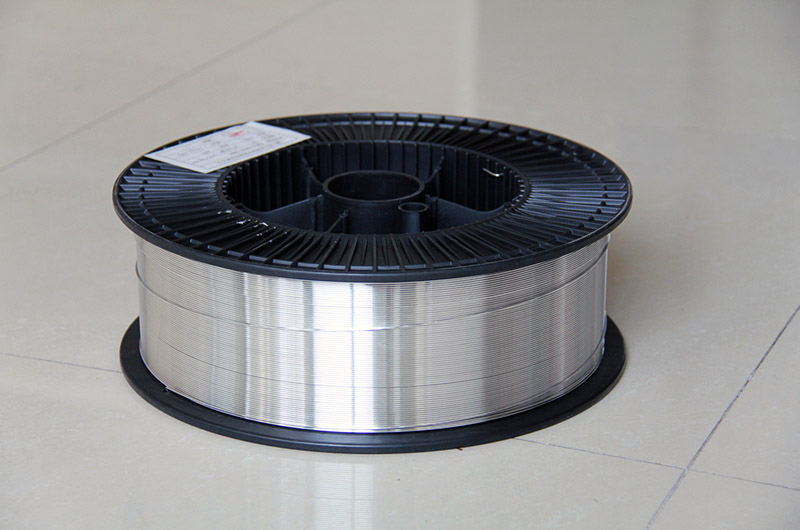

ER5183 Marine grade aluminum welding wire

ER5183 is a common wire used for welding marine grade aluminum alloys. The "ER" prefix indicates it is a welding rod or filler rod, and "5183" designates the specific alloy.

5183 aluminum welding wire is an aluminum-magnesium welding wire with a magnesium content of close to 5% and a higher manganese content. Used for welding with high magnesium content and high tensile strength requirements (for example, the tensile strength is above 276MPa).

5183 aluminum filler is used to increase the strength of alloys such as 5086, compared to 5356. It is usually used for welding marine parts, low-temperature materials, and welding between aluminum alloys such as 5083, 5086, 5456, or with 5052, 5652, and 5056.

Low-temperature aluminum welding wire 5356 can weld white metals, including aluminum, aluminum alloys, cast aluminum, aluminum-magnesium alloys, and dissimilar metal welding between the above metals. Suitable for all-round welding by entry-level welding operators, requiring only a small heating unit.

Marine-grade aluminum alloys, such as those used in shipbuilding or other marine applications, often require welding materials with excellent corrosion resistance and mechanical properties. ER5183 is well suited for this application because of its good strength, weldability and corrosion resistance, especially in marine environments where there is frequent exposure to salt water and other corrosive elements.

Why choose 5183 aluminum alloy for marine aluminum welding wire?

Aluminum alloy 5183 is often chosen for marine aluminum welding because it has special properties suitable for marine applications:

- 1. Corrosion resistance: Marine environments expose metals to corrosive elements such as salt water, which can cause metal degradation over time. Aluminum alloy 5183 offers excellent corrosion resistance, making it ideal for marine applications with frequent exposure to salt water.

- 2. High strength: 5183 aluminum alloy has good mechanical properties, including high strength. This strength is critical to withstand the stresses and strains experienced in the marine environment, particularly in structures such as hulls and ships.

- 3. Weldability: 5183 aluminum alloy is known for its excellent weldability, which is crucial for manufacturing marine structures and repairing aluminum parts on ships. Welding wire made from 5183 alloy produces high-quality welds with good strength and corrosion resistance.

- 4. Anodizing ability: Anodizing is a common surface treatment method used in marine applications to improve corrosion resistance and enhance appearance. Aluminum alloy 5183 can be effectively anodized, providing additional protection against corrosion in marine environments.

The combination of corrosion resistance, high strength, weldability and anodizing capabilities make 5183 aluminum alloy the first choice for marine aluminum welding applications.

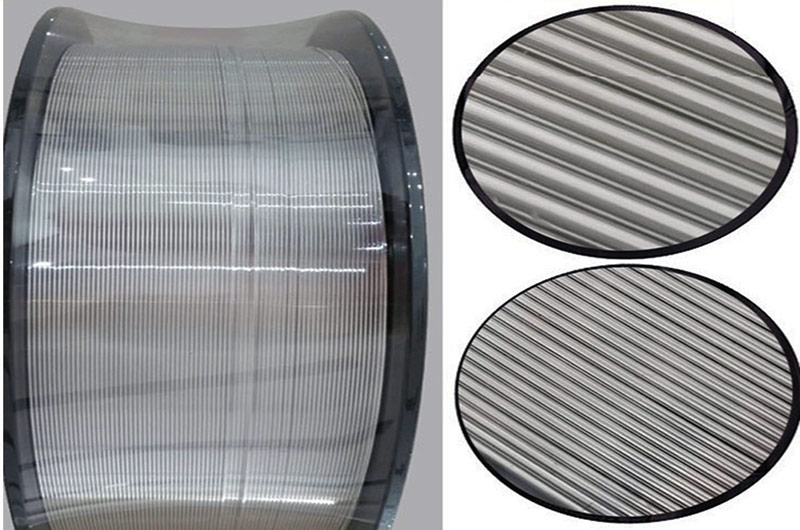

ER5183 Marine grade aluminum welding wire features

- Chemical composition: ER5183 welding wire contains magnesium, manganese and other elements, and is suitable for welding materials with high magnesium content in aluminum alloys.

- Corrosion resistance: ER5183 welding wire has good corrosion resistance and can maintain the stability of the weld in harsh environments.

- High strength: Aluminum alloy welds have high strength after welding and are suitable for tank truck parts that require high welding strength.

- Welding performance: ER5183 welding wire has good welding performance, providing good fluidity and weld appearance quality.

Specification parameters of ER5183 Marine grade aluminum welding wire

| Alloy | 5183, ER5183 | |||||

| Category | Straight wire | Reel-mounted wire | Hollow coil wire | |||

| Dimensions mm | Diameter | 1.60, 2.00, 2.40, 3.00, 3.20, 4.00, 5.00 | 0.80, 1.00, 1.20, 1.60 | 2.40, 3.00, 3.20, 4.00 | ||

| Length | 1000 | - | - | |||

| Coil Diameter | - | 100 | 200 | 270, 300 | - | |

| Net weight (per box or roll) kg | 2.5, 5, 10, 20 | 0.45 | 2.0, 2.5 | 5, 6, 7 | 5, 8, 10, 12, 15 | |

ER5183 Marine grade aluminum welding wire Chemical Composition

| Alloy | 5183 |

| Si | ≤0.4 |

| Fe | ≤0.4 |

| Cu | ≤0.10 |

| Mn | 0.5-1.0 |

| Mg | 4.3-5.2 |

| Cr | ≤0.25 |

| Zn | ≤0.25 |

| Ti | ≤0.15 |

| Al | Remainder |

ER5183 Marine grade aluminum welding wire Physical properties

| Alloy | 5183 |

| Melting range | 1075-1180°F |

| Conductivity | 16-19Ω·m/mm2 |

| Density | 2.66g/mm2 |

| Corrosion resistance | A(Gen)A(SCC) |

| Thermal expansion coefficient (20℃~300℃) | 23.7×10¯⁶/K |

| Thermal conductivity (20℃) | 110-120W/m.k |

ER5183 marine grade aluminum welding wire applications

ER5183 welding wire is mainly used in shipbuilding, ship repair, offshore structures and other marine-related industries that require welding of aluminum parts. It has good weldability and high strength and is suitable for joining various marine grade aluminum alloys.

- Hull Construction: Aluminum plates or profiles are welded together to form the hulls of boats and other watercraft.

- Marine Structures: Fabrication and repair of a wide range of aluminum components used in marine structures such as docks, bridge piers and offshore platforms.

- Shipbuilding: Joining aluminum plates and components to build ships.

- Marine Equipment: Manufacture and repair of aluminum components used in marine equipment, such as propellers, masts and rigging.

- Marine Tank Fabrication: Welded aluminum tanks used to store fuel, water or other liquids on ships.

ER5183 welding wire is critical to ensuring strong and durable welds in marine applications where corrosion resistance and high strength are key requirements.

5183 aluminum alloy welding wire can be used for welding 5654 and 5083 aluminum plates, and has excellent seawater corrosion resistance and low temperature performance. The weld seam is white after anodization, providing a good color match for the welded joint. Used for the welding of aluminum alloys related to ship structures, offshore platforms, cryogenic vessels, railway locomotives, and the automotive industry.

Marine aluminum products you may be interested in

-

ER5356 Marine grade aluminum welding wire

ER5356 Marine Grade Aluminum Welding Wire is a high quality welding consumable specifically designed to handle marine welding, providing excellent corrosion resistance, strength and weldability.