5059 H111 Aluminum

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working. The H111 condition is a material state with relatively low strength and good ductility, making it suitable for many applications that do not require high strength.

The high magnesium content of 5059 aluminum alloy provides superior corrosion resistance in saltwater environments, making it particularly suitable for use in ships, marine facilities, and other applications exposed to water bodies.

The H111 condition is achieved through cold working and strain hardening, with the final hardness being lower than the strength requirements of the H11 condition. To achieve the H111 condition, the metal is strain-hardened to a strength below the maximum allowable hardness of the H11 specification (i.e., the maximum hardness is only 1/8 of the H11 specification).

5059 H111 Aluminum Mechanical Properties

| Property | 5059-H111 Aluminum |

| Elastic (Young's, Tensile) Modulus, GPa | 69 |

| Elongation at Break, % | 25 |

| Fatigue Strength, MPa | 170 |

| Poisson's Ratio | 0.33 |

| Shear Modulus, GPa | 26 |

| Shear Strength, MPa | 230 |

| Tensile Strength: Ultimate (UTS), MPa | 360 |

| Tensile Strength: Yield (Proof), MPa | 180 |

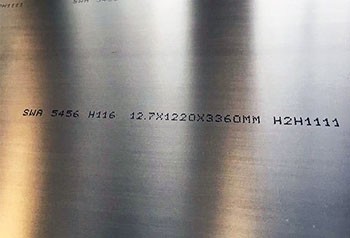

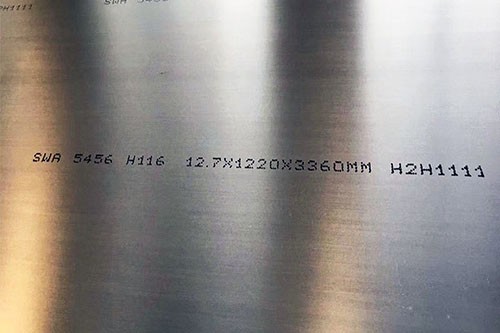

Chemical Composition of 5059 Aluminum H111 Alloy

| Grade | Max(%) | ||||||||

| Alloy 5059 | Si | Fe | Cu | Mn | Mn | Cr | Zn | Ti | Al |

| 0.45 | 0.5 | 0.25 | 0.6-1.2 | 5.0-6.0 | 0.25 | 0.40-0.9 | 0.2 | Remainder | |

5059 H111 Aluminum Properties

Ductility and Malleability

5059-H111 aluminum alloy has a higher elongation at fracture (25%) compared to other aluminum alloy conditions (such as T6 or H116), which means it can undergo more deformation without breaking during the stretching process. Its good ductility makes it especially suitable for applications requiring extensive forming, deep processing, or welding.

Corrosion Resistance

5059 series aluminum alloys are renowned for their excellent corrosion resistance, especially in marine and saltwater environments. Due to its high magnesium content, it provides good resistance to corrosion in seawater, salt spray, and other corrosive media, making it highly popular in marine structures, ships, and other applications requiring water exposure resistance.

Workability

5059 H111 aluminum alloy has good machinability, particularly in applications that require deep processing, welding, or forming. Due to its lower strength and higher ductility, it can withstand large deformations without cracking or breaking, making it suitable for complex machining processes.

Weldability

5059 H111 aluminum alloy has good weldability and is suitable for welding processes such as tungsten inert gas welding (TIG) and metal active gas welding (MAG). After welding, the alloy maintains its good corrosion resistance and strength.

5059 H111 Aluminum Applications

Shipbuilding

5059 H111 aluminum alloy is widely used in hull structures, ship components, and marine platforms, especially in applications exposed to saltwater environments, such as ship exteriors, decks, and internal structures.

Marine Equipment

5059 H111 aluminum alloy is suitable for making marine exploration equipment, buoys, subsea mining equipment, and other devices that frequently come into contact with seawater or saltwater.

Chemical and Seawater Treatment Equipment

5059 H111 aluminum alloy is used to make chemical reaction vessels, pipelines, heat exchangers, and other equipment operating in highly corrosive environments.

Other Structural Components with High Ductility Requirements

Due to its good ductility, 5059-H111 aluminum alloy is also suitable for applications that require extensive forming and welding.

The advantages of 5059-H111 aluminum alloy lie in its excellent corrosion resistance and good ductility, making it ideal for marine environments and high-corrosion applications. Due to its moderate strength and good machinability, it performs excellently in applications requiring welding and forming. However, for applications with higher demands for strength and fatigue resistance, 5059-H116 or other higher-strength aluminum alloys may be needed.

Tags: Marine Aluminum 5059