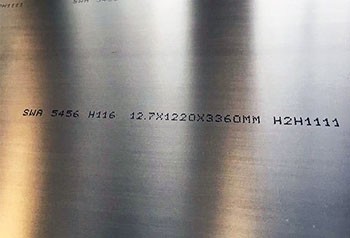

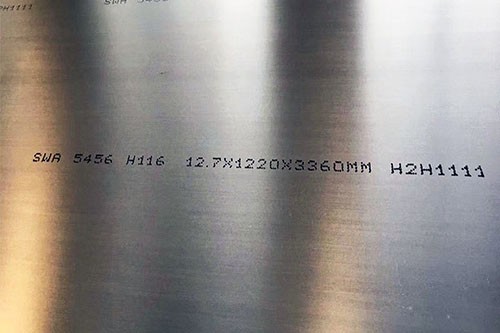

Common Alloys: 5052, 5154, 5454, 5754, 5083, 5086, 5056, 5456, 5005, etc.

Characteristics:

- Corrosion Resistance: Excellent resistance to seawater corrosion, suitable for ship structures and marine applications.

- Weldability: Easy to weld, with good weld joint strength, suitable for hull welding.

Strength: Medium strength, suitable for load-bearing components such as hulls, upper structures, and compartments.

6xxx Series Marine Aluminum Alloys

Common Alloys: 6063, 6060, 6061, 6070, 6082, 6005, 6005A, 6351, etc.

Characteristics:

- Strength: Higher tensile strength, suitable for load-bearing components such as frames and structural parts.

- Extrudability: Good extrudability, facilitating the manufacture of complex shapes, widely used in decks, support beams, etc.

- Corrosion Resistance: Although not as good as the 5xxx series, still possesses good corrosion resistance, suitable for interior fittings and decorations.

7xxx Series Marine Aluminum Alloys

Common Alloys: 7005, 7039, etc.

Characteristics:

- High Strength: The highest strength series among all aluminum alloys, suitable for high-load structures.

- Weldability: Some alloys have poor weldability and typically require special welding techniques, suitable for components with extremely high load requirements.

Applications: Commonly used in masts, frames, and other load-bearing structures.

1xxx Series Marine Aluminum Alloys

Common Alloys: 1050, 1100, 1200, etc.

Characteristics:

- High Purity: Aluminum content over 99%, with excellent corrosion resistance.

- Strength: Lower strength, mainly used for lightly loaded components.

Applications: Commonly found in interior fittings, decorative parts, and insulation materials.

3xxx Series Marine Aluminum Alloys

Common Alloys: 3001, 3003, 3023, etc.

Characteristics:

- Formability: Excellent processing and forming properties, suitable for complex shapes.

- Weldability: Good weldability, suitable for compartments and internal structures.

Applications: Commonly used in ship interior components, piping, etc.

4xxx Series Marine Aluminum Alloys

Common Alloys: 4043, 4032, etc.

Characteristics:

- Welding Material: Mainly used for welding filler materials, enhancing the performance of weld joints.

- Low Melting Point: Lower melting point, suitable for welding at lower temperatures.

Applications: Widely used in welding and repair processes for aluminum alloys.

The selection and application of these aluminum alloys aim to ensure the structural strength, corrosion resistance, and overall performance of ships, meeting the demands of various marine environments.

The main types of aluminum plates include thick plates, medium-thick plates, thin plates, strips, and foils. The main aluminum materials include pipes, bars, profiles, solid rib plates, and hollow rib plates.

With the trend of larger and lighter hulls, along with advancements in aluminum processing technology, the application of large extruded profiles and pipes, large wide aluminum plates, thick aluminum plates, large forgings, and large castings is becoming increasingly widespread.

The thickness of large marine aluminum plates typically ranges from 2 to 15 mm, with a maximum thickness exceeding 100 mm. The thinnest can reach 0.2 mm (thin aluminum plates) and 0.005 to 0.2 mm (aluminum foils). The width of aluminum strips generally ranges from 1000 to 3000 mm, with a maximum width of up to 5000 mm.

Marine aluminum products you may be interested in

Tags: 5 Series Marine Aluminum 6 Series Marine Aluminum Marine Grade Aluminum 5083 Marine Grade Aluminum 5052 Marine Aluminum 6061 Marine Aluminum 5059 Marine Aluminum 6082 Marine Aluminum 5456 Aluminum for Shipbuilding Aluminum for Boat