5086 Aluminum Sheet

5086 aluminum sheet is an aluminum-magnesium alloy material, belonging to the anti-rust aluminum series, known for its high corrosion resistance, good weldability, and medium strength.

5086 aluminum is part of the 5xxx series, renowned for its strength, weldability, and corrosion resistance. It cannot be heat treated but can achieve strength through cold working.

5086 is an aluminum-magnesium forging alloy, known for its marine-grade corrosion resistance and medium strength. Due to its seawater corrosion resistance, 5086 is widely used in shipbuilding and marine structures (such as hull plates, decks, superstructures). It is also found in transportation applications (fuel tanks, rail vehicles, truck bodies), pressure vessels/cryogenic storage tanks (pipes, storage), as well as military/armor applications (vehicle armor, patrol boat hulls). For example, due to its strength and toughness, 5086 is widely used in the U.S. Navy's vessels and armored vehicles.

Haomei Aluminum, as a direct manufacturer of 5086 Aluminum Sheet, provides marine-grade aluminum plates that meet ASTM B209/EN 485 standards, with excellent seawater corrosion resistance and weldability. Customization in H116/H321 tempers is supported, with thicknesses ranging from 0.5 to 150mm, suitable for shipbuilding, marine engineering, and pressure vessel fields. Direct sales from the manufacturer, quality certification, fast delivery, and support for global supply chain needs.

In marine and industrial applications, 5086’s outstanding corrosion resistance and weldability make it an ideal choice for hulls, offshore platforms, and similar structures. It is also used in automotive fuel tanks, heavy equipment, building structures, and chemical processing equipment.

5086 alloy exhibits excellent corrosion resistance in seawater and industrial environments, making it the first choice for marine applications. Its excellent weldability (via MIG, TIG, and friction stir welding) ensures that its strength remains close to the O condition after welding. Typical applications include ship and yacht hulls, ship deck structures, vehicle armor, and structural components in the transportation industry.

5086 Aluminum Sheet Chemical Composition

Major Alloying Elements

- Magnesium (Mg): 3.5–4.5 wt %

- Manganese (Mn): 0.2–0.7 wt %

- Chromium (Cr): 0.05–0.25 wt %

- Trace Elements and Limits

- Iron (Fe): ≤ 0.5 wt %

- Silicon (Si): ≤ 0.4 wt %

- Copper (Cu): ≤ 0.1 wt %

- Titanium (Ti): ≤ 0.15 wt %

- Zinc (Zn): ≤ 0.25 wt %

- Others (each): ≤ 0.05 wt %; Total of other elements: ≤ 0.15 wt %

- Remainder: Aluminum (Al)

5086 Aluminum Sheet Physical Properties

| Property | Value |

| Density | 2.66 g/cm³ |

| Melting Range | 585–640 °C |

| Electrical Conductivity | ~18 MS/m |

| Thermal Conductivity (25 °C) | ~126 W/m·K |

| Thermal Expansion (20–100 °C) | 23.8×10⁻⁶ /°C |

| Modulus of Elasticity | ~71 GPa |

Available Tempers for 5086 Aluminum Sheet

- H116: Optimized for corrosion resistance in marine applications.

- H32, H34: Strain-hardened to increase strength.

5086 Aluminum Sheet Standards and Certifications

5086 Aluminum Sheet Standards

5086 plates and sheets are produced according to international standards. The main standards include:

ASTM / ASME:

- ASTM B209 (Aluminum and Aluminum-Alloy Sheet and Plate) – Covers 5086 sheet/plate in H32/H116 tempers. Plate and sheet thicknesses can go up to several inches.

- ASTM B928 (Plate and Sheet for Shipbuilding) – Covers 5086 (and other 5xxx alloys) for shipbuilding applications (general specification for 5086 sheet).

- ASTM B221 – Applies to extruded shapes (such as 5086 extruded shapes, if used).

- ASTM B210/B241 – Applies to pipe and tube products (5086 is used for low-temperature/low-pressure piping).

- ASME SB-209/SB-928 – Corresponding ASME Boiler and Pressure Vessel Code names (e.g., SB-209 applies to thin sheet/plate).

Federal / Military:

- QQ-A-250/7 – An older federal specification for 5086 sheet/plate (commonly referenced with AMS 4150 for these types of alloys).

- MIL-S-24149/2 and MIL-C-26094 – Possible military specifications including 5086 (C-26094 applies to coatings, S-24149 applies to aluminum plates). Manufacturers often dual-certify to these specifications.

- AMS 4150/5086 – Aerospace material specification (AMS 4150 applies to 5086-H116 sheet), sometimes used for special applications.

ISO / EN:

- ISO 6361-2 – Mechanical properties requirements for forged aluminum plates/sheets (covers various tempers of 5086 aluminum sheet).

- EN AW-5086 (AlMg4) – European grade and composition (AlMg4 corresponds to 5086). Applicable EN standards include EN 485-2 (mechanical properties) and EN 573-3 (composition).

5086 Aluminum Sheet Certifications

Certifications: Sheets and plates are typically certified by classification societies and end-users. Marine-grade 5086 typically holds ABS, DNV, Lloyd's Register, or CCS shipbuilding certifications.

Available Thicknesses and Dimensions for 5086 Aluminum Sheet

| Parameter | Description |

| Thickness | Sheet: Typically starts at 0.2 mm (about 0.008 inches) |

| Plate: Up to 75 mm (3 inches) or thicker | |

| Custom thick plates: Up to 300 mm (in thick plate mills) | |

| Width | Standard width range: 500-2500 mm (20-100 inches) |

| Length | Standard length: Up to 10-12 meters (40 feet) |

| Medium-thick plates typically shorter in length: 3-6 meters | |

| Custom lengths can be cut as required | |

| Flatness and Tolerances | Sheet thickness tolerance: ±0.005 inches (±0.13 mm) |

| Thicker plate tolerance: ±0.01-0.02 inches | |

| Width tolerance: ±0.062 inches (±1.6 mm) | |

| Length tolerance: ±1/16 inches (±1.6 mm) | |

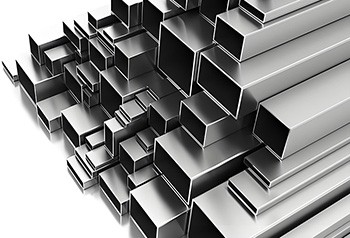

| Shape | In addition to flat sheets and plates, tread plate, coils, extruded shapes, and tubes are also available |

| Pre-coated forms (PVC, anodized, painted) and tread plate forms are available |

5086 Aluminum Sheet Surface Treatment and Dimensions

- Surface treatment: Smoothness, anodizing, painting, or coating.

- Thickness range: Typically from 0.5 mm to 150 mm, depending on the supplier.

5086 Aluminum Sheet Advantages and Limitations

- Advantages: Strong corrosion resistance, good weldability, excellent low-temperature properties.

- Limitations: Lower strength compared to other 5xxx alloys (such as 5083); not heat treatable.

5086 aluminum sheet is well-suited for applications requiring a balance of strength, formability, and durability in corrosive environments. Its versatility makes it a top choice in the marine and transportation industries.

5086 Aluminum Sheet Mechanical Properties for Different Tempers

| Mechanical Properties | H116 Temper | H32 Temper | O Temper |

| Yield Strength | 200-210 MPa (29-31 ksi) | 195 MPa (approx.) | Approx. 150 MPa |

| Tensile Strength | 290-300 MPa (42-44 ksi) | Up to 325 MPa (47 ksi) | Approx. 290 MPa (International Alloy Data) |

| Elongation | 10-12% (thick plate, strain-hardened temper) | 10-12% | Over 16% |

| Hardness | Brinell Hardness 78-81 HB | Brinell Hardness approx. 70 | Low hardness |

| Modulus of Elasticity | 68-71 GPa (≈10×10^6 psi) | 68-71 GPa | 68-71 GPa |

| Fatigue Strength | Approx. 150 MPa (22 ksi), 10^7 cycles | Approx. 150 MPa (22 ksi) | Approx. 150 MPa |

| Shear Strength | Approx. 175 MPa | Approx. 175 MPa | Approx. 175 MPa |

Notes:

- Yield Strength: The yield strength in H116 temper is higher, while it is lower in H32 and O temper.

- Tensile Strength: The tensile strength in H32 temper is the highest, up to 325 MPa (47 ksi).

- Elongation: The elongation in H116 temper is lower, while the O temper elongation exceeds 16%, offering better ductility.

- Hardness: The hardness in H116 temper is the highest, while it is lower in H32 and the lowest in O temper.

- Fatigue Strength: The fatigue strength is similar across H116, H32, and O tempers, around 150 MPa.

- Shear Strength: The shear strength of 5086 aluminum alloy is approximately 175 MPa across all tempers.

Overall, 5086 aluminum alloy has medium to high strength in cold-worked conditions, with good ductility, especially in the O temper.

Note: Other tempers include H34, H112, H321, etc. Each temper balances strength, ductility, and stress-relieving performance to meet specific manufacturing needs.

5086 Aluminum Sheet Corrosion Resistance

- Excellent resistance to marine and industrial environment corrosion.

- Resistant to stress corrosion cracking (SCC), performing well in chloride-rich environments.

5086 is highly regarded for its exceptional corrosion resistance, especially in marine and atmospheric environments. It "forms a protective oxide and has a strong inherent resistance to seawater stress corrosion cracking." In practice, 5086 sheet material shows virtually no loss of strength or deep pitting even after years of immersion in seawater. It is often referred to as "rustproof" aluminum.

| Environment | Corrosion Resistance | Notes |

| Seawater | Excellent | Excellent resistance to general corrosion, pitting, and crevice corrosion in saltwater, far superior to 3000/6000 series alloys. |

| After being fully submerged in seawater for 5 years, there is almost no pitting. | ||

| Suitable for hulls, floating docks, and offshore structures. | ||

| Atmospheric | Very Good | Forms a stable Al₂O₃ film in air, providing self-protection. |

| Good weather resistance in urban, industrial, and marine environments. | ||

| May require anodizing or painting protection in severely polluted or salt-spray environments. | ||

| Industrial/Chemical | Suitable | Suitable for a variety of environments, such as weak acids and weak alkalis. |

| Commonly used in chemical tanks and cryogenic vessels. | ||

| Should not be used in strong alkaline solutions (pH > 9.5) or low-oxygen acids. | ||

| Stress Corrosion | Possible | The 5086 alloy may experience stress corrosion cracking (SCC) under continuous tensile stress and corrosive conditions, especially in high-strength tempered alloys. |

| Using H116 alloy can reduce the risk of stress corrosion, but sharp notches and excessive pre-stress should be avoided. |

Notes:

- Seawater Corrosion: 5086 aluminum alloy exhibits excellent corrosion resistance in seawater, making it an ideal choice for marine applications.

- Atmospheric Corrosion: In atmospheric environments, 5086 aluminum alloy shows good corrosion resistance and can withstand urban, industrial, and marine conditions.

- Industrial/Chemical Environments: Suitable for most weak acid and weak alkali environments, but not suitable for strong alkaline or low-oxygen acid conditions.

- Stress Corrosion: Although 5086 has good overall corrosion resistance, stress corrosion cracking (SCC) may occur when subjected to sustained tensile stress and corrosive conditions, especially in high-strength tempered alloys. Therefore, sharp notches and high pre-stress should be avoided in design.

The 5086 alloy combines corrosion resistance and strength, making it a marine-grade alloy. Due to its exceptional seawater performance, it is often chosen as the material for submerged hulls and seawater equipment, rather than 5052 or 6061.

- Seawater and Marine Atmosphere: 5086 alloy exhibits excellent pitting and general corrosion resistance in seawater, outperforming many 5xxx series alloys.

- Industrial Chemicals: Maintains excellent integrity when exposed to industrial chemicals, oils, and cleaners.

- Stress Corrosion Cracking (SCC): While generally corrosion-resistant, prolonged exposure to tensile stress in corrosive environments may induce SCC; selecting an appropriate temper (such as H116) can reduce the risk.

5086 Aluminum Sheet Processing Characteristics

- Weldability: Excellent; suitable for TIG, MIG, and resistance welding, with minimal strength loss.

- Formability: Good formability in the annealed condition; higher hardness steels may require annealing to form complex shapes.

- Machinability: Moderate; it is recommended to use sharp tools and lubrication.

5086 Aluminum Sheet Weldability and Fabrication

5086 has excellent weldability. As a non-heat treatable alloy, welding does not result in severe heat treatment effects. Typical welding considerations:

| Properties | Description |

| Weldability | Excellent |

| Arc Welding (MIG/TIG) | 5086 can be easily welded using Gas Metal Arc Welding (GMAW) (MIG) or Gas Tungsten Arc Welding (GTAW) (TIG). The welds retain most of the base metal strength. |

| Studies show that the strength of H116 welds only decreases to a level similar to the annealed (O temper) state, with less strength loss compared to many 6xxx alloys. | |

| 5356 or 5183 (aluminum-magnesium alloys) are commonly used as filler materials. | |

| Friction Stir Welding (FSW) | FSW works well with 5086, producing fine-grain, high-strength joints, widely used in large panels and shipbuilding. |

| Formability | In annealed or low-hardened conditions, it has good cold formability (rolling, bending, stretching). It can be rolled into sheets or bent into various shapes (within strain limits). |

| In the O state, it has excellent cold-working properties, while in H38/H36 states, formability is slightly worse. High-strength cold working (H32/H34) increases hardness but still allows forming. | |

| Machinability | Relatively poor. |

| Like other 5xxx alloys, 5086 is tougher on tools than 6xxx alloys. | |

| Requires lower cutting speeds, careful setup, and sharp tools. Its high work hardening requires careful handling of scrap material. |

Notes:

- Arc Welding (MIG/TIG): 5086 has excellent arc welding properties, with good strength retention after welding, making it particularly suitable for welding aluminum-magnesium alloys.

- Friction Stir Welding (FSW): 5086 alloy works well with friction stir welding, especially for large panels and shipbuilding.

- Formability: 5086 has excellent cold formability in the softer annealed state (O state), but its formability is slightly worse in harder states (such as H38/H36).

- Machinability: 5086 has relatively poor machinability, requiring tougher tools and lower cutting speeds, and special care in handling scrap material during machining.

Post-Weld Performance: As mentioned above, the weld area and heat-affected zone typically end up in the annealed state. This means the joint strength is comparable to that of O-temper material, which may be about 50-60% of the original strain-hardened strength. Therefore, weld design must account for the softened zone, but in practice, this characteristic of 5086 alloy is well understood. No special post-weld heat treatment is required (as it cannot be strengthened through heat treatment).

5086 alloy is easy to weld and fabricate. It rarely presents issues. In its softer temper state, it has good formability, and although its machinability is limited, it can be cut and drilled using conventional methods (using carbide tools and cutting fluids).

5086 Aluminum Sheet Applications

- Shipbuilding and Offshore Engineering: Hulls, decks, bulkheads, and superstructures (especially below the waterline coatings). Its high magnesium content makes it one of the most corrosion-resistant alloys to seawater, commonly referred to as "rustproof alloy."

- Transportation: Fuel and oil tankers, truck/trailer bodies, rail vehicle panels, and structural components for buses and heavy vehicles. Its light weight and high strength improve efficiency and payload capacity.

- Cryogenic and Pressure Vessels: Used for liquefied natural gas, liquefied petroleum gas, and chemical processing storage/transport tanks. It maintains toughness at low temperatures and provides good formability for tank manufacturing.

- Structural and Architectural: Building frames, bridges, transmission towers, and riveted/assembled structures (in the U.S., aluminum is commonly used to reduce weight).

- Defense: Armor plates and military vehicle components (e.g., M113 armored personnel carriers, M2 Bradley infantry fighting vehicles). Its combination of welding strength and toughness is crucial for military vehicle hulls and armor.

5086 Aluminum Sheet vs. Similar Alloys

- 5083: Higher magnesium content (4.0-4.9%), higher strength but poorer formability.

- 5052: Lower magnesium content (2.2-2.8%), better formability and corrosion resistance, but lower strength.

Recommended for you

-

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

As a professional aluminum plate manufacturer, we offer high-performance 5086 H116 aluminum alloy plates in a variety of specifications to meet the lightweight and industrial requirements of hulls.

-

As a leading manufacturer of aluminum alloys, we specialize in supplying 5086 H32 aluminum plate, ideal for harsh marine, industrial, and structural applications.

-

Our company specializes in the production of 5086 H111 medium-thick aluminum plates, with a finely polished surface and strong resistance to seawater corrosion. We offer customized cutting and welding services, and provide international certifications such as BV/DNV/ABS, with quick response to custom needs.

Other content readers are interested in

-

5086 marine grade aluminium checkered tread plate sheet

5086 marine grade aluminum checkered tread plate sheet has higher strength and corrosion resistance than 5052 and 5083 plates, making it ideal for many marine and marine applications.

-

5059 5086 Marine Grade Aluminum Bars

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

-

As a professional manufacturer of 5086 aluminum tubes, we offer seamless cold drawn aluminum tubes that comply with ASTM B210/B221 standards, with material strengthened by magnesium alloys, combining high strength and excellent seawater corrosion resistance.

-

5086 Aluminum Round Tubes and Pipes

As a professional aluminum alloy tube manufacturer, we offer 5086 aluminum alloy seamless round tubes, produced using high-precision cold drawing processes, conforming to international standards such as ASTM B210.

-

As a professional aluminum material manufacturer, we offer high-quality 5086 aluminum alloy square tubes, specifically designed for ships, marine engineering, and high-corrosion environments.

-

5086 Aluminum Drawn Seamless Pipe

As a leading manufacturer of precision aluminum products, we specialize in producing 5086 Aluminum Drawn Seamless Pipes designed for harsh environments.

-

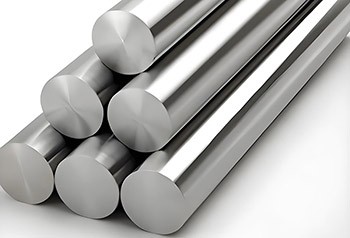

5086 aluminum alloy round bars achieve high strength through cold mechanical processing, offering excellent seawater corrosion resistance and weldability. They are specifically designed for shipbuilding, marine engineering, and transportation equipment.

-

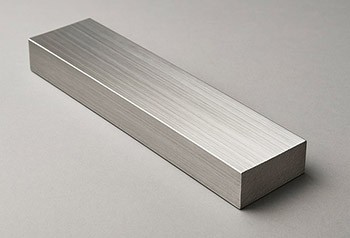

Professional production of 5086 aluminum flat bars, complete product specifications, direct sale from the manufacturer, favorable prices, strict quality control to ensure compliance with ASTM, EN, and other international standards.

-

As a professional aluminum alloy material manufacturer, we offer 5086 H111 aluminum alloy round bars, specially designed for harsh environments, suitable for shipbuilding, marine engineering, and industrial structural fields.

-

As a professional 5086 H32 pipe manufacturer, we provide high-performance, seawater corrosion-resistant customized pipe products, combining excellent strength and lightweight properties. Non-standard size processing is supported, and products are tested according to ISO certification and ASTM/EN standards.

-

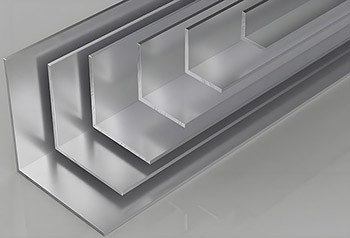

As a leading supplier of 5086 aluminum alloy angles, we offer a full range of sizes in 5086-H111 structural angles, suitable for marine ladders, pressure vessels, and transportation equipment.

-

As a professional aluminum material manufacturer, we provide 5086 H111 aluminum alloy angles, combining high strength and excellent corrosion resistance, especially suitable for the marine, offshore engineering, and industrial structural fields.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

More content of interest to readers

What is the difference between 5086 and 6061 aluminum? 5086 H32 vs H116 What is 5086 grade aluminum? 5086 Aluminum vs 5052 5086 Aluminum vs. 5456 Aluminum 5086 and 5083 Aluminum Materials in Shipbuilding

Tags: Marine Aluminum 5086