5059 Marine Grade Aluminum Plate Sheet

5059 aluminum plate is a 5-series aluminum-magnesium alloy material with moderate strength, good corrosion resistance, and weldability, widely used in multiple industrial fields.

5059 aluminum is a high-strength, corrosion-resistant alloy in the 5000 series, primarily composed of magnesium (5-6%) and manganese (0.6-1.2%). It is specifically designed for forging applications, not suitable for heat treatment but can be strengthened through strain hardening (such as cold rolling or stretching). It is widely used in marine, aerospace, and low-temperature environments, balancing lightweight properties with durability and weldability.

5059 aluminum plate is a high-strength marine-grade alloy in the 5000 series. Its main alloying element is magnesium, which, along with manganese, zinc, and zirconium, provides the alloy with excellent strength, durability, and corrosion resistance. This alloy is designated as 5059 by the Aluminum Association (AA) and is referred to as EN AW-5059 in European standards. It is primarily used for forged products, strengthened by strain hardening (cold working) rather than heat treatment.

The maritime industry has increasingly higher demands for the strength and speed of vessels, which has led to concerns that materials like 5083 may not meet these performance requirements. In this context, the emergence of 5059 aluminum alloy, which has a higher magnesium content, is significant. While increasing the magnesium content can greatly enhance the mechanical properties of the alloy, it also tends to reduce its corrosion resistance. Therefore, achieving both improved mechanical performance and excellent corrosion resistance is a key characteristic of 5059 aluminum.

5059 aluminum alloy combines the advantages of high magnesium and high zinc, overcoming the traditional shortcomings of high magnesium alloys in terms of corrosion resistance, while providing greater strength and stability, making it particularly suitable for modern shipbuilding demands.

The addition of zinc in 5059 effectively improves the corrosion performance of high magnesium aluminum alloys. Compared to 5083, 5059 has higher levels of aluminum, magnesium, and zinc. It also contains a relatively high amount of copper, which enhances the strength and hardness of the alloy. Additionally, the presence of chromium and manganese contributes to the corrosion resistance and improves oxidation resistance, making 5059 both strong and resistant to corrosion.

Beyond corrosion resistance, 5059 exhibits a very prominent feature: its flame retardancy. It maintains a certain level of strength and stability at high temperatures, reducing safety hazards related to fire.

Marine grade 5059 aluminum plate, specifically designed to withstand the harsh environments encountered in marine applications. These applications often expose materials to corrosive salt water, extreme weather conditions, and often to moisture.

The performance of 5059 alloy is better than that of 5083 alloy. However, due to its higher magnesium content, its pressure processing and forming capabilities are slightly inferior to those of 5083 alloy. Generally speaking, 5059 has better mechanical properties and corrosion resistance than 5083 marine grade aluminum and can be used as a replacement for 5083.

5059 Marine Grade Aluminum Plate Sheet Features

1. Corrosion resistance: 5059 alloy contains elements such as magnesium and chromium, which can enhance its corrosion resistance. This feature ensures longevity and durability even with prolonged exposure to salt water.

- 2. Strength and durability: Marine-grade aluminum has excellent strength and durability while resisting corrosion. This allows it to withstand the harsh conditions encountered in marine applications, including the effects of waves, wind and other environmental factors.

- 3. Light weight: Despite its high strength, aluminum is relatively lightweight compared to other metals such as steel. This property is advantageous in marine applications, where weight reduction is important for improved fuel efficiency and maneuverability.

- 4. Weldability: Aluminum alloys, including 5059, are generally highly weldable. This enables easy fabrication and repair, which is crucial for marine structures and ships.

- 5. Formability: Aluminum can be easily formed into a variety of shapes and sizes, allowing for flexibility in design and construction. This is advantageous for creating customized components and structures suitable for specific marine applications.

- 6. Low maintenance costs: The corrosion-resistant properties of marine-grade aluminum reduce the need for frequent maintenance and painting, thereby lowering maintenance costs throughout the life of the structure or container.

- 7. Environmental Sustainability: Aluminum is a recyclable material and therefore environmentally friendly. Its recyclability contributes to the sustainability of the marine industry by reducing the need for new raw materials and minimizing waste.

Overall, 5059 marine-grade aluminum plate’s combination of corrosion resistance, strength, lightweight properties and formability make it ideal for a variety of marine applications, including shipbuilding, offshore structures, marine components and marine equipment.

Specifications of 5059 Marine Aluminum Plate

| Alloy | 5059 |

| Temper | H131, H111, H116, H321 |

| Shape | Plate, Sheet, Tread Plate |

| Thickness(mm) | 3-50 |

| Width(mm) | 2000 or customized |

| Length(mm) | 6000/8000/9000/12000mm Or customized |

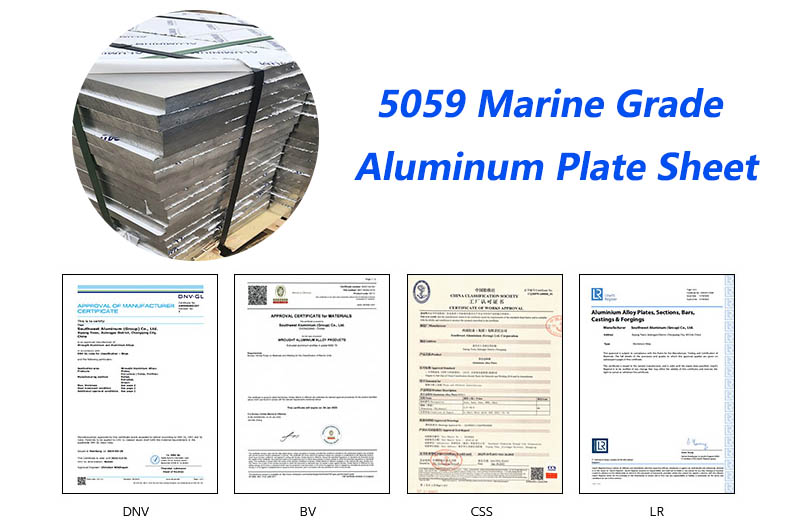

| Certification | ISO9001, CCS, DNV, ABS, LR, KR, BV |

| Application | Yachts, cruise ships, cargo ships, fishing boats, etc. |

Haomei Aluminum adopts a strict quality and environmental management system, and all marine grade aluminum plates have passed CCS, DNV, NK, CCS, ABS, BV, LR, KR certification.

5059 Aluminum Plate Temper Variations

| Temper | Description |

| 5059 O (Annealed) | 5059 aluminum plate in the O (annealed) state exhibits the best formability, making it particularly suitable for applications that require complex forming operations. Despite moderate strength, its excellent processing performance makes it widely used in processes requiring further processing. |

| 5059 H111/H116 | 5059 aluminum plate in H111 and H116 tempers, strengthened by strain hardening, provides higher tensile and yield strength. These tempers are particularly suitable for applications requiring high structural strength, commonly found in shipbuilding, marine structures, and other industries. |

| 5059 H321 | 5059 aluminum plate in the H321 temper, combining cold working and stabilization treatment, offers high strength while maintaining excellent corrosion resistance. This temper is suitable for use in high-strength structural components exposed to harsh environmental conditions, especially in marine and aerospace applications. |

5059 Aluminum Plate Corrosion Resistance

| Feature | Description |

| Excellent in marine environments | 5059 aluminum plate has excellent corrosion resistance in marine environments, effectively resisting corrosion from saltwater, humidity, and other harsh conditions. This makes it particularly suitable for applications in the marine and shipbuilding industries, such as hulls and offshore platforms, where it maintains stable performance even after prolonged exposure to seawater. |

| Passed stringent exfoliation and intergranular corrosion tests (e.g., GB/T 22639, GB/T 7998) | 5059 aluminum plate has undergone rigorous exfoliation and intergranular corrosion tests (such as GB/T 22639, GB/T 7998), ensuring its performance in harsh environments. These test standards verify that 5059 aluminum plate has extremely strong corrosion resistance, effectively preventing performance degradation due to corrosion, making it ideal for high-end structural and critical components that require high corrosion resistance. |

Mechanical properties of 5059 marine grade aluminum plate sheet

| Alloy | Temper | Thickness mm | Tensile Strength RmMPa | Specified non-proportional tensile strength Rp0.2 Mpa | Elongation% | |

| A50 mm | A | |||||

| 5059 | O | 3.00-50.00 | 330-380 | ≥160 | ≥24 | ≥24 |

| H111 | 3.00-50.00 | 330-380 | ≥160 | ≥24 | ≥24 | |

| H116 | 3.00-20.00 | ≥370 | ≥270 | ≥10 | ≥10 | |

| >20.00-50.00 | ≥360 | ≥260 | - | ≥10 | ||

| H321 | 3.00-20.00 | ≥370 | ≥270 | ≥10 | ≥10 | |

| 20.00-50.00 | ≥360 | ≥260 | - | ≥10 | ||

Advantages of 5059 Marine Aluminum Sheet

Using aluminum alloys as a ship structural material has several advantages that make it a popular choice, especially for small and medium-sized vessels such as hydrofoils, hovercrafts and small warships.

- 1. Low density: Compared with traditional shipbuilding materials such as steel, aluminum alloys have a lower density. This means that using aluminum can reduce the weight of the ship's structure, thereby reducing overall weight and improving buoyancy. Lighter ships require less fuel to operate, resulting in greater fuel efficiency and lower operating costs.

- 2. Non-magnetic: Unlike steel, 5059 aluminum alloy is non-magnetic. This property is advantageous in naval applications where magnetic interference can affect sensitive equipment such as compasses and navigation systems. By using aluminum, ships can minimize magnetic interference and improve navigation accuracy.

- 3. Good low-temperature properties: Aluminum alloy can maintain its mechanical properties even at low temperatures, making it suitable for use in cold climates or ice water. This ensures that the ship’s structural integrity remains intact even in challenging environmental conditions, improving safety and reliability.

- 4. Reduce weight and increase load capacity: By using aluminum alloys, shipbuilders can design lighter yet stronger structures that increase payload capacity without compromising safety or performance. The reduced ship weight also helps improve stability, maneuverability and speed, providing a more agile and efficient vessel.

- 5. Excellent corrosion resistance: The marine environment, especially seawater, exposes ships to corrosive elements that can degrade metal structures over time. Aluminum alloys such as 5059 offer excellent corrosion resistance, protecting hulls and other components from rust and corrosion. This extends the life of the vessel and reduces the need for frequent maintenance and repairs.

- 6. High tensile strength: 5059 aluminum alloy belongs to the Al-Mg series and has high tensile strength comparable to some low carbon steels. This ensures structural integrity and durability even under heavy loads and harsh marine conditions.

- 7. Good welding performance: Aluminum alloy is highly weldable and can efficiently build and repair ship structures. Good welding performance ensures a strong and reliable joint, contributing to the overall integrity of the container.

Aluminum alloy 5059 is commonly used in a variety of marine projects, from small recreational boats to large cruise ships. Their versatility, durability and corrosion resistance make them suitable for a wide range of applications in the maritime industry.

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility. These advantages make it the preferred material for building modern ships, especially small ships and special ships.

Chemical composition of 5059 marine grade aluminum plate sheet

| Alloy | 5059 |

| Si | ≤0.45 |

| Fe | ≤0.5 |

| Cu | ≤0.25 |

| Mn | 0.6-1.2 |

| Mg | 5.0-6.0 |

| Cr | ≤0.25 |

| Zn | 0.4-0.9 |

| Ti | ≤0.2 |

| Zr | 0.05-0.25 |

| Standard | EN573 ASTM B928 |

5059 Marine Grade Aluminum Plate Sheet product details

5059 Aluminum Plate Comparison with Similar Alloys

| Comparison Feature | 5059 Aluminum Plate | 5083 Aluminum Plate |

| Strength | 5059 aluminum plate has a higher tensile strength, performing excellently in applications requiring high strength, especially in environments that need to withstand heavy loads and pressure. Compared to 5083, 5059 aluminum plate offers superior strength, providing stronger support under harsh working conditions. | While 5083 aluminum plate has high strength, it is slightly less tensile compared to 5059. Therefore, in applications where strict strength requirements are essential, 5059 aluminum plate has the advantage. |

| Formability | Due to the higher alloy content, 5059 aluminum plate is slightly less formable than 5083 aluminum plate. More attention is required during processing to ensure the material can be effectively shaped, especially in complex forming operations where it may be less convenient. | With a relatively lower alloy content, 5083 aluminum plate has better formability, making it particularly suitable for applications requiring complex forming or deep processing. Its excellent processing performance makes it more convenient to manufacture and suitable for producing a variety of high-demand structural components. |

Applications of Haomei Aluminum 5059 marine grade aluminum plate sheet

Marine grade aluminum alloy 5059 sheet is widely used throughout the marine industry due to its superior properties tailored to the marine environment.

- Hull: 5059 One of the main applications of aluminum in the marine industry is in the construction of ship hulls. The alloy’s corrosion-resistant properties ensure long service life even in saltwater environments, while its strength-to-weight ratio helps optimize the vessel’s performance and fuel efficiency.

- Ship superstructure: Ship superstructures, including cabins, decks and bridge structures, are usually made of 5059 aluminum plates due to their lightweight and corrosion-resistant properties. These components require materials that can withstand harsh marine conditions without compromising structural integrity.

- Marine platforms and walkways: Platforms, ramps and walkways on ships, offshore rigs and docks benefit from the durability and corrosion resistance of 5059 aluminum plate. These structures require materials that can withstand heavy loads and sustained exposure to salt water without corroding or degrading.

- Marine equipment and components: A variety of marine equipment and components, such as fuel tanks, piping systems, and structural supports, are manufactured from 5059 aluminum alloy. Its weldability and machinability make it suitable for manufacturing complex components critical to the functionality and safety of ships and structures.

- Offshore structures: Offshore platforms, buoys and other offshore structures require materials that can withstand harsh marine environments, including corrosive seawater, strong winds and unpredictable weather conditions. The corrosion resistance and strength of 5059 aluminum make it the first choice for this type of application.

- Fishing boats and equipment: Fishing boats and equipment, including trawlers, fishing boats and equipment racks, often feature marine-grade aluminum panels because of their lightweight and corrosion-resistant properties. Additionally, the alloy is easy to fabricate, allowing fishing equipment to be customized to meet specific requirements.

- Recreational Boats: Recreational boats, yachts and personal watercraft benefit from the use of 5059 aluminum in a variety of structural components such as hulls, decks and accessories. The alloy's combination of strength, corrosion resistance and formability helps improve the overall performance and longevity of recreational boats.

- Pier and pier construction: Aluminum panels are also used in the construction of piers, piers and waterfront structures. These structures require materials that can withstand saltwater and freshwater environments while maintaining structural stability and safety.

The versatility, durability and corrosion resistance of marine-grade aluminum alloy 5059 make it indispensable in a variety of marine applications, helping to enable safer, more efficient and longer-lasting marine structures and vessels.

5059 Aluminum Plate Manufacturing and Processing

- Welding: Compatible with TIG, MIG, and resistance welding, making it ideal for shipbuilding assemblies.

- Machining: Easily cut, drilled, or bent using standard tools.

- Surface treatment: Anodizing or coating can enhance corrosion resistance.

- Manufacturing processes: Includes casting, hot/cold rolling, annealing, and stress relief.

Haomei Aluminum is an aluminum plate manufacturer specializing in the production of marine aluminum plates, providing 5059 marine aluminum plates, 5059 medium-thick aluminum plates, 5059 extra-wide aluminum plates, 5059 alloy aluminum plates, etc. The product not only has good shape, smooth and delicate surface, and small thickness tolerance. The product models are complete and can be customized according to customer needs. The delivery is fast, the output is large, and the after-sales service is guaranteed.

Recommended for you

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

Other content readers are interested in

-

5059 5086 Marine Grade Aluminum Bars

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

More content of interest to readers

5059-H116 Aluminum vs. 5059-H321 Aluminum 5059 Aluminum vs. 5083 Aluminum 5059-H111 Aluminum vs. 5059-H116 Aluminum 5083 vs. 5059: Aluminum Alloy Selection in Shipbuilding

You might be interested in: Marine Aluminum 5059