5052 Marine Grade Aluminum Plate Sheet

5052 marine grade aluminum plate is a high quality aluminum alloy known for its excellent corrosion resistance and excellent weldability. It belongs to the 5xxx series of aluminum alloys, known for its excellent combination of strength and formability.

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

Is 5052 aluminum good for boats?

The 5052 aluminum is suitable for freshwater vessels, as the corrosion level of aluminum plates in freshwater environments is relatively low. A commonly used material is the 5052 aluminum plate. This is a rust-resistant aluminum alloy with good corrosion resistance and forming properties, making it ideal for small freshwater vessels. While it offers a certain level of strength, it may not meet the strength requirements for larger yachts or ships, so it is more suitable for building small freshwater boats.

What is 5052 marine grade aluminum plate?

5052 marine grade aluminum plate is an aluminum alloy plate mainly used in shipbuilding and marine engineering. The main component of 5052 marine grade aluminum plate is aluminum, and magnesium is the main alloy element. It is strengthened by cold working to enhance its mechanical properties without affecting its corrosion resistance.

5052 Marine Grade Aluminum Plate Sheet has excellent corrosion resistance, aging resistance and weldability, so it performs well in marine environments. It is commonly used in the manufacture of hulls, decks, ship floors, ship tanks and other parts that require corrosion resistance.

Why Choose 5052 Marine Grade Aluminum Plate?

- 1. Excellent corrosion resistance: Excellent corrosion resistance in marine environments, extending service life and reducing maintenance costs.

- 2. High strength-to-weight ratio: Provides structural integrity while keeping weight to a minimum, improving performance and efficiency in marine and transportation applications.

- 3. Ease of fabrication: Can be easily machined, welded and formed, allowing for cost-effective fabrication and customization to specific project requirements.

- 4. Proven performance: Widely used and trusted in the marine industry for its reliability, durability and service life in harsh marine environments.

5052 Marine Grade Aluminum Plate Sheet Benefits

- Corrosion Resistance: Exhibits excellent corrosion resistance in marine environments, making it ideal for long-term exposure to seawater.

- High Strength: Provides a good strength-to-weight ratio, providing structural integrity while maintaining lightweight properties.

- Weldability: Easily welded using conventional methods, allowing for seamless fabrication and repair.

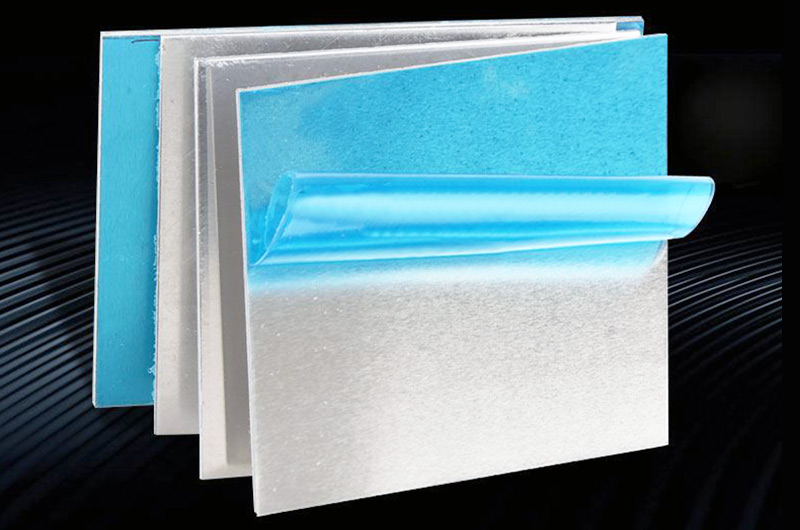

- Formability: Can be formed into a variety of shapes and sizes without affecting its mechanical properties, providing design versatility.

- Low Density: Lightweight properties reduce overall weight in marine and transportation applications, helping to improve fuel efficiency and payload capacity.

5052 Marine Grade Aluminum Plate Sheet Performance Features

- 1. 5052 aluminum has a tensile strength between 210 and 230, which refers to its ability to withstand tensile force .

- 2. 5052 aluminum plate is between 12% and 20%, which indicates the degree of deformation it can withstand during the stretching process. This is an important specification, especially for applications that require bending or forming.

- 3. The role of chromium in 5052 aluminum is similar to that of manganese, which can improve its ability to resist stress corrosion cracking. But unlike manganese, the content of chromium generally does not exceed 0.35%. Additionally, the role of manganese in 5052 aluminum is more to enhance welding properties than to increase the strength of the base metal and weld.

- 4. 5052 aluminum has good corrosion resistance, excellent weldability, good cold workability and medium strength. These characteristics make it widely used in many industries. In addition, a similar aluminum alloy is 5083 aluminum plate, which has similar characteristics but is more suitable for applications in marine environments because of its higher corrosion resistance.

- 5. 5052 aluminum has good plasticity when semi-cold work hardening, but has low plasticity when cold work hardening. It cannot be further strengthened by heat treatment.

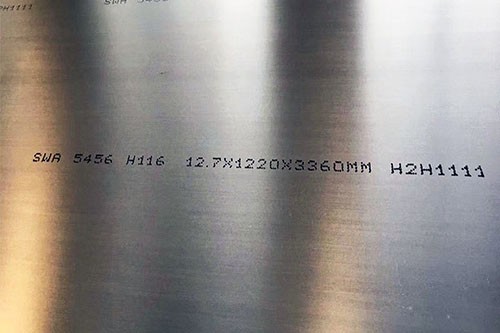

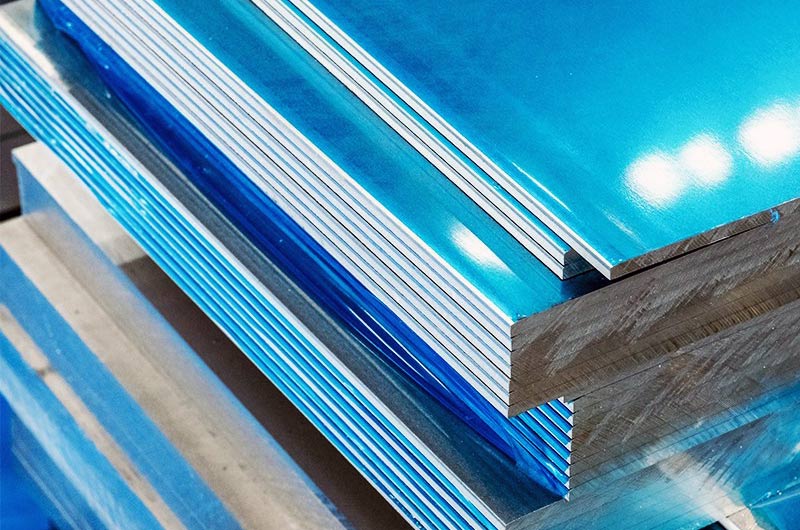

5052 Marine Grade Aluminum Plate Sheet Specifications

- Alloy: 5052

- Status: O, H32, H34, H36, H38

- Thickness: Typically ranges from 0.2mm to 300mm

- Width: up to 2650mm

- Length: customized according to application requirements

- Surface treatment: milled, polished or coated according to customer preference

- Standard: ASTM B209-10, AMSQQA250/8, ASTM B928/B928M-15 ASTM B928/B928M-21 ISO 12215-5:2019

- Classification society certification: CCS, DNV, NK, CCS, ABS, BV, LR, KR

- Equivalent name: A5052, 5052a, aa5052, 5052aa, al5052, al5052a, 5052 aa, aa 5052, jis a5052p, al5052 class, aw5052, en5052 grade etc

5052 Marine Grade Aluminum Plate Sheet Mechanical Properties

| Alloy Temper | Specified thickness | Tensile strength | Yield strength | Elongation |

| (MPa) | (MPa) | (%) | ||

| 5052 HO/H111 | 0.3~0.63mm | 173-213 | min66 | min 15 |

| 0.63~1.2mm | min 17 | |||

| 1.2~6.3mm | min 19 | |||

| 6.3~50mm | min 18 | |||

| 5052/H32 or 5052 H22 | 0.4~0.63mm | 214-262 | min159 | min 4 |

| 0.63~1.2mm | min 5 | |||

| 1.2~6.3mm | min 7 | |||

| 6.3~50mm | min 11 | |||

| 5052/H34 or 5052 H24 | 0.4~0.63mm | 235-282 | min180 | min 3 |

| 0.63~1.2mm | min 4 | |||

| 1.2~6.3mm | min 6 | |||

| 6.3~50mm | min 10 | |||

| 5052/H36 or 5052 H26 | 0.1~0.32mm | 256-303 | min200 | min 2 |

| 0.32~0.63mm | min 3 | |||

| 0.63~4mm | min 4 | |||

| 5052/H38 or 5052 H28 | 0.15~0.32mm | min269 | min221 | min 2 |

| 0.32~0.63mm | min 3 | |||

| 0.63~3.2mm | min 4 |

Chemical composition of marine grade 5052 alloy aluminium sheet plate

| Al | Allowance |

| Si | ≤0.25 |

| Cu | ≤0.10 |

| Mg | 2.2~2.8 |

| Zn | ≤0.10 |

| Mn | ≤0.10 |

| Cr | 0.15~0.35 |

| Fe | ≤0.40 |

| single | ≤0.05 |

| total | ≤0.15 |

5052 Marine Grade Aluminum Plate Sheet Marine Application Examples

5052 marine aluminum plate is the material of choice for high-speed ships, such as fast ferries, yachts, offshore ships, etc. It is widely used in the manufacture of ship sheet metal parts, bottom plates, portholes, bottom plates and side plates.

Hull: Used in the construction of ship hulls due to its corrosion-resistant and lightweight properties, ensuring longevity and fuel efficiency.

Marine Components: Used in marine components such as propeller shafts, rudders and accessories where corrosion resistance is critical for extended service life.

Offshore structures: used in the fabrication of offshore platforms, pipelines and marine infrastructure where durability and resistance to harsh marine environments are critical.

Structural components: Due to its strength and lightweight properties, it is widely used in the construction of structures such as gangways, decks and offshore platforms.

Marine Fuel Tanks: 5052 H32 marine grade aluminum can be used to manufacture marine fuel tanks. Fuel tanks are important equipment for storing marine fuel, lubricants and other liquids. The high strength and good sealing performance of 5052 plates make it an ideal material for manufacturing reliable and durable marine fuel tanks.

Ship air conditioners: Compared with land air conditioners, ship air conditioners operate in oceans with high humidity and high corrosion for a long time. To prevent sheet metal corrosion, 5052 aluminum plate is a good choice.

In addition to being used as ship plates, 5052 aluminum plates can also be used in ship cable trays, ship storage tanks, cabin floors, etc.

Small freshwater lake yachts generally use 5052-H32 aluminum plates or 5052-O aluminum plates because fresh water is not as corrosive as seawater. Mainly used for yacht hulls.

In conclusion, 5052 marine grade aluminum plate is a versatile and reliable material suitable for a wide range of marine and industrial applications. Its superior corrosion resistance, combined with its strength, lightweight and ease of fabrication, make it the first choice for marine structural, transportation and construction projects where durability and performance are critical.

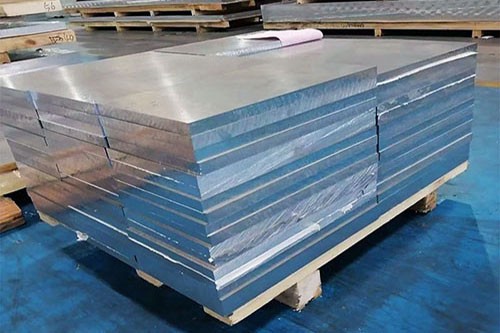

5052 Marine Grade Aluminum Plate Sheet Popular Stock Sizes

| Product | Size |

| 5052 O Marine Grade Aluminum Plate Sheet | 12" X 12" |

| 5052 O Marine Grade Aluminum Plate Sheet | 12" X 36" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 24" X 48" |

| 5052 O Marine Grade Aluminum Plate Sheet | 24" X 24" |

| 5052 O Marine Grade Aluminum Plate Sheet | 36" X 36" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 12" X 36" |

| 5052 O Marine Grade Aluminum Plate Sheet | 24" X 36" |

| 5052 O Marine Grade Aluminum Plate Sheet | 24" X 48" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 12" X 24" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 36" X 48" |

| 5052 O Marine Grade Aluminum Plate Sheet | 48" X 48" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 12" X 12" |

| 5052 O Marine Grade Aluminum Plate Sheet | 36" X 48" |

| 5052 O Marine Grade Aluminum Plate Sheet | 12" X 48" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 24" X 24" |

| 5052 O Marine Grade Aluminum Plate Sheet | 48" X 144" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 48" X 48" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 12" X 48" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 24" X 36" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 48" X 144" |

| 5052 O Marine Grade Aluminum Plate Sheet | 12" X 24" |

| 5052 H32 Marine Grade Aluminum Plate Sheet | 36" X 36" |

Marine aluminum products you may be interested in

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5059 Marine Grade Aluminum Plate Sheet

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5383 Marine Grade Aluminum Plate Sheet

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

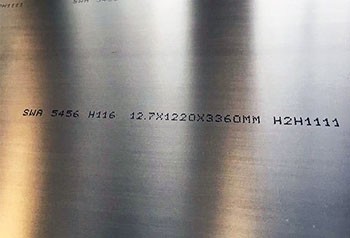

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5052 marine grade aluminium checkered tread plate sheet

5052 Marine Grade Aluminum Checkerboard combines superior corrosion resistance, enhanced traction, lightweight construction and versatility, making it ideal for a variety of marine applications where durability and safety are critical.

-

5052 O H112 Marine Grade Aluminum Bar

5052 O H112 Marine Grade Aluminum Rod is a rod made from 5052 aluminum alloy that is fully annealed to improve workability and tempered to provide strength and resistance suitable for marine applications.

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

Marine Grade Aluminum Square Bar 5052 5A02

Marine-grade aluminum square bars 5052 and 5A02 are two commonly used aluminum alloy materials in marine and corrosive environments, known for their excellent corrosion resistance and mechanical properties.

-

5052 O H112 Marine Grade Aluminum Hexagon Bar

The 5052 O H112 aluminum alloy hexagonal bar has excellent corrosion resistance, making it suitable for the manufacture of ship components.

-

5052 O H112 Marine Grade Aluminum Round Bars

5052 aluminum round bars have excellent formability and durability, making them widely used in the manufacturing of ship components.