5086 H111 Plate

5086-H111 Aluminum Plate is a marine-grade aluminum-magnesium alloy known for its outstanding corrosion resistance, moderate strength, and excellent weldability. It is widely used in maritime, transportation, and structural applications where durability in harsh environments is critical.

5086 is a non-heat-treatable aluminum-magnesium alloy from the 5xxx series, known for its excellent corrosion resistance, medium strength, and weldability. The H111 temper indicates that the alloy has undergone light strain hardening (rolling or cold working) followed by partial annealing to stabilize its properties, thus balancing formability and mechanical strength.

Haomei Aluminum specializes in the production of 5086 H111 medium-thick aluminum plates, with thickness ranging from 0.15-600mm to meet the demanding requirements of ships, automobiles, pressure vessels, and other harsh environments. We use advanced hot-rolling production lines, ensuring high precision (tolerance ≤±2mm), finely polished surfaces, strong seawater corrosion resistance, and support for custom cutting and welding services. We provide BV/DNV/ABS and other international certifications, with a quick response to custom needs.

5086 H111 Plate Alloy Composition

The main component of 5086 aluminum alloy is magnesium, which gives it high corrosion resistance, especially in seawater environments. The typical chemical composition includes:

- Magnesium (Mg): 3.5–4.5%

- Manganese (Mn): 0.2–0.7%

- Chromium (Cr): 0.05–0.25%

- Copper (Cu): ≤0.10%

- Iron (Fe): ≤0.5%

- Silicon (Si): ≤0.4%

- Titanium (Ti): ≤0.15%

- Zinc (Zn): ≤0.25%

- Others: each ≤0.05%, total ≤0.15%

- Balance: Aluminum (Al)

This composition ensures high strength and excellent corrosion resistance in marine environments.

5086 H111 Plate Mechanical Properties

The H111 temper indicates that the alloy has been strain-hardened, with a lower strength than the H32/H34 temper, achieving a balance between strength and ductility. Typical mechanical properties include:

- Tensile Strength: 260–300 MPa

- Yield Strength: 120–200 MPa

- Elongation: 12–20% (indicating good ductility)

- Hardness: approximately 60–75 Brinell Hardness (HB)

Note: The strength of H111 is lower than that of H32/H34, but its formability is better.

These properties make 5086-H111 aluminum suitable for applications that require moderate strength and good formability.

5086 H111 Plate Features

- Corrosion Resistance: Excellent performance in marine/coastal environments; resistant to seawater, chemicals, and industrial environments.

- Weldability: Easily welded using TIG, MIG, or resistance welding; good performance after welding.

- Formability: Due to the stable state of H111, it is suitable for bending, rolling, or forming.

- Non-heat-treatable: Strengthened only by strain hardening.

5086 H111 Plate Corrosion Resistance

5086 aluminum exhibits outstanding corrosion resistance, especially in marine environments. Its high magnesium content enhances its resistance to seawater corrosion, making it an ideal choice for shipbuilding and other marine applications.

5086 aluminum can withstand seawater erosion without losing strength, making it the preferred choice for shipbuilding and other maritime applications.

5086 H111 Plate Weldability and Formability

- The H111 temper ensures a balance between strength and formability.

- 5086 H111 can be easily welded using traditional methods such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding.

- 5086 H111 is also suitable for other forming processes, such as bending and stamping.

This gives it a broad range of manufacturing capabilities, making it ideal for applications that require both structural strength and ease of processing.

5086 H111 Plate Applications

5086-H111 aluminum plate is commonly used in:

- Marine Industry: Hull structures, decks, inland waterway vessels, yachts, and other components exposed to seawater.

- Transportation: Vehicle body and structural parts, C82 coal trucks, tankers, and other special vehicles.

- Construction: Structural components in buildings and infrastructure.

- Aerospace: Aircraft parts that require medium strength and corrosion resistance.

- Industrial: Pressure vessels, storage tanks, chemical processing equipment.

Haomei Aluminum 5086 H111 Plate Supply

5086 H111 aluminum plates are available in various thicknesses and sizes, typically ranging from 0.12 mm to 260 mm in thickness, with lengths up to 8000 mm. Surface treatments include brushed, polished, anodized, etc., depending on the specific requirements of the application.

5086 H111 Aluminum Plate Standards and Specifications

- ASTM B209: Aluminum plate/sheet standard.

- EN 485: European standard for semi-finished aluminum products.

- AMS 4026: Aerospace material specification.

- MIL-S-24149/2: Military standard for marine applications.

5086 H111 Aluminum Plate Surface Treatments

5086 H111 aluminum plates can be treated with various surface treatments based on application needs, including brushed, polished, and anodized finishes. These treatments not only enhance the material's appearance but also improve its corrosion resistance.

5086 H111 aluminum plate is a versatile, durable, and corrosion-resistant material commonly used in marine, transportation, and structural applications. Its balance of strength, corrosion resistance, and ease of processing makes it the material of choice for industries that require exposure to harsh environments.

Whether used in shipbuilding, automotive, or aerospace, 5086-H111 delivers excellent performance in demanding conditions.

Comparison of 5086 H111 Plate with Similar Alloys

- 5083 vs 5086: 5083 has a higher magnesium content (4.0-4.9%), resulting in higher strength but slightly lower corrosion resistance.

- 5052 vs 5086: 5052 has a lower magnesium content (2.2-2.8%), leading to lower strength but better formability.

Why Choose 5086 H111?

It is ideal for applications that require medium strength, excellent corrosion resistance, and ease of processing, especially in marine or corrosive environments. Its H111 temper provides great versatility in forming and welding, without compromising durability.

5086 H111 Plate Processing Notes

- Processing: Use sharp tools and lubricants; chips may appear as stringy.

- Annealing: H111 does not require annealing; avoid excessive cold working to prevent cracking.

- Surface Treatment: Usually supplied with a rolled surface; anodizing or painting can enhance appearance.

Recommended for you

-

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

As a direct manufacturer of 5086 Aluminum Sheet, we offer marine-grade aluminum plates that meet ASTM B209/EN 485 standards, featuring excellent seawater corrosion resistance and weldability.

-

As a professional aluminum plate manufacturer, we offer high-performance 5086 H116 aluminum alloy plates in a variety of specifications to meet the lightweight and industrial requirements of hulls.

-

As a leading manufacturer of aluminum alloys, we specialize in supplying 5086 H32 aluminum plate, ideal for harsh marine, industrial, and structural applications.

Other content readers are interested in

-

5086 marine grade aluminium checkered tread plate sheet

5086 marine grade aluminum checkered tread plate sheet has higher strength and corrosion resistance than 5052 and 5083 plates, making it ideal for many marine and marine applications.

-

5059 5086 Marine Grade Aluminum Bars

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

-

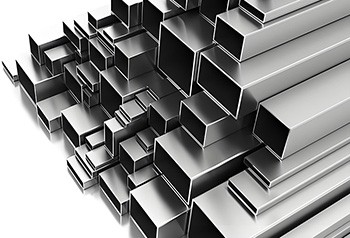

As a professional manufacturer of 5086 aluminum tubes, we offer seamless cold drawn aluminum tubes that comply with ASTM B210/B221 standards, with material strengthened by magnesium alloys, combining high strength and excellent seawater corrosion resistance.

-

5086 Aluminum Round Tubes and Pipes

As a professional aluminum alloy tube manufacturer, we offer 5086 aluminum alloy seamless round tubes, produced using high-precision cold drawing processes, conforming to international standards such as ASTM B210.

-

As a professional aluminum material manufacturer, we offer high-quality 5086 aluminum alloy square tubes, specifically designed for ships, marine engineering, and high-corrosion environments.

-

5086 Aluminum Drawn Seamless Pipe

As a leading manufacturer of precision aluminum products, we specialize in producing 5086 Aluminum Drawn Seamless Pipes designed for harsh environments.

-

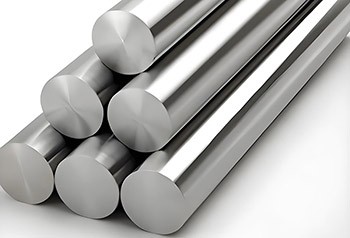

5086 aluminum alloy round bars achieve high strength through cold mechanical processing, offering excellent seawater corrosion resistance and weldability. They are specifically designed for shipbuilding, marine engineering, and transportation equipment.

-

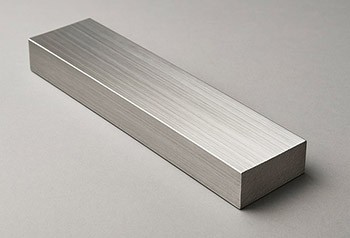

Professional production of 5086 aluminum flat bars, complete product specifications, direct sale from the manufacturer, favorable prices, strict quality control to ensure compliance with ASTM, EN, and other international standards.

-

As a professional aluminum alloy material manufacturer, we offer 5086 H111 aluminum alloy round bars, specially designed for harsh environments, suitable for shipbuilding, marine engineering, and industrial structural fields.

-

As a professional 5086 H32 pipe manufacturer, we provide high-performance, seawater corrosion-resistant customized pipe products, combining excellent strength and lightweight properties. Non-standard size processing is supported, and products are tested according to ISO certification and ASTM/EN standards.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

More content of interest to readers

What is the difference between 5086 and 6061 aluminum? 5086 H32 vs H116 What is 5086 grade aluminum? 5086 Aluminum vs 5052 5086 Aluminum vs. 5456 Aluminum 5086 and 5083 Aluminum Materials in Shipbuilding

Tags: Marine Aluminum 5086