5086 Aluminum Flat Bar

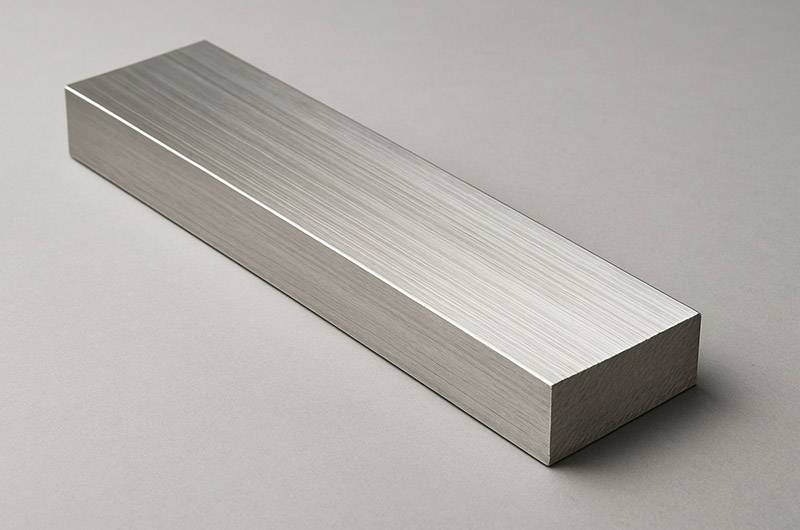

5086 aluminum flat bar is an aluminum profile processed based on 5086 aluminum alloy, primarily used in industrial manufacturing.

5086 aluminum flat bar is a high-strength, corrosion-resistant component, mainly used in shipbuilding, military, and industrial applications. These aluminum bars are made from aluminum-magnesium alloy and perform excellently in harsh environments.

With its comprehensive performance, 5086 aluminum flat bar occupies an important position in shipbuilding, marine engineering, and supporting equipment. Its application not only enhances the durability and safety of marine equipment but also reduces energy consumption through lightweight design, making it an indispensable and efficient material in the marine industry.

Haomei Aluminum specializes in the production of 5086 aluminum flat bars, using high-quality aluminum-magnesium alloy material. It features high strength, excellent seawater corrosion resistance, and superior weldability, making it suitable for shipbuilding, automotive structures, chemical equipment, and other fields. Complete product specifications (thickness 5-50mm, width 20-200mm) are available, custom orders supported, OEM service provided. Direct sale from the manufacturer, favorable prices, strict quality control to ensure compliance with ASTM, EN, and other international standards. Bulk orders are welcome, sample delivery available.

5086 Aluminum Flat Bar Features

- Alloy Composition: Magnesium content approximately 3.5-4.5%, with small amounts of manganese, chromium, and other elements.

- Strength: Non-heat treatable; strength is achieved through strain hardening. In H116 temper, its yield strength is 30 ksi, and ultimate tensile strength is 42 ksi.

- Corrosion Resistance: Excellent seawater corrosion resistance makes it an ideal choice for marine environments.

- Weldability: Good weldability, with weld strength remaining strong after welding. Common welding methods include MIG, TIG, and friction stir welding.

- Formability: Easily shaped into various shapes and sizes, suitable for customized applications.

5086 Aluminum Flat Bar Chemical Composition

5086 aluminum alloy is a magnesium-based alloy in the 5xxx series, known for its excellent corrosion resistance. The typical composition includes:

- Aluminum (Al): ~93.5–96.3%

- Magnesium (Mg): 3.5–4.5% (main alloying element)

- Manganese (Mn): 0.2–0.7%

- Chromium (Cr): 0.05–0.25%

- Iron (Fe), Silicon (Si), Copper (Cu), Zinc (Zn): trace elements (total content <0.5%).

5086 Aluminum Flat Bar Mechanical and Physical Properties

Non-heat treatable: Strengthened through strain hardening (e.g., H32, H116 temper).

Mechanical Properties (H116 temper):

- Tensile Strength: ~290 MPa

- Yield Strength: ~215 MPa

- Elongation: ~12%

Physical Properties:

- Density: 2.7 g/cm³

- Melting Range: 570–640°C

- Thermal Conductivity: 125 W/m·K

- Electrical Conductivity: ~29% IACS

5086 Aluminum Flat Bar Applications

5086 Aluminum Flat Bar in the Marine Industry

Core Structural Components in Shipbuilding

- Hull and Deck: 5086 aluminum flat bar is commonly used in hull outer plates, decks, sides, and bottom structures of ships. Its excellent seawater corrosion resistance effectively handles long-term immersion in marine environments, reducing maintenance costs, while its moderate strength ensures the stability of the hull structure.

- Engine Mounts and Welded Components: Its good weldability makes it suitable for welded structural components such as engine mounts and bulkhead connectors, ensuring structural integrity and airtightness.

Marine Engineering Equipment and Storage & Transport Equipment

- LNG Tanks and Cryogenic Containers: 5086 aluminum alloy maintains excellent mechanical properties in low-temperature environments, making it suitable for manufacturing liquefied natural gas (LNG) tanks, refrigerated containers, and cryogenic liquid transport tanks, meeting strict explosion-proof and low-temperature requirements.

- Offshore Platforms and Drilling Equipment: 5086 aluminum flat bar is used in offshore oil and gas platforms, drilling equipment to support structures and protective housings, with its salt spray corrosion resistance extending the equipment's service life.

Ship Protection and Special Purposes

- Armor Plates and Bulletproof Structures: 5086’s high strength and impact resistance make it ideal for armor protection plates on naval vessels, especially in military ships that require both lightweight and corrosion resistance.

- Anti-slip Decks and Fittings: By surface treatment (e.g., patterned rolling), 5086 aluminum flat bar can be made into anti-slip decks, widely used in yachts, ferries, and other ships to enhance safety.

Supporting Equipment and Auxiliary Systems

- Pipelines and Pressure Vessels: Used in ship fuel pipelines, seawater cooling systems, and non-combustible pressure vessels, its corrosion resistance reduces the risk of leaks due to media erosion.

- Electrical Equipment Housings: In ship distribution cabinets, high-voltage switchgear housings, etc., 5086’s corrosion resistance protects internal components from the impact of the marine humid environment.

Here’s the technical advantage and application scenario for 5086 aluminum flat bars in a table format:

| Technical Advantage | Details |

| Corrosion Resistance | 5086 Aluminum contains 3.5%-4.5% Magnesium, along with trace amounts of Manganese and Chromium, forming a dense oxide layer. This significantly enhances its resistance to seawater and salt spray corrosion, especially in long-term immersion environments. |

| Welding and Machining Performance | Excellent cold working performance, can be formed at room temperature without preheating. High welding compatibility (e.g., gas welding, arc welding), and welds have high strength, making it suitable for complex hull structure manufacturing. |

| Lightweight and Strength Balance | Low density (about 2.7 g/cm³), with a tensile strength of over 240 MPa. This allows it to reduce the weight of the hull while maintaining structural strength, in line with the trend toward lightweight shipbuilding. |

| Certifications and Standardization | Certified by classification societies (e.g., CCS, DNV), and compliant with international standards like ASTM and EN, ensuring material reliability in marine environments. |

What Other Fields is 5086 Aluminum Flat Bar Used In?

- Military: Vehicle armor.

- Industrial: Pressure vessels, cryogenic equipment, oil and gas pipelines, and structural supports.

- Transportation: Rail vehicle components, truck bodies.

Available Sizes of 5086 Aluminum Flat Bar

| Specification | Details |

| Thickness | 0.25 inches to 6 inches (6.35 mm to 152.4 mm) |

| Width | Up to 48 inches (1219 mm) |

| Length | Standard: 12 feet to 20 feet (3.6 m to 6.1 m); Custom lengths available (12 inches, 24 inches, 36 inches standard) |

| Surface Treatment | Standard: Mill Finish; Optional: Anodized/Brushed finish for aesthetics or corrosion resistance |

| Standards | ASTM B209 (Sheet/Plate), AMS 4346 |

| Common Tempers | H32 (Work-Hardened + Stabilized), H116 (Optimized for Marine Corrosion Resistance) |

Corrosion Resistance of 5086 Aluminum Flat Bar

- Performs excellently in marine and industrial environments.

- Resistant to stress corrosion cracking (SCC) and saltwater pitting.

- Due to its inherent durability, it is often used without painting.

Advantages Compared to Alloys (e.g., 6061, 5083)

- Compared to 6061, it has superior corrosion resistance in marine environments.

- Compared to 5083 with higher magnesium content, it offers a more balanced strength and formability.

Compared to the commonly used 5083 aluminum alloy, 5086 has the following advantages:

- Mechanical properties: 5086 has higher tensile strength than 5083, making it suitable for higher load scenarios.

- Composition optimization: 5086 has slightly lower magnesium content but an appropriately higher zinc content, further optimizing its corrosion resistance and work hardening ability.

5086 Aluminum Flat Bar is ideal for demanding environments that require weldability, formability, and long service life. Its marine-grade durability and versatility make it the preferred choice for engineers and manufacturers in harsh conditions.

5086 Aluminum Flat Bar Processing and Manufacturing

5086 Aluminum Flat Bar Processing:

- Cutting: Cut to specified lengths using saws or shears.

- Forming: Excellent cold forming properties; for severe deformation, annealing is recommended. Can be bent and shaped to meet custom designs.

- Machining: Can be drilled, tapped, or milled for specific applications. Moderate machinability; lubrication may be needed to prevent sticking.

5086 Aluminum Flat Bar Welding:

Welding: Suitable for various welding processes, with strength maintained after welding. Compatible with MIG/TIG welding, using 5356 filler wire. Avoid overheating to preserve corrosion resistance.

Recommended for you

-

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

-

5086 aluminum alloy round bars achieve high strength through cold mechanical processing, offering excellent seawater corrosion resistance and weldability. They are specifically designed for shipbuilding, marine engineering, and transportation equipment.

-

As a professional aluminum alloy material manufacturer, we offer 5086 H111 aluminum alloy round bars, specially designed for harsh environments, suitable for shipbuilding, marine engineering, and industrial structural fields.

Other content readers are interested in

-

5086 marine grade aluminium checkered tread plate sheet

5086 marine grade aluminum checkered tread plate sheet has higher strength and corrosion resistance than 5052 and 5083 plates, making it ideal for many marine and marine applications.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

As a direct manufacturer of 5086 Aluminum Sheet, we offer marine-grade aluminum plates that meet ASTM B209/EN 485 standards, featuring excellent seawater corrosion resistance and weldability.

-

As a professional aluminum plate manufacturer, we offer high-performance 5086 H116 aluminum alloy plates in a variety of specifications to meet the lightweight and industrial requirements of hulls.

-

As a leading manufacturer of aluminum alloys, we specialize in supplying 5086 H32 aluminum plate, ideal for harsh marine, industrial, and structural applications.

-

Our company specializes in the production of 5086 H111 medium-thick aluminum plates, with a finely polished surface and strong resistance to seawater corrosion. We offer customized cutting and welding services, and provide international certifications such as BV/DNV/ABS, with quick response to custom needs.

-

As a professional manufacturer of 5086 aluminum tubes, we offer seamless cold drawn aluminum tubes that comply with ASTM B210/B221 standards, with material strengthened by magnesium alloys, combining high strength and excellent seawater corrosion resistance.

-

5086 Aluminum Round Tubes and Pipes

As a professional aluminum alloy tube manufacturer, we offer 5086 aluminum alloy seamless round tubes, produced using high-precision cold drawing processes, conforming to international standards such as ASTM B210.

-

As a professional aluminum material manufacturer, we offer high-quality 5086 aluminum alloy square tubes, specifically designed for ships, marine engineering, and high-corrosion environments.

-

5086 Aluminum Drawn Seamless Pipe

As a leading manufacturer of precision aluminum products, we specialize in producing 5086 Aluminum Drawn Seamless Pipes designed for harsh environments.

-

As a professional 5086 H32 pipe manufacturer, we provide high-performance, seawater corrosion-resistant customized pipe products, combining excellent strength and lightweight properties. Non-standard size processing is supported, and products are tested according to ISO certification and ASTM/EN standards.

-

As a leading supplier of 5086 aluminum alloy angles, we offer a full range of sizes in 5086-H111 structural angles, suitable for marine ladders, pressure vessels, and transportation equipment.

-

As a professional aluminum material manufacturer, we provide 5086 H111 aluminum alloy angles, combining high strength and excellent corrosion resistance, especially suitable for the marine, offshore engineering, and industrial structural fields.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5454 aluminum alloy not only possesses excellent corrosion resistance, but its unique high-temperature stress resistance makes it irreplaceable in welded structures for ship fuel tanks and high-temperature environments.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

More content of interest to readers

What is the difference between 5086 and 6061 aluminum? 5086 H32 vs H116 What is 5086 grade aluminum? 5086 Aluminum vs 5052 5086 Aluminum vs. 5456 Aluminum 5086 and 5083 Aluminum Materials in Shipbuilding

Tags: Marine Aluminum 5086