5083 H321 Aluminum Plate

5083 H321 is a strain-hardened and stabilized variant of the 5083 aluminum alloy, renowned for its excellent corrosion resistance (especially in marine environments) and high strength-to-weight ratio. The H321 temper indicates that the material has undergone strain hardening and stabilization treatment to prevent sensitization (precipitation of magnesium at grain boundaries), thereby enhancing its durability under cyclic loading and corrosive conditions. Typical applications include shipbuilding, offshore structures, pressure vessels, and cryogenic tanks, where both strength and corrosion resistance are critical.

5083 H321 is an aluminum-magnesium alloy from the 5xxx series, known for its excellent corrosion resistance and weldability.

With its high strength, excellent corrosion resistance, and weldability, 5083 H321 aluminum plate is a preferred material in shipbuilding, transportation, and pressure vessel applications. The cold working hardening and stabilization treatment (H321 temper) ensures the stability of its performance. Combined with the capability of producing ultra-wide and ultra-thick specifications, it meets the high standards required for complex structural components.

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications. Our aluminum plates comply with ASTM B928 standards, offering excellent seawater corrosion resistance, high tensile strength, and superior weldability. We provide customized cutting services for sizes and thicknesses, with strict quality control. For bulk orders, please request a quote to enjoy factory pricing, fast delivery, and technical support.

5083 H321 Aluminum Plate Chemical Composition

5083 aluminum alloy primarily uses magnesium as the alloying element, with small amounts of manganese and chromium to enhance strength and corrosion resistance. Typical composition ranges are as follows:

- Magnesium (Mg): 4.0 – 4.9%

- Manganese (Mn): 0.4 – 1.0%

- Chromium (Cr): 0.05 – 0.25%

- Iron (Fe): ≤ 0.4%

- Silicon (Si): ≤ 0.4%

- Copper (Cu): ≤ 0.1%

- Zinc (Zn): ≤ 0.25%

- Others (each): ≤ 0.05%; Total: ≤ 0.15%

- Aluminum (Al): Remainder

These alloying elements give the material high strength, excellent weldability, and outstanding resistance to seawater corrosion.

5083 H321 Aluminum Plate Mechanical Properties

In the H321 temper, 5083 aluminum exhibits strength and ductility suitable for structural applications:

- Tensile Strength: ≈ 275 MPa (40 ksi)

- Yield Strength (0.2% offset): ≈ 125 MPa (18 ksi)

- Elongation at Break: ≥ 12%

Other mechanical characteristics include Brinell hardness of approximately 75–85 HB. These properties make 5083-H321 aluminum stronger than pure aluminum while still maintaining good formability.

5083 H321 Aluminum Plate Physical Properties

- Density: 2.66 g/cm³ (lightweight).

- Melting Range: 570–640°C.

- Thermal Conductivity: 117 W/m·K.

- Electrical Conductivity: approx. 29% IACS.

5083 Aluminum Plate Temper Designation H321

- H3x: Strain hardened only (no heat treatment)

- H32: Strain hardened and stabilized ("2" indicates stabilization through low-temperature annealing to minimize sensitization)

- H321: Similar to H32, but specifically tailored for sensitization-prone alloys (e.g., 5052, 5083), ensuring any initial grain boundary precipitates are redissolved.

The stabilization step (typically at ~150°C) relieves internal stress without significant softening, thus preventing intergranular corrosion during welding or high-temperature usage.

| Temper Code | Classification | Description |

| H3 | Temper Type | Strain hardened and stabilized: After cold working (such as rolling), the material undergoes low-temperature stabilization heat treatment to eliminate residual stress and enhance corrosion resistance while retaining part of the cold-working strength. Suitable for applications requiring dimensional stability and corrosion resistance. |

| 2 | Degree of Hardening | Medium strain hardening, i.e., the material has about 1/4 hardness (close to H32), with mechanical properties higher than the annealed temper (O) but lower than the fully hardened temper (e.g., H38). |

| 1 | Stabilization Parameter Details | Indicates that under the H321 temper, the stabilization process parameters vary slightly but belong to the same series of treatments. For example, variations in heat treatment time and temperature are made to suit different batches or specific application needs, ensuring consistency and reliability of material performance. |

This stabilization treatment ensures dimensional stability under moderate thermal exposure (up to approximately 150°C), thereby reducing residual stress generated during manufacturing.

5083 H321 Aluminum Plate Core Characteristics

| Characteristic | Description |

| Corrosion Resistance | The 5083 H321 aluminum plate performs excellently in marine environments and industrial atmospheres, making it particularly suitable for scenarios involving contact with liquids or gases, offering superior corrosion protection. |

| Weldability | The 5083 H321 aluminum plate has good weldability and is suitable for arc welding, gas welding, and other welding processes. The welded joints exhibit high strength, making it especially suitable for welded structural components. |

| Workability | The 5083 H321 aluminum plate has good cold formability, though its machinability is average. It is recommended to use specialized tools for improved processing performance. |

| Surface Treatment | The 5083 H321 aluminum plate can undergo anodizing to enhance aesthetics and corrosion resistance, thereby improving service life and surface quality. |

5083 H321 Aluminum Corrosion Resistance

Corrosion Resistance: Performs exceptionally well in marine/chemical environments; thanks to the stabilization treatment, it resists Stress Corrosion Cracking (SCC).

5083-H321 is highly regarded for its outstanding corrosion resistance:

- Seawater and Marine Atmosphere: Minimal pitting even under chloride exposure.

- Industrial Environments: Good resistance to both general and localized corrosion in various chemical conditions.

- Low Temperatures: Maintains toughness and resists stress corrosion cracking even down to liquid nitrogen temperatures.

This makes it a preferred alloy for hulls, offshore platforms, and LNG storage.

5083 H321 Aluminum Weldability and Manufacturability

- Weldability: Excellent weldability using MIG, TIG, and resistance welding processes. Weld joints retain high strength and corrosion resistance, though localized softening (down to H111 level) may occur near the fusion zone.

- Formability: Good cold forming characteristics; with sufficient strain hardening margin, it can undergo rolling, stamping, and bending processes.

- Machinability: Good machinability; carbide tools and optimized feed/speed rates can achieve good surface finish without excessive tool wear.

5083 H321 Aluminum Plate Applications

Common applications of 5083-H321 aluminum plate include:

- Shipbuilding: Hulls, decks, marine platforms, superstructures, and decks of naval vessels, yachts, and ferries.

- Offshore Structures: Platforms, risers, and pipelines in oil and gas extraction.

- Pressure Vessels and Storage Tanks: For storing liquefied natural gas, cryogenic tanks, refrigerants, and high-pressure gases.

- Rail and Trucks: Lightweight body panels for tankers, truck trailers, and storage tanks.

- Structural Components: Bridges, architectural panels, and cryogenic equipment.

- Military: Armored vehicles and amphibious vessels.

- Construction: Bridges and building panels.

| Application | Description |

| Shipbuilding Industry | 5083 H321 aluminum plate is widely used in structural components such as hull decks, side panels, and engine bases, especially where CCS/ABS classification certification is required. |

| Transportation | 5083 H321 aluminum plate is used in light rail vehicles, tank car bodies/tanks, bus skins, automobile fuel tanks, and air reservoirs, providing excellent strength and corrosion resistance to meet various transportation needs. |

| Pressure Vessels | 5083 H321 aluminum plate is suitable for LNG tanks, refrigerated containers, and liquid tankers, offering good fire resistance and strength for demanding environments. |

| Other Fields | 5083 H321 aluminum plate can also be used in TV towers, missile components, architectural decorative parts, and precision machined parts, demonstrating excellent machinability and corrosion resistance. |

5083 H321 Aluminum Plate Industry Standards and Specifications

5083-H321 plates comply with multiple international standards, such as:

- ASTM B209: Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- EN 485-2 / EN 573-3: European standards for aluminum alloys and tempers

- ABS, DNV-GL: Classification society certifications for shipbuilding materials

Advantages of 5083 H321 Aluminum Plate

- High strength-to-weight ratio: Ideal for weight-sensitive designs.

- Weldability: Compatible with TIG/MIG welding using 5356 or 5183 filler rods.

- Formability: Moderate bendability in H321 temper; annealed (O temper) state allows for complex shapes.

- Durability: Excellent performance in harsh and salt-laden environments.

Limitations of 5083 H321 Aluminum

- Non-heat-treatable: Strength is solely derived from strain hardening.

- Temperature limitation: Avoid prolonged use above 65°C (150°F).

- Lower strength than 6xxx/7xxx series: Not suitable for ultra-high-stress applications.

Comparable Alloys to 5083 H321 Aluminum

- 5086-H32: Slightly lower magnesium content; similar applications.

- 5052-H32: Lower strength but better formability.

- 6061-T6: Heat-treatable with higher strength, but inferior corrosion resistance.

| Comparable Alloy | Comparison Details |

| 5086-H32 | 5083 H321 aluminum alloy is similar in performance to 5086-H32, as both belong to the high-magnesium series of marine-grade aluminum alloys and exhibit excellent resistance to seawater corrosion along with medium to high strength. In comparison, 5083 H321 contains slightly more magnesium, typically ranging from 4.0% to 4.9%, while 5086-H32 contains around 3.5% to 4.5%, giving 5083 H321 superior strength and stress-corrosion resistance. Both are commonly used in shipbuilding, marine structures, and armored vehicles, but when higher strength and more stable corrosion resistance are required, 5083 H321 is more advantageous. |

| 5052-H32 | 5083 H321 aluminum alloy significantly outperforms 5052-H32 in terms of strength, making it suitable for applications requiring higher load-bearing capacity and more demanding environments. While 5052-H32 has good formability and weldability and is widely used in moderate strength applications such as vehicle body panels, fuel tanks, and kitchen equipment, its tensile and yield strength are both lower than those of 5083 H321. Therefore, 5083 H321 is better suited for heavy-load structures and highly corrosive environments, especially in marine engineering and ship hull construction where corrosion resistance and strength are critically important. |

| 6061-T6 | Although 5083 H321 aluminum alloy cannot be strengthened through heat treatment, it exhibits significantly better corrosion resistance than the heat-treatable 6061-T6 alloy. 6061-T6 features higher strength and excellent machinability, making it widely used in aerospace, structural components, and industrial machinery. However, it performs poorly in seawater or highly corrosive environments. In contrast, 5083 H321 is a more reliable choice for marine engineering, shipbuilding, and chemical equipment due to its exceptional corrosion resistance. Especially in high-humidity, high-salt environments, 5083 H321 offers superior service life and stability compared to 6061-T6. |

Production Process and Quality Control of 5083 H321 Aluminum Plate

- Rolling Process: Utilizes homogenized heat treatment and controlled rolling techniques to ensure low internal stress, distortion-free cutting, and production of extra-wide (up to 2650mm) and extra-thick (up to 500mm) plates.

- Surface Quality: Free from oil stains, wavy patterns, scratches, and roll marks, with neat trimmed edges.

- Microalloying Improvement: Addition of trace Be (beryllium) reduces ingot cracking tendency and enhances rolled plate surface quality.

5083-H321 aluminum plate is an ideal choice for shipbuilding, transportation, and structural applications requiring a combination of strength, weldability, and corrosion resistance. Its stability in the H321 temper ensures reliability under dynamic and thermal conditions, making it a fundamental material for heavy-duty engineering.

Marine aluminum products you may be interested in

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5059 Marine Grade Aluminum Plate Sheet

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5383 Marine Grade Aluminum Plate Sheet

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

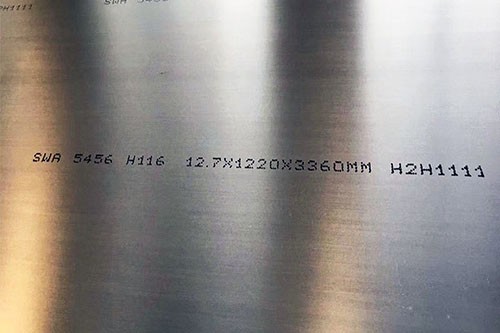

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.