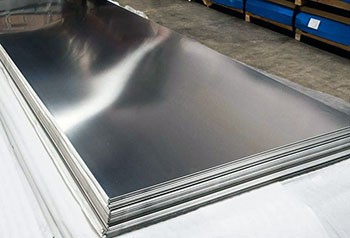

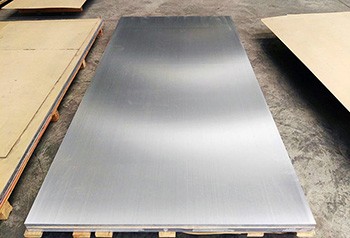

5059 H321 Aluminum

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment. This condition of 5059 aluminum alloy combines high strength with a certain level of corrosion resistance, making it highly suitable for applications that require high strength under load and have good fatigue performance.

5059-H321 Aluminum Alloy Characteristics

5059-H321 aluminum alloy undergoes a specific heat treatment process that gives the metal strong strength while simultaneously improving its corrosion resistance.

- Strain Hardening: The aluminum alloy is plastically deformed through mechanical processing (such as stretching or forging), which enhances its strength. This process causes a change in the metal's lattice structure, generating dislocations, and consequently increasing the material's strength.

- Stabilization Treatment: After strain hardening, the aluminum alloy also undergoes a stabilization treatment (such as low-temperature heat treatment) to reduce the internal stresses generated by strain hardening and to improve the metal's corrosion resistance.

5059 H321 Aluminum Mechanical Properties

| Property | 5059-H321 Aluminum |

| Elastic (Young's, Tensile) Modulus, GPa | 69 |

| Elongation at Break, % | 11 |

| Fatigue Strength, MPa | 240 |

| Poisson's Ratio | 0.33 |

| Shear Modulus, GPa | 26 |

| Shear Strength, MPa | 250 |

| Tensile Strength: Ultimate (UTS), MPa | 410 |

| Tensile Strength: Yield (Proof), MPa | 300 |

5059 H321 Aluminum Strength and Performance

The strength of 5059-H321 aluminum alloy is between the annealed (O state) and fully hardened (H38 state) conditions, typically reaching about a quarter of the strength of both the annealed and fully hardened states. This strength level allows 5059-H321 aluminum alloy to provide adequate strength while ensuring a certain level of ductility and formability in many applications.

- Tensile Strength and Yield Strength: Although the strength of 5059-H321 is lower than that of the fully hardened state, it is sufficient to handle moderate loads and has good workability when needed.

- Balanced Strength and Toughness: The 5059 aluminum alloy in this condition maintains a balance between strength and toughness, making it suitable for applications that require durability and certain fatigue performance.

5059 H321 Aluminum Corrosion Resistance

5059-H321 aluminum alloy, through heat treatment, possesses certain corrosion resistance, particularly in marine environments or other corrosive settings. Its corrosion resistance is improved in terms of intergranular corrosion and exfoliation corrosion, though it is slightly inferior to the H116 state in terms of overall corrosion resistance.

- Intergranular Corrosion Resistance: The H321 condition enables 5059 aluminum alloy to offer good resistance to intergranular corrosion in some highly corrosive environments, such as seawater or chemical media. While not as superior as the H116 state, its corrosion resistance is sufficient for general industrial requirements.

- Exfoliation Corrosion Resistance: 5059-H321 aluminum alloy, when exposed to salt fog or other corrosive media, can prevent the exfoliation of the surface corrosion film to some extent, thereby extending its service life.

5059 H321 Aluminum Applications

5059-H321 aluminum alloy, due to its unique strength, corrosion resistance, and workability, performs excellently in certain specific applications, especially in environments requiring high strength and good fatigue performance.

- Aerospace: 5059-H321 aluminum alloy is commonly used in aircraft fuselages, wings, and structural frames, especially in parts that need to resist stress corrosion cracking and have high fatigue strength requirements.

- Transportation: In high-load transportation vehicles (such as high-pressure vessels, heavy truck frames), 5059-H321 aluminum alloy is widely used due to its excellent fatigue resistance, which effectively prevents damage from long-term loading.

- High-Strength Structural Parts: The strength and fatigue performance of 5059-H321 make it an ideal choice for manufacturing structural components like bridges, crane structures, heavy machinery, and high-pressure pipelines.

5059 H321 Aluminum Welding and Workability

5059-H321 aluminum alloy has good weldability and workability, making it suitable for environments requiring complex processing and welding. Due to its moderate strength in the H321 condition, welding and machining are less likely to result in excessive cracking or deformation, allowing conventional aluminum welding methods to be used during manufacturing.

5059-H321 aluminum alloy, through strain hardening and stabilization treatment, achieves moderate strength and good corrosion resistance. It is suitable for applications that require high strength, fatigue resistance, and the ability to withstand certain corrosive environments, such as aerospace, transportation vehicles, and bridge structures. In these applications, 5059-H321 aluminum alloy offers sufficient performance advantages and good workability, making it an ideal choice for many high-strength structural components.

Tags: Marine Aluminum 5059