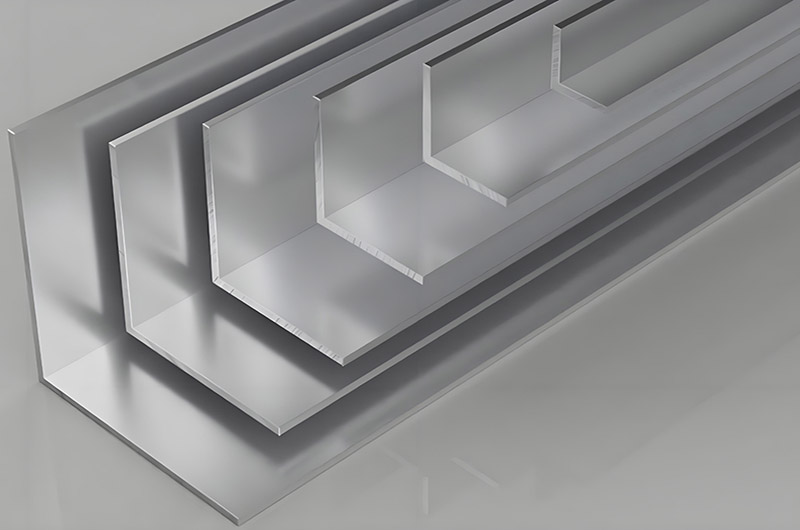

5086 H111 Aluminum Angle

The 5086 H111 aluminum angle is made from 5086 aluminum alloy, processed in the H111 temper.

5086-H111 aluminum angle is a high-strength marine-grade alloy, primarily composed of aluminum and magnesium. The H111 temper indicates that the material has undergone strain hardening, with strength lower than the H11 temper, achieving a balance between strength and ductility.

Haomei Aluminum, as a professional aluminum material manufacturer, provides 5086 H111 aluminum alloy angles, using high-quality aluminum-magnesium alloys, combining high strength and excellent corrosion resistance, particularly suitable for the marine, offshore engineering, and industrial structural fields.

5086 H111 Aluminum Angle Properties

- Composition: Mainly composed of aluminum, with magnesium as the primary alloying element.

- Strength: Medium to high strength, suitable for structural applications.

- Corrosion Resistance: Excellent, especially suitable for marine environments, particularly for saltwater environments.

- Weldability: Good, easy to fabricate.

- Ductility: High, easy to bend and form.

- High strength-to-weight ratio.

5086 H111 Aluminum Angle Sizes

| Specifications | Details |

| Leg Length | Ranges from 1 inch to 2.5 inches |

| Thickness | Typically between 0.125 inches to 0.25 inches |

| Length | Standard stock length is 25 feet |

| Shape | L-shaped cross-section, equal or unequal legs |

| Manufacturing Method | Produced by extrusion or rolling |

| Standard Sizes | Various leg lengths (e.g., 1 inch x 1 inch to 6 inches x 6 inches) |

| Thickness Options | From 1/8 inch to over 1/2 inch, custom sizes available |

| Standards & Certifications | ASTM B221: Standard specification for extruded bars, rods, and profiles |

| EN 573-3: European standard for aluminum alloy grades | |

| AMS 4027: Aerospace material specification (for specific applications) |

5086 H111 Aluminum Angle Applications

5086 H111 Aluminum Angle in Marine Applications

- Marine Industry: Due to its excellent saltwater resistance, it is used in the construction of ships, ladders, and hulls.

- Shipbuilding: Used in hull frames, deck supports, etc., relying on its resistance to seawater corrosion.

- Ship: Used in hulls, ladders, and dock structures.

5086 H111 Aluminum Angle Also Used in Other Fields

- Construction: Structural components in buildings and infrastructure, curtain wall ribs, outdoor decorative corners, balancing strength and aesthetic needs.

- Transportation: Automotive body reinforcements, internal structures for rail vehicles, components for vehicles and cryogenic equipment.

- Industrial Equipment: Pressure vessel supports, refrigeration equipment frames, and other corrosion-resistant load-bearing components.

5086 H111 Aluminum Angle Alloy Composition

- Magnesium (Mg): 3.5%-4.5%, primarily enhancing corrosion resistance, especially suitable for marine environments.

- Manganese (Mn): 0.2%-0.7%, helps to strengthen the alloy and improve processing properties.

- Other elements (such as Si, Cu, Fe, etc.) are kept at low levels to ensure corrosion resistance and weldability.

5086 H111 Aluminum Angle Mechanical Properties

- Tensile Strength: ≥240 MPa, Yield Strength: ≥95 MPa.

- Elongation: δ10≥10%, δ5≥12%, indicating good ductility under stress.

- Hardness and Stability: The H111 treatment balances strength and deformation capability, making it suitable for dynamic load scenarios.

5086 H111 Aluminum Angle Temper

- Indicates the material has undergone slight cold working and partial annealing, retaining some work-hardened effect while also maintaining good formability.

- Compared to the H32 temper, H111 has slightly lower strength but higher plasticity, making it suitable for bending or stamping of angle profiles.

Processing Method: Strain hardening (rolling/extrusion), followed by partial annealing to achieve a stable condition.

5086 H111 Aluminum Angle Processing Characteristics:

- Compared to higher H tempers (e.g., H32, H34), the strength is moderate.

- Higher formability and ductility make it suitable for light forming after manufacturing.

- Balances machinability and strength retention.

5086 H111 Aluminum Angle Advantages

- Corrosion Resistance: Excellent performance in humid/chloride environments.

- Weldability: Maintains integrity after welding, with minimal strength loss.

- Formability: Easier to bend or form compared to fully strain-hardened tempered steel.

- Sustainability: Fully recyclable, with minimal environmental impact.

5086 H111 Aluminum Angle Processing and Manufacturing Tips

- Use sharp tools to prevent adhesion.

- Lubricate during drilling/cutting for better performance.

- Avoid excessive heating during processing to maintain tempering properties.

5086-H111 aluminum angle is an ideal choice for applications requiring corrosion resistance, moderate strength, and formability. Its versatility makes it the preferred choice in the marine, transportation, and industrial fields.

5086 H111 Aluminum Angle Manufacturing Considerations

- Processing: Can be easily cut, drilled, and machined using standard tools.

- Bending: Due to its high ductility, it can be bent to the desired angle without cracking.

- Surface Treatment: May require anodizing or painting to enhance corrosion resistance and aesthetic appearance.

Recommended for you

-

As a leading supplier of 5086 aluminum alloy angles, we offer a full range of sizes in 5086-H111 structural angles, suitable for marine ladders, pressure vessels, and transportation equipment.

Other content readers are interested in

-

5086 marine grade aluminium checkered tread plate sheet

5086 marine grade aluminum checkered tread plate sheet has higher strength and corrosion resistance than 5052 and 5083 plates, making it ideal for many marine and marine applications.

-

5059 5086 Marine Grade Aluminum Bars

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

As a direct manufacturer of 5086 Aluminum Sheet, we offer marine-grade aluminum plates that meet ASTM B209/EN 485 standards, featuring excellent seawater corrosion resistance and weldability.

-

As a professional aluminum plate manufacturer, we offer high-performance 5086 H116 aluminum alloy plates in a variety of specifications to meet the lightweight and industrial requirements of hulls.

-

As a leading manufacturer of aluminum alloys, we specialize in supplying 5086 H32 aluminum plate, ideal for harsh marine, industrial, and structural applications.

-

Our company specializes in the production of 5086 H111 medium-thick aluminum plates, with a finely polished surface and strong resistance to seawater corrosion. We offer customized cutting and welding services, and provide international certifications such as BV/DNV/ABS, with quick response to custom needs.

-

As a professional manufacturer of 5086 aluminum tubes, we offer seamless cold drawn aluminum tubes that comply with ASTM B210/B221 standards, with material strengthened by magnesium alloys, combining high strength and excellent seawater corrosion resistance.

-

5086 Aluminum Round Tubes and Pipes

As a professional aluminum alloy tube manufacturer, we offer 5086 aluminum alloy seamless round tubes, produced using high-precision cold drawing processes, conforming to international standards such as ASTM B210.

-

As a professional aluminum material manufacturer, we offer high-quality 5086 aluminum alloy square tubes, specifically designed for ships, marine engineering, and high-corrosion environments.

-

5086 Aluminum Drawn Seamless Pipe

As a leading manufacturer of precision aluminum products, we specialize in producing 5086 Aluminum Drawn Seamless Pipes designed for harsh environments.

-

5086 aluminum alloy round bars achieve high strength through cold mechanical processing, offering excellent seawater corrosion resistance and weldability. They are specifically designed for shipbuilding, marine engineering, and transportation equipment.

-

Professional production of 5086 aluminum flat bars, complete product specifications, direct sale from the manufacturer, favorable prices, strict quality control to ensure compliance with ASTM, EN, and other international standards.

-

As a professional aluminum alloy material manufacturer, we offer 5086 H111 aluminum alloy round bars, specially designed for harsh environments, suitable for shipbuilding, marine engineering, and industrial structural fields.

-

As a professional 5086 H32 pipe manufacturer, we provide high-performance, seawater corrosion-resistant customized pipe products, combining excellent strength and lightweight properties. Non-standard size processing is supported, and products are tested according to ISO certification and ASTM/EN standards.

Recommended for you

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

Marine Grade Flat Aluminum refers to flat, rectangular marine aluminum sheets or strips used in structural components, decks, and other flat surfaces on vessels.

-

Marine-grade angular aluminum is used for reinforcing edges, frames, and supports in marine structures with L-shaped or angled aluminum profiles. It is valued for its structural support and corrosion-resistant properties.

-

Marine Grade T-Type Aluminum Profiles

Marine T aluminum is a type of aluminum profile specifically designed for shipbuilding, primarily used for connecting or reinforcing hull parts at a vertical angle.

-

Marine Grade I-Type Aluminum Profiles

Marine-grade I-beam aluminum: An I-beam or H-beam aluminum profile used in marine applications requiring high strength, typically used in the construction of beams, joists, and structural supports.

-

Marine Grade Aluminum Square Tube

Marine Grade Square Tube: A type of hollow square aluminum profile used in frameworks, railings, and other structural applications where both strength and corrosion resistance are critical.

-

Marine-grade aluminum troughs: A U-shaped or channel profile used in drainage systems, cable management, and structural components in marine environments. They help guide or support materials while resisting corrosion.

-

Marine Grade Aluminum Bulb Flat extrusions

The advantages of Aluminum Bulb Flat Extrusions over other types of extrusions are significant. Compared to traditional extrusions such as angles or flats, bulb flats offer better performance in load distribution and structural reinforcement.

More content of interest to readers

What is the difference between 5086 and 6061 aluminum? 5086 H32 vs H116 What is 5086 grade aluminum? 5086 Aluminum vs 5052 5086 Aluminum vs. 5456 Aluminum 5086 and 5083 Aluminum Materials in Shipbuilding

Tags: Marine Aluminum 5086