5083 Marine Grade Aluminum Plate Sheet

In modern shipbuilding, especially in the construction of high-speed vessels, lower-density aluminum alloy structures are often used to achieve lightweight designs and improve vessel speed. 5083 aluminum plate has high strength and excellent corrosion resistance, making it a commonly used aluminum plate suitable for harsh marine environments.

5083 marine aluminum plates are mainly used in the H116, H321, and H112 tempers. Using aluminum plates for ship construction not only significantly reduces weight but also allows vessels made from aluminum plates to achieve faster speeds under the same power conditions.

Characteristics of 5083 Marine Aluminum Plates

5083 aluminum alloy is an aluminum alloy with excellent performance, widely used in modern shipbuilding, particularly in the construction of high-speed vessels.

- 1. High Strength: 5083 aluminum alloy has good strength characteristics, making it perform well under dynamic loads, suitable for structural components of high-speed vessels, such as decks and hull outer plates.

- 2. Excellent Corrosion Resistance: 5083 aluminum alloy is particularly resistant to seawater corrosion, effectively resisting the effects of saltwater and humidity in marine environments. This characteristic makes 5083 aluminum plates especially suitable for shipbuilding in marine and coastal areas, extending the lifespan of vessels and reducing maintenance costs.

- 3. Lightweight: Compared to traditional steel materials, 5083 aluminum alloy has a lower density, effectively reducing the overall weight of the vessel. This lightweight design not only improves the vessel's speed but also achieves better fuel efficiency under the same power conditions.

- 4. Good Weldability: 5083 aluminum plates maintain their mechanical properties during the welding process, making them suitable for various welding techniques.

5083 Marine Grade Aluminum Plate Sheet Specifications

- Alloy: 5083

- Standard Size: 1220mm X 2440mm

- Thickness: 0.02mm-100mm

- Width: 1000mm, 1219mm, 1220mm, 1500mm

- Length: 1-12m or as Required

- Specification: 4′x 8′, 5′ x 10′, etc.

- Tolerance: ±1%

- Free Sample: Send Inquiry to Get Free Sample for Evaluation

- Surface: Mill, Bright, Polished, Hair Line, Brush, Sand Blas

- Transport Package: Standard Seaworthy Package

- Standard: ASTM AISI JIS DIN GB

- Processing Service: Bending, Decoiling, Welding, Punching, Cutting

Heat Treatment States of 5083 Marine Aluminum

5083 aluminum alloy is commonly used in H116, H321, and H112 tempers, with H116 and H321 states being specially treated to enhance their stress corrosion resistance, making them suitable for use in harsh marine environments.

- The 5083 H116 and H321 states of aluminum alloy are suitable for load-bearing and critical structural components due to their high strength and superior corrosion resistance.

- The 5083 H112 state of aluminum alloy is more suitable for components that do not need to bear significant stress.

Below is a detailed comparison table of the different heat treatment states of 5083 marine aluminum alloy:

| Heat Treatment State | Heat Treatment Method | Strength Characteristics | Corrosion Resistance | Applications |

| 5083 H116 | Heat Treatment and Cold Working | Good tensile strength | Excellent stress corrosion resistance, suitable for harsh marine environments | Hull, decks, and high-strength durable structural components |

| 5083 H321 | Heat Treatment at Higher Temperatures | Good tensile strength, suitable for bearing high loads | Good corrosion resistance, suitable for high-temperature and marine environments | Load-bearing parts of vessels, such as frames and support structures |

| 5083 H112 | Simple Heat Treatment | Relatively lower strength requirements | General corrosion resistance, performs poorly in extreme environments | Non-critical vessel components, such as interiors and non-load-bearing outer shell components |

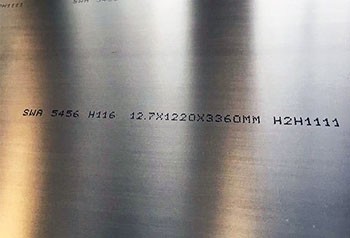

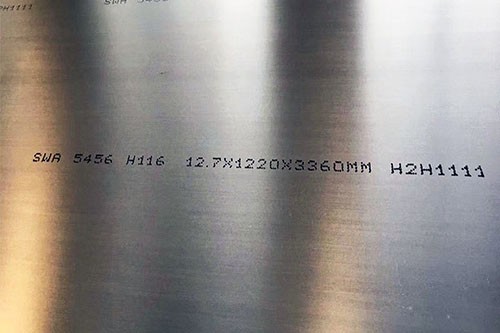

5083 H116 Marine Aluminum

Heat Treatment and Processing: The H116 state is obtained through a combination of heat treatment and cold processing. This process enhances the mechanical properties and corrosion resistance of the aluminum alloy.

Characteristics of 5083 H116 Aluminum

- Strength: It has good tensile strength and yield strength, usually exceeding 310 MPa.

- Corrosion Resistance: Special treatment enhances its stress corrosion resistance, making it suitable for long-term use in harsh marine environments.

5083 H116 aluminum is mainly used for structural components of vessels, such as hulls, decks, and other parts requiring high strength and durability.

5083 H321 Marine Aluminum

Heat Treatment: The H321 state undergoes heat treatment at higher temperatures, making it suitable for bearing greater stress.

Characteristics of 5083 H321 Aluminum

- Strength: It also has good tensile strength, suitable for bearing higher loads.

- Corrosion Resistance: It exhibits good corrosion resistance, especially in high-temperature and marine environments.

5083 H321 aluminum is typically used for load-bearing parts of vessels, such as frames, supporting structures, and other critical structural components.

5083 H112 Marine Aluminum

Heat Treatment: The H112 state undergoes simple heat treatment, resulting in a relatively lower strengthening effect.

Characteristics of 5083 H112 Aluminum

- Strength: It has relatively low strength requirements, suitable for parts that do not bear high stress.

- Corrosion Resistance: It has general corrosion resistance, but performs worse than H116 and H321 in extreme environments.

5083 H112 aluminum is usually used for non-critical parts of vessels, such as interiors and non-load-bearing outer shell components.

5083 Marine Grade Aluminum Plate Sheet Chemical Composition

| Alloy | 5083 |

| Si | ≦0.4 |

| Fe | ≦0.4 |

| Cu | ≦0.1 |

| Mn | 0.40-1.00 |

| Mg | 4.00-4.90 |

| Cr | 0.05-0.25 |

| Zn | ≦0.25 |

| Ti | ≦0.15 |

| Zr | - |

| Unit | Wt% |

5083 Marine Grade Aluminum Plate Sheet Mechanical properties

| Alloy | 5083 | |||

| Temper | O/H111/H112 | H116 | H321 | |

| Rm(Mpa) | Tensile strength | ≥275 | ≥305 | 305-385 |

| Rp0.2(MPa) | Yield strength | ≥125 | ≥215 | 215-295 |

| Elongation | A(%) | ≥16 | ≥10 | ≥12 |

| Exfoliation | corrosion | - | ≦PB | |

| Intergranular corrosion | Mg/cm2 | - | ≦15 | |

| Certification | DNV, GL, ABS, CCS, BV, LR | |||

Applications of 5083 Marine Aluminum Plates

1. Decks

5083 aluminum plates are commonly used for the deck structures of vessels due to their high strength and corrosion resistance. The deck is one of the most important components of a vessel, needing to withstand multiple pressures from weather, seawater, and daily use. The characteristics of 5083 aluminum plates allow them to maintain good stability and safety in harsh marine environments. Especially during navigation, decks face high-intensity impacts and wear; the toughness and fatigue resistance of 5083 aluminum plates effectively prevent structural damage, ensuring the safety of crew and cargo.

2. Engine Mounts

The lightweight characteristics of 5083 aluminum plates make them an ideal material for engine mounts. In vessel design, reducing overall weight is one of the important factors to enhance performance. Lightweight not only improves vessel speed and fuel efficiency but also lowers the center of gravity, increasing stability. The combination of high strength and low density of 5083 aluminum plates provides significant advantages for applications in engine compartments, reducing the additional burden on the vessel's structure.

3. Hull and Bottom Outer Plates

The hull and bottom outer plates of vessels must withstand the impact of seawater and the pressure of waves, which imposes high demands on material strength and corrosion resistance. The excellent performance of 5083 aluminum alloy effectively resists the erosion from water flow and mechanical damage, ensuring the safety and integrity of the hull. Additionally, due to its good weldability, 5083 aluminum plates can be efficiently combined with other materials or components, ensuring the overall integrity and stability of the hull structure.

4. Other Components

The application range of 5083 aluminum plates also includes various other components of vessels, such as:

- Anti-Wave Boards: Used to prevent wave attacks, protecting the hull and deck.

- Cabin Structures: Its high strength and corrosion resistance ensure the durability and safety of vessel cabins.

- Cargo Holds: The lightweight and high-strength design of 5083 aluminum plates makes them very suitable for cargo hold structures, improving the loading capacity and stability of the holds.

5053 Marine Grade Aluminum Plate Sheet Stock List

| Product Description | Thickness | Type |

| 5083 H116 Marine Grade Aluminum Sheet | 0.125" | Sheet |

| 0.125" 5083 H321 Marine Grade Aluminum Sheet | 0.125" | Sheet |

| 4mm/0.160" 5083 H116 Marine Grade Aluminum Sheet | 4mm/0.160" | Sheet |

| 0.19" 5083 H116 Marine Grade Aluminum Sheet | 0.19" | Sheet |

| 5mm/0.197" 5083 H116 Marine Grade Aluminum Sheet | 5mm/0.197" | Sheet |

| 6mm/0.236" 5083 H116 Marine Grade Aluminum Plate | 6mm/0.236" | Plate |

| 0.25" 5083 H116 Marine Grade Aluminum Plate | 0.25" | Plate |

| 0.313" 5083 H116 Marine Grade Aluminum Plate | 0.313" | Plate |

| 0.375" 5083 H116 Marine Grade Aluminum Plate | 0.375" | Plate |

| 0.375" 5083 H32 Marine Grade Aluminum Plate | 0.375" | Plate |

| 0.375" 5083 H321 Marine Grade Aluminum Plate | 0.375" | Plate |

| 10 mm/0.394" 5083 H116 Marine Grade Aluminum Plate | 10 mm/0.394" | Plate |

| 12 mm/0.472" 5083 H116 Marine Grade Aluminum Plate | 12 mm/0.472" | Plate |

| 0.5" 5083 H116 Marine Grade Aluminum Plate | 0.5" | Plate |

| 0.5" 5083 H32 Marine Grade Aluminum Plate | 0.5" | Plate |

| 0.5" 5083 H321 Marine Grade Aluminum Plate | 0.5" | Plate |

| 0.625" 5083 H116 Marine Grade Aluminum Plate | 0.625" | Plate |

| 0.625" 5083 H32 Marine Grade Aluminum Plate | 0.625" | Plate |

| 0.75" 5083 H116 Marine Grade Aluminum Plate | 0.75" | Plate |

| 0.75" 5083 H32 Marine Grade Aluminum Plate | 0.75" | Plate |

| 0.75" 5083 H321 Marine Grade Aluminum Plate | 0.75" | Plate |

| 1" 5083 H116 Marine Grade Aluminum Plate | 1" | Plate |

| 1" 5083 H321 Marine Grade Aluminum Plate | 1" | Plate |

| 1.25" 5083 H32 Marine Grade Aluminum Plate | 1.25" | Plate |

| 1.25" 5083 H321 Marine Grade Aluminum Plate | 1.25" | Plate |

| 1.375" 5083 H116 Marine Grade Aluminum Plate | 1.375" | Plate |

| 1.5" 5083 H321 Marine Grade Aluminum Plate | 1.5" | Plate |

| 2" 5083 H321 Marine Grade Aluminum Plate | 2" | Plate |

| 2.25" 5083 H321 Marine Grade Aluminum Plate | 2.25" | Plate |

| 2.5" 5083 H321 Marine Grade Aluminum Plate | 2.5" | Plate |

| 3" 5083 H321 Marine Grade Aluminum Plate | 3" | Plate |

| 3.25" 5083 H321 Marine Grade Aluminum Plate | 3.25" | Plate |

| 3.5" 5083 H321 Marine Grade Aluminum Plate | 3.5" | Plate |

| 4.25" 5083 H321 Marine Grade Aluminum Plate | 4.25" | Plate |

| 6.000" 5083 H321 Marine Grade Aluminum Plate | 6.000" | Plate |

Marine aluminum products you may be interested in

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

5059 Marine Grade Aluminum Plate Sheet

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5383 Marine Grade Aluminum Plate Sheet

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.