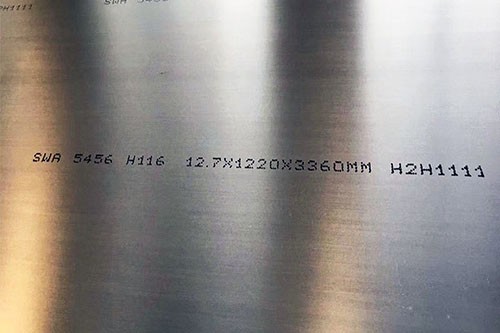

5083 H116 Aluminum Plate

5083-H116 is a non-heat-treatable 5xxx series aluminum alloy with a magnesium content of 4.0-4.9 wt% and manganese content of 0.4-1.0 wt%. It is strain-hardened, providing stable tensile performance and enhanced corrosion resistance in marine environments.

In the H116 temper, 5083 aluminum plate retains excellent formability, weldability, and seawater corrosion resistance, making it an ideal choice for shipbuilding, pressure vessels, and transportation structures.

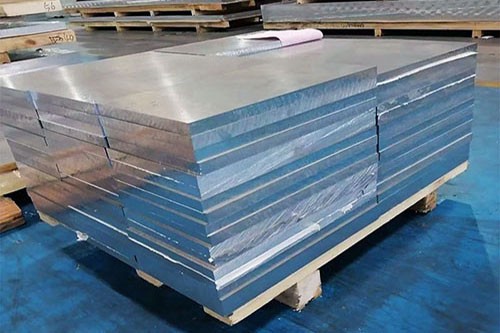

As a professional aluminum plate manufacturer, our company supplies 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV). With outstanding corrosion resistance, weldability, and medium strength, they are widely used in ship decks, hull outer plates, and LNG storage tanks. We support customized thickness from 0.15–600 mm and width up to 2.5 m for ultra-wide plates, offering short lead times and international-quality standards to facilitate ship lightweighting and efficient industrial manufacturing.

5083 H116 Aluminum Plate Chemical Composition

The chemical composition of 5083-H116 alloy balances strength and corrosion resistance:

- Magnesium (Mg): 4.0–4.9 wt%

- Manganese (Mn): 0.4–1.0 wt%

- Chromium (Cr): 0.05 – 0.25 wt%

- Silicon (Si): ≤ 0.4 wt%

- Iron (Fe): ≤ 0.4 wt%

- Zinc (Zn): ≤ 0.25 wt%

- Titanium (Ti): ≤ 0.15 wt%

- Others (each): ≤ 0.05 wt%; Total others: ≤ 0.15 wt%

- Aluminum (Al): Remainder

5083 H116 Temper and Delivery Condition

In the H116 temper, the product is strain-hardened during the final manufacturing step to achieve the specified tensile strength and tested for accelerated intergranular corrosion and exfoliation corrosion to ensure stable performance at temperatures up to 66°C (150°F).

Unlike heat-treatable alloys, achieving H116 temper requires mechanical processing and, if necessary, controlled low-temperature treatment (rather than full solution heat treatment) to meet the required corrosion resistance.

5083 H116 Aluminum Plate Mechanical Properties

- Yield Strength (0.2% offset): ≥ 215 MPa

- Ultimate Tensile Strength: ≈ 305 MPa

- Elongation at Break: ≥ 10% (based on 50 mm gauge length)

- Brinell Hardness: ≈ 85 HBW

These values represent the highest strength among non-heat-treatable aluminum alloys, reflecting an excellent combination of strength and ductility.

High hardness is achieved without sacrificing formability, allowing for complex sheet forming and bending operations.

5083 H116 Aluminum Plate Physical Properties

- Density: ≈ 2.66 g/cm³

- Melting Range: 570 – 645 °C

- Thermal Expansion Coefficient: 24.2 µm/m·K (20–100 °C)

- Modulus of Elasticity: ≈ 70 GPa

- Electrical Conductivity: ≈ 29% IACS

These physical constants ensure that 5083-H116 maintains dimensional stability under thermal cycling and provides good heat dissipation in structural applications.

5083 H116 Aluminum Plate Advantages

| Advantage Category | Description |

| Corrosion Resistance | 5083 H116 Aluminum features excellent corrosion resistance, forming a dense and stable natural oxide film in marine environments and saline atmospheres. This protective oxide layer effectively prevents intrusion by corrosive agents like chloride ions, significantly extending the material’s service life. After anodizing, its surface hardness and durability are further enhanced, improving both corrosion resistance and decorative effects. It is ideal for hull structures and marine platforms exposed to seawater or humid environments for extended periods. |

| Weldability | 5083 H116 Aluminum offers excellent weldability and is compatible with various welding techniques including TIG and MIG. During welding, the material exhibits good stability in the heat-affected zone, and the welded joints maintain high strength and toughness, without significant cracking or strength reduction. This structural integrity post-welding makes it a preferred material for ship structures such as hulls, decks, and bulkheads, ensuring outstanding structural reliability even under complex sea conditions. |

| Formability | 5083 H116 Aluminum demonstrates excellent formability during both hot and cold processing. Whether bending, rolling, stamping, or stretching, the alloy maintains good plasticity and ductility, with low risk of cracking or instability. This superior formability makes it especially suitable for manufacturing large-size, complex-shaped, or high-precision ship components, improving manufacturing efficiency and economic value while ensuring structural accuracy. |

| Low Temperature Performance | 5083 H116 Aluminum maintains high toughness and good mechanical properties even in low-temperature environments, without brittle fracture, offering enhanced structural safety. Therefore, it is particularly suitable for applications such as LNG storage tanks, refrigerated ships, and polar equipment, which require excellent low-temperature performance. Its reliable strength and ductility in extreme cold make it one of the key materials in cryogenic engineering. |

5083 H116 Aluminum Plate Applications

These comprehensive properties make 5083-H116 aluminum plate a preferred choice for the following applications:

- Shipbuilding: hulls, decks, superstructures

- Pressure Vessels: LNG storage tanks, chemical tanks, and oil tanks

- Transportation: truck bodies, trailers, rail vehicles

- Offshore Structures: drilling platforms, platforms, pipelines

- Cryogenic Equipment: storage tanks operating down to -200 °C

| Application Field | Description |

| Marine Engineering | 5083 H116 aluminum plate features excellent corrosion resistance, especially outstanding in seawater and humid environments, making it widely used in marine engineering. Its lightweight characteristics enhance fuel efficiency in hull structures, while its high strength and good weldability ensure long-term reliability of hulls and structural components. 5083 H116 is particularly suitable for manufacturing various hulls, decks, hatch covers, and superstructures, meeting the performance requirements of high-speed vessels, workboats, fishing boats, and coast guard ships. |

| Transportation | In the transportation field, 5083 H116 aluminum plate is an ideal material for rail vehicles, armored transporters, and heavy truck bodies due to its lightweight and high-strength properties. Its excellent impact resistance and energy absorption capabilities significantly enhance vehicle safety and load capacity; compared to traditional steel, its lighter weight helps reduce energy consumption and improve transportation efficiency. Additionally, 5083 H116 offers good formability and weldability, facilitating the fabrication of complex structures. |

| Pressure Vessels | 5083 H116 aluminum plate, with its high strength-to-weight ratio, can withstand certain internal pressures while remaining lightweight, making it an ideal material for manufacturing LNG storage tanks, offshore platform liquid storage tanks, and mobile pressure vessels. Its excellent corrosion resistance is especially crucial for pressure vessels exposed to corrosive media over long periods, effectively extending equipment life and reducing maintenance costs. Furthermore, its stable weldability ensures the safety and sealing of pressure vessel joints. |

| Industrial Structures | 5083 H116 aluminum plate is widely used in various industrial structures, particularly excelling in offshore platforms, chemical processing equipment, and pipeline systems. Its high strength, corrosion resistance, and good machinability enable it to maintain structural stability under high salt spray, high humidity, and heavy load conditions. Whether used in load-bearing beams, platform railings, or reaction vessels and pipelines exposed to highly corrosive media, 5083 H116 provides reliable strength and durability support. |

| Aerospace | In the aerospace field, 5083 H116 aluminum plate is widely used in the manufacturing of aircraft fuel tanks, fuel pipelines, and some secondary structural components. Its corrosion resistance is crucial when storing and transporting aviation fuel and other highly corrosive media; meanwhile, its good weldability and formability allow adaptation to various structural needs. The lightweight property of 5083 H116 also contributes to overall weight reduction, enhancing aircraft fuel efficiency and load capacity, making it an indispensable material in many civil and military aerospace systems. |

| Other Applications | 5083 H116 aluminum plate is also widely used in various other structures and equipment, such as TV towers, armored parts, and hardware products. In these applications, its high strength and impact resistance ensure structural safety, while its excellent machinability and weldability make it well-suited for complex designs and manufacturing. Especially in armor and security fields, 5083 H116 is a preferred material for lightweight protective equipment due to its outstanding toughness and ballistic resistance. |

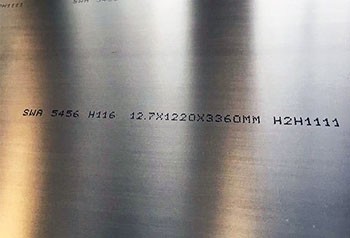

5083 H116 Aluminum Plate Standards and Specifications

5083-H116 plates are manufactured in accordance with the following major international standards to ensure consistent quality:

- ASTM B209/B209M – Aluminum and Aluminum-Alloy Sheet and Plate

- EN 573-3 / EN 485-2 – Chemical Composition and Mechanical Properties of Wrought Alloys

- DIN 3.3547 – German standard for AlMg4.5Mn0.7 alloy

- ISO 6361 – Wrought Aluminum and Aluminum Alloys—Sheet, Strip and Plate

Haomei 5083 H116 aluminum plate complies with ASTM B209, ASME SB209, and EN 485-2 standards, ensuring quality for marine and industrial applications.

Certified by the American Bureau of Shipping (ABS) and Det Norske Veritas (DNV), meeting shipbuilding standards.

Comparison Between 5083 H116 and Other Tempers

H116 vs. H321:

- H116: Optimized for exfoliation corrosion resistance, magnesium content ≥4%, more suitable for marine environments.

- H321: Stable post-hardening properties, higher hardness and thermal stability, suitable for specialized applications.

5083 H116 Aluminum Processing and Welding Performance

It is easy to weld using MIG, TIG, and arc welding processes, forming strong and ductile joints without significant deterioration in mechanical properties.

- Weldability: Excellent arc welding performance, suitable for complex welded structures

- Cold Workability: Good plasticity, suitable for stamping, bending, and other processes

- Surface Treatment: Can be anodized to enhance corrosion resistance and aesthetics

5083 H116 Aluminum Plate Processing Considerations

- Cannot be strengthened by heat treatment, strength must be improved through cold working

- Machinability is average; specialized tools are recommended to reduce wear

- Heat input should be controlled during welding to avoid reducing corrosion resistance

Marine aluminum products you may be interested in

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5059 Marine Grade Aluminum Plate Sheet

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5383 Marine Grade Aluminum Plate Sheet

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.