5086 H32 Aluminum Plate

5086 H32 aluminum plate belongs to the aluminum-magnesium alloy (5xxx series), with "H32" indicating a strain-hardened and partially annealed condition. This condition balances the material's strength and formability through a combination of cold working and annealing processes.

5086-H32 aluminum plate is a high-strength, corrosion-resistant material primarily used for marine and structural applications. The "H32" condition signifies that the alloy has undergone strain hardening and stabilization treatment, resulting in a balance between strength and formability.

5086 H32 is a high-strength aluminum-magnesium alloy plate known for its excellent corrosion resistance, weldability, and moderate formability.

Haomei Aluminum, as a leading aluminum alloy manufacturer, specializes in supplying 5086 H32 aluminum plate, suitable for demanding marine, industrial, and structural applications. Our 5086 H32 aluminum plates combine exceptional corrosion resistance (especially in seawater environments), high strength, and excellent weldability, making them the preferred choice for shipbuilding, offshore platforms, and chemical storage solutions.

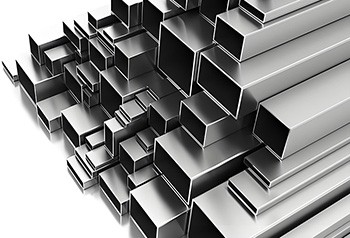

5086 H32 Aluminum Plate Specifications and Forms

- Plate Thickness: Ranges from thin plates (0.1–10mm) to thick plates (10–650mm)

- Forms: In addition to plates, custom processed products such as aluminum tubes and bars are also available

5086 H32 Aluminum Plate Standards and Certifications

- ASTM B209: Aluminum plate/sheet specification

- EN 485: European standard for aluminum plates

- AMS 4025: Aerospace material specification (for reference)

5086 H32 Aluminum Plate Properties

- High Strength and Durability: 5086 H32 is renowned for its high strength and excellent performance in seawater and industrial chemicals, making it ideal for marine environments.

- Corrosion Resistance: The magnesium content (3.5–4.5%) provides excellent corrosion resistance, particularly in seawater environments. It is resistant to stress corrosion cracking (the H32 stabilization treatment reduces residual stress).

- Weldability: The alloy is easy to weld, but due to its high magnesium content, extra care should be taken during welding to avoid cracking.

- Non-Heat-Treatable: Strength comes primarily from strain hardening (work hardening), not heat treatment.

- Formability: Medium; suitable for bending and forming, but its ductility is not as high as in annealed conditions (e.g., H111).

- Machinability: Average; due to the sticky nature of chips, sharp tools and lubrication are necessary.

5086 H32 Aluminum Plate Advantages

- Corrosion Resistance: Excellent performance in marine and other harsh environments, making it an ideal choice for marine and coastal structures.

- Strength: High strength in both rolled and extruded forms, providing structural integrity for applications.

- Versatility: Its versatility allows for a wide range of applications from marine industry to aerospace.

- Weldability: Excellent arc welding performance, suitable for complex structural welding.

- Machinability: Supports secondary processing such as cutting and bending, adaptable to diverse needs.

This material stands out for its overall performance, widely used in industrial scenarios requiring high corrosion resistance and moderate strength, and it can meet various design requirements by adjusting supply conditions.

5086 H32 Aluminum Plate Mechanical Properties

- Ultimate Tensile Strength: Approximately 47, 000 psi

- Yield Strength: Approximately 28, 000 psi

- Elongation at Break: Typically 10-12%

- Brinell Hardness: Approximately 87

- Modulus of Elasticity: 10, 300 ksi

- Shear Strength: Approximately 27, 000 psi

- Fatigue Strength: Approximately 21, 800 psi

These properties make 5086-H32 aluminum material suitable for applications that require moderate strength and good formability.

5086 H32 Aluminum Plate Physical Properties

- Density: 2.66–2.71 g/cm³

- Melting Range: 570–640°C (1, 058–1, 184°F)

- Thermal Conductivity: 125 W/m·K

- Electrical Conductivity: ~29% IACS (International Annealed Copper Standard)

- Coefficient of Thermal Expansion: 23.8 µm/m·°C (20–100°C)

5086 H32 Aluminum Plate Corrosion Resistance

5086-H32 aluminum material has excellent performance in seawater and marine environments, making it an ideal choice for hulls, ship structures, and other marine applications.

5086 H32 Aluminum Plate Manufacturing and Machinability

This alloy is not heat-treatable but can be strengthened through strain hardening. It is easy to weld, machine, and form. However, due to its high magnesium content, special measures may be required during welding to prevent cracking.

- Machining: While 5086 is fairly easy to machine due to its strength and hardness, care must be taken to avoid work hardening.

- Welding: Using 5356 or 5183 filler rods achieves the best results. Standard welding processes such as MIG or TIG can be used, but due to the high magnesium content, precautions must be taken to prevent cracking. Preheating before welding is sometimes recommended.

- Forming: The alloy is easy to form, but as the material hardens (strain hardening), forming difficulty increases. Excessive cold working should be avoided, and annealing is recommended if severe forming is required.

- Surface Treatment: Typically undergoes a smooth finish. Anodizing or painting can enhance aesthetics and protection.

5086 H32 Aluminum Plate Chemical Composition (Weight Percentage)

- Aluminum (Al): Remainder

- Magnesium (Mg): 3.5–4.5%

- Manganese (Mn): 0.2–0.7%

- Chromium (Cr): 0.05–0.25%

- Zinc (Zn): Maximum 0.25%

- Silicon (Si): Maximum 0.4%

- Iron (Fe): Maximum 0.5%

- Copper (Cu): Maximum 0.1%

- Titanium (Ti): Maximum 0.15%

5086 H32 Aluminum Plate Applications

- Marine Environment: Suitable for hulls, ship structures, and other marine parts requiring seawater corrosion resistance.

- Pressure Vessels: Used for manufacturing tanks, pipelines, and other high-strength applications that need to withstand external pressure.

- Low-Temperature Equipment: Due to its toughness and low-temperature strength, it is suitable for low-temperature applications.

- Oil and Gas Industry: Used for pipes, tanks, and structures exposed to harsh environments.

- Structural Components: Commonly used in marine, aerospace, and transportation fields to manufacture structural components that require strength and corrosion resistance.

- Armor Plate: Due to its strength and durability, 5086 is also used in military and armored applications.

Structural components requiring medium strength and excellent corrosion resistance.

5086 H32 Aluminum Compared to Similar Alloys

- 5083 H32: Slightly higher strength, but poorer formability.

- 5052 H32: Lower strength, but better formability.

- 6061 T6: Heat-treatable alloy, higher strength, but poorer seawater corrosion resistance.

5086 H32 Aluminum Limitations

Not heat treatable; strength depends on work hardening.

Avoid prolonged exposure to temperatures above 65°C (149°F) to prevent softening.

5086 H32 aluminum plate is an ideal choice for marine and structural applications that require a balance of strength, corrosion resistance, and weldability. Its H32 condition ensures stable performance in harsh environments over extended periods.

Why Choose Our 5086 H32 Aluminum Plate?

- Certified Quality: Complies with ASTM B209 and EN 485 standards.

- Custom Sizes: Offers customized thickness and dimensions to meet project specifications.

- Durability: Stable H32 temper process ensures long-lasting performance under pressure.

- Fast Delivery: Supports bulk orders with competitive pricing and reliable logistics.

Trust in our expertise in aluminum manufacturing, and we can provide plates that perform excellently in harsh environments while reducing lifecycle costs. Request a quote for corrosion-resistant, high-performance 5086 H32 aluminum solutions now!

Recommended for you

-

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

As a direct manufacturer of 5086 Aluminum Sheet, we offer marine-grade aluminum plates that meet ASTM B209/EN 485 standards, featuring excellent seawater corrosion resistance and weldability.

-

As a professional aluminum plate manufacturer, we offer high-performance 5086 H116 aluminum alloy plates in a variety of specifications to meet the lightweight and industrial requirements of hulls.

-

Our company specializes in the production of 5086 H111 medium-thick aluminum plates, with a finely polished surface and strong resistance to seawater corrosion. We offer customized cutting and welding services, and provide international certifications such as BV/DNV/ABS, with quick response to custom needs.

Other content readers are interested in

-

5086 marine grade aluminium checkered tread plate sheet

5086 marine grade aluminum checkered tread plate sheet has higher strength and corrosion resistance than 5052 and 5083 plates, making it ideal for many marine and marine applications.

-

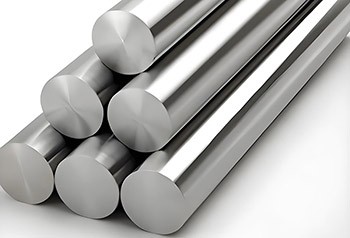

5059 5086 Marine Grade Aluminum Bars

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

-

As a professional manufacturer of 5086 aluminum tubes, we offer seamless cold drawn aluminum tubes that comply with ASTM B210/B221 standards, with material strengthened by magnesium alloys, combining high strength and excellent seawater corrosion resistance.

-

5086 Aluminum Round Tubes and Pipes

As a professional aluminum alloy tube manufacturer, we offer 5086 aluminum alloy seamless round tubes, produced using high-precision cold drawing processes, conforming to international standards such as ASTM B210.

-

As a professional aluminum material manufacturer, we offer high-quality 5086 aluminum alloy square tubes, specifically designed for ships, marine engineering, and high-corrosion environments.

-

5086 Aluminum Drawn Seamless Pipe

As a leading manufacturer of precision aluminum products, we specialize in producing 5086 Aluminum Drawn Seamless Pipes designed for harsh environments.

-

5086 aluminum alloy round bars achieve high strength through cold mechanical processing, offering excellent seawater corrosion resistance and weldability. They are specifically designed for shipbuilding, marine engineering, and transportation equipment.

-

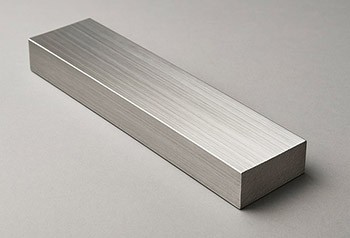

Professional production of 5086 aluminum flat bars, complete product specifications, direct sale from the manufacturer, favorable prices, strict quality control to ensure compliance with ASTM, EN, and other international standards.

-

As a professional aluminum alloy material manufacturer, we offer 5086 H111 aluminum alloy round bars, specially designed for harsh environments, suitable for shipbuilding, marine engineering, and industrial structural fields.

-

As a professional 5086 H32 pipe manufacturer, we provide high-performance, seawater corrosion-resistant customized pipe products, combining excellent strength and lightweight properties. Non-standard size processing is supported, and products are tested according to ISO certification and ASTM/EN standards.

-

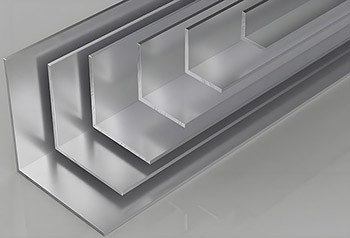

As a leading supplier of 5086 aluminum alloy angles, we offer a full range of sizes in 5086-H111 structural angles, suitable for marine ladders, pressure vessels, and transportation equipment.

-

As a professional aluminum material manufacturer, we provide 5086 H111 aluminum alloy angles, combining high strength and excellent corrosion resistance, especially suitable for the marine, offshore engineering, and industrial structural fields.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

More content of interest to readers

What is the difference between 5086 and 6061 aluminum? 5086 H32 vs H116 What is 5086 grade aluminum? 5086 Aluminum vs 5052 5086 Aluminum vs. 5456 Aluminum 5086 and 5083 Aluminum Materials in Shipbuilding

Tags: Marine Aluminum 5086