5383 H116 Aluminum

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

5383-H116 aluminum is the H116 temper of the 5383 aluminum alloy, a state achieved through specific heat treatment and processing to enhance the material's properties. The primary purpose of the H116 temper is to ensure better corrosion resistance of the aluminum alloy in marine environments while maintaining certain mechanical strength.

5383-H116 aluminum is an alloy primarily designed for marine applications. In the H116 temper, it has enhanced corrosion resistance, particularly to seawater corrosion, through appropriate heat treatment and cold processing. Although its strength and fatigue strength are lower, it performs excellently in resisting corrosion and handling light loads, making it suitable for use in ships and marine structures.

5383-H116 Aluminum Properties

Temper and Hardness

The H116 temper is the result of cold working the 5383 aluminum alloy after heat treatment, aimed at achieving specific mechanical properties through moderate stretching and processing of the material.

The 5383 aluminum alloy in the H116 temper has lower hardness and strength but exhibits superior corrosion resistance compared to other aluminum alloys, especially in resisting seawater corrosion.

Intergranular Corrosion and Exfoliation Corrosion

In the H116 temper, the intergranular corrosion and exfoliation corrosion characteristics of the aluminum alloy are treated to effectively prevent the spread of corrosion when exposed to marine environments for extended periods.

Specific treatments control corrosion at the grain boundaries through minor corrosion action, which helps extend the material's lifespan in extreme environments.

Strength and Toughness

5383-H116 aluminum has moderate tensile strength and yield strength, sufficient for general marine applications, such as hull structures and some external parts of ships.

The material has moderate toughness, making it suitable for applications where extreme strength is not required.

Corrosion Resistance

The greatest advantage of 5383-H116 aluminum is its excellent corrosion resistance, particularly its ability to resist saltwater corrosion in marine environments. This makes it widely used in the construction of ships, offshore platforms, and other marine structures.

The corrosion resistance of this alloy is stronger than that of other aluminum alloys, making it suitable for long-term exposure to water and salt-rich environments.

5383 H116 Aluminum Mechanical Properties

| Property | 5383-H116 Aluminum |

| Brinell Hardness | 90 |

| Elastic (Young's, Tensile) Modulus, x 10⁶ psi | 9.9 |

| Elongation at Break, % | 12 |

| Fatigue Strength, x 10³ psi | 25 |

| Poisson's Ratio | 0.33 |

| Shear Modulus, x 10⁶ psi | 3.7 |

| Shear Strength, x 10³ psi | 30 |

| Tensile Strength: Ultimate (UTS), x 10³ psi | 51 |

| Tensile Strength: Yield (Proof), x 10³ psi | 35 |

5383 H116 Aluminum Thermal Properties

| Property | 5383-H116 Aluminum |

| Latent Heat of Fusion, J/g | 390 |

| Maximum Temperature: Corrosion, °F | 150 |

| Maximum Temperature: Mechanical, °F | 400 |

| Melting Completion (Liquidus), °F | 1200 |

| Melting Onset (Solidus), °F | 1010 |

| Specific Heat Capacity, BTU/lb-°F | 0.22 |

| Thermal Conductivity, BTU/h-ft-°F | 72 |

| Thermal Expansion, µm/m-K | 24 |

5383 H116 Aluminum Electrical Properties

| Property | 5383-H116 Aluminum |

| Electrical Conductivity: Equal Volume, % IACS | 29 |

| Electrical Conductivity: Equal Weight (Specific), % IACS | 97 |

5383 H116 Aluminum Alloy Composition

| Element | Composition Range (%) |

| Aluminum (Al) | 92.0 to 95.3 |

| Magnesium (Mg) | 4.0 to 5.2 |

| Manganese (Mn) | 0.7 to 1.0 |

| Zinc (Zn) | 0.0 to 0.4 |

| Silicon (Si) | 0.0 to 0.25 |

| Chromium (Cr) | 0.0 to 0.25 |

| Iron (Fe) | 0.0 to 0.25 |

| Zirconium (Zr) | 0.0 to 0.2 |

| Copper (Cu) | 0.0 to 0.2 |

| Titanium (Ti) | 0.0 to 0.15 |

| Residuals | 0.0 to 0.15 |

5383 H116 Aluminum Applications

5383 H116 aluminum alloy is widely used in marine and shipbuilding fields due to its excellent seawater corrosion resistance and light load-bearing capacity, especially in structures that are exposed to marine environments for extended periods but do not bear extreme strength loads.

| Application Field | Description |

| Shipbuilding | 5383-H116 aluminum alloy is widely used in external parts of ships, such as hulls, hull structures, and decks. These parts are exposed to a saltwater environment and must have corrosion resistance. The H116 aluminum alloy provides sufficient corrosion resistance, making it suitable for components with relatively low strength requirements, ensuring the long-term use and structural integrity of the ship. |

| Marine Structures | In marine structures, 5383-H116 aluminum alloy is primarily used in components exposed to seawater, such as buoys, offshore platform support parts, and floating structures. These structures need to resist corrosion in the marine environment and typically bear relatively light loads, so the strength and corrosion resistance of the H116 aluminum alloy make it ideal for these applications. |

| Seawater Pipelines | Due to its excellent corrosion resistance, 5383-H116 aluminum alloy is also used in the manufacture of seawater pipelines, particularly those in seawater transport systems. These pipelines need to operate in marine environments for long periods, and the corrosion resistance of H116 aluminum alloy ensures the long-term stability and reliability of the pipelines. |

| Light-load Structures | 5383-H116 aluminum alloy is suitable for light-load applications, such as smaller marine engineering structures, equipment supports, and frame structures. These structures typically require a certain amount of strength but do not need to withstand extreme pressure and weight loads. The strength and corrosion resistance of H116 aluminum alloy make it an ideal choice for these applications. |

| External Parts of Hulls | As external components of the hull, 5383-H116 aluminum alloy is extensively used in areas such as hulls, shells, and decks. Since these parts are exposed to seawater for long periods, corrosion resistance is a key requirement, and the H116 aluminum alloy can effectively resist seawater corrosion while providing reliable performance without bearing excessive loads. |

5383-H116 aluminum alloy, with its excellent corrosion resistance and moderate strength, is widely used in shipbuilding, marine structures, and light-load marine engineering. It is an ideal material choice, particularly for components exposed to seawater environments and not subjected to extreme strength loads, such as external hulls, decks, frame structures, and seawater pipelines.

Recommended for you

-

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

Other content readers are interested in

-

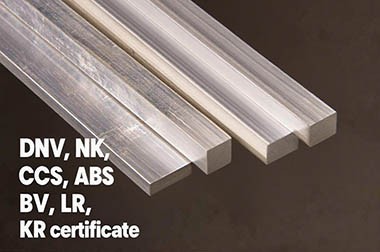

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 5383 Marine Grade Aluminium Hex Bar

The 5083 and 5383 aluminum hex bars produced by Haomei comply with multiple international and industry standards to ensure product quality and performance meet global application requirements.

-

5083 5383 O H112 Marine Aluminum Square Bar

Haomei Aluminum is capable of producing marine-grade 5083 and 5383 aluminum square bars in O and H112 tempers, certified by major international classification societies including DNV, NK, CCS, ABS, BV, LR, and KR.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

More content of interest to readers

5383-O Aluminum vs. 5456-O Aluminum 5383-H32 Aluminum vs. 5456-H32 Aluminum 5383-H111 Aluminum vs. 5456-H111 Aluminum 5383-H116 Aluminum vs. 5383-H321 Aluminum 5383 Aluminum vs. 5456 Aluminum 5383-H112 Aluminum vs. 5456-H112 Aluminum 5383 Aluminum Hot Rolling Process 5083 vs 5383 Aluminum Alloys: Which is Better for Your Project?

You might be interested in: Marine Aluminum 5383 5 Series Marine Aluminum Aluminum for Boat Aluminum for Shipbuilding