Four golden rules for purchasing marine aluminum plates

Last Updated :

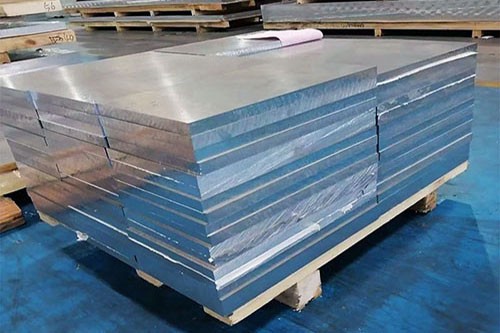

Aluminum plates are becoming more and more widely used, and more products in the field of machinery manufacturing are beginning to use aluminum plates as their raw materials. The shipbuilding industry has an increasing demand for aluminum plates, but how to choose good marine aluminum plates?

Marine aluminum plates are one of the emerging fields of aluminum plate products. Since marine aluminum plates are used in marine vessels and other fields, they have more stringent process requirements and performance standards than other ordinary aluminum plate products.

Four golden rules for selecting marine aluminum plates

1. High specific strength and specific modulus

The structural strength and size of the ship are closely related to the yield strength and elastic modulus of the material. Since the elastic modulus and density of the aluminum plate are roughly the same, the addition of alloy elements has little effect. Therefore, increasing the yield strength within a certain range is beneficial to reducing the weight of the ship. The structure is favorable. It is usually difficult for high-strength aluminum plates to have both excellent corrosion resistance and weldability. Therefore, marine aluminum plates are generally medium-strength, corrosion-resistant and weldable alloys.

2. Excellent welding performance

At present, the automatic argon arc welding method is mainly used in ships. Good weldability means that the tendency of cracks formed by aluminum plates during welding is smaller, which means that aluminum plates must have good welding crack resistance. Because the lost welding performance cannot be restored by heat treatment again under shipbuilding conditions.

3. Excellent corrosion resistance

Ship structures are used in more or less harsh seawater media and marine environments. Therefore, corrosion resistance is one of the main signs of marine alloys.

4. Aluminum plate has good cold and hot forming properties

Since ship manufacturing requires a variety of cold processing and hot processing, marine aluminum plates must be easy to process and shape, without crack defects, and still meet the strength and corrosion resistance requirements after processing.

Advantages of marine aluminum plates

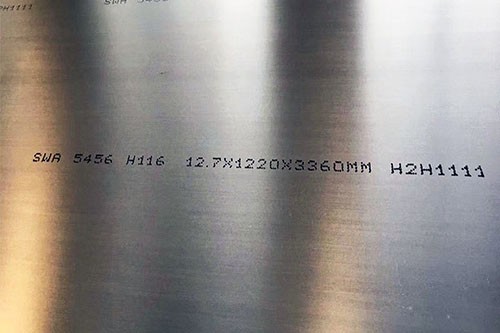

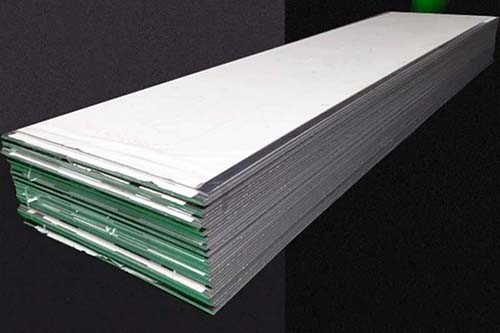

The material selection of marine aluminum plates is relatively strict. At present, aluminum plate products such as 5083, 5086, 5454, 5754, and 6061 are mostly used. In practical applications, the advantages of marine aluminum plates are very obvious.

1. Light specific gravity, reducing ship weight, saving energy consumption, and increasing load capacity

The specific gravity of aluminum is relatively small, and the use of aluminum plates can significantly reduce the weight of the ship compared with traditional steel. In this way, the fuel consumption of the ship will be reduced accordingly, thereby saving energy consumption. At the same time, due to the reduced weight of the ship, the loading weight of the ship can be increased, and its cargo capacity or crew capacity can be improved.

2. Good corrosion resistance, reducing oiling and other costs and extending service life

Aluminum has good corrosion resistance, especially in seawater environment, its corrosion resistance is even more outstanding. In contrast, steel is easily affected by oxidation and corrosion in seawater and requires frequent anti-corrosion treatment. The use of aluminum plates can reduce maintenance costs in this area. Therefore, the use of marine aluminum plates can extend the service life of the hull.

3. Good welding, processing and forming performance, which is conducive to later processing

Aluminum has good machinability and can be processed and formed into various shapes. Various welding, bending, forming and other operations are required in ship hull manufacturing. These characteristics of aluminum plates make them more flexible in the ship manufacturing process and can meet the manufacturing needs of hull structures with different shapes and requirements.

4. Easy to recycle, recyclable and safe

Aluminum is a recyclable material, and scrap aluminum products can be processed again through recycling. This recyclability not only helps reduce resource consumption, but also reduces environmental pollution. In addition, aluminum does not burn when exposed to flames, so it also has safety advantages, helping to reduce the risk of fires.

Marine aluminum products you may be interested in

Marine Grade Aluminum Materials for Ship Structure

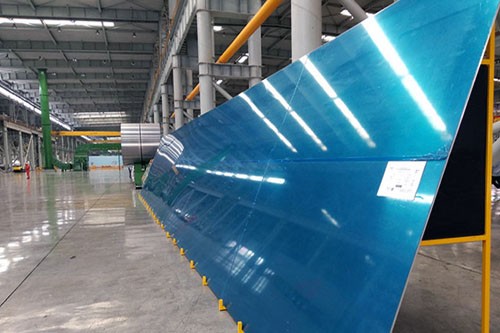

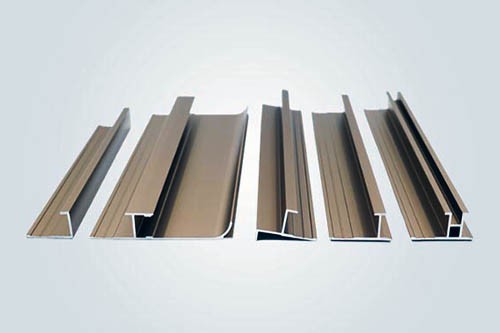

Haomei Aluminum is a manufacturer dedicated to the production and sales of ship plates, marine aluminum welding wires, marine aluminum profiles and other marine-related products, with guaranteed quality and competitive prices.

To sum up, the advantages of marine aluminum plates in ship manufacturing and operation are obvious, and can bring many benefits to the shipbuilding industry, including energy saving and emission reduction, extending ship service life, improving production efficiency, etc.

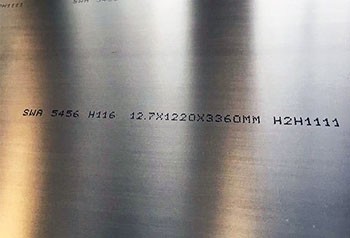

Tags: Marine Grade Aluminum 5083 Marine Grade Aluminum 5052 Marine Aluminum 5754 Marine Aluminum 5059 Marine Aluminum 5454 Marine Aluminum 5456 Marine Aluminum 5383 Marine Aluminum 5086 5 Series Marine Aluminum 6 Series Marine Aluminum