5383 O Aluminum

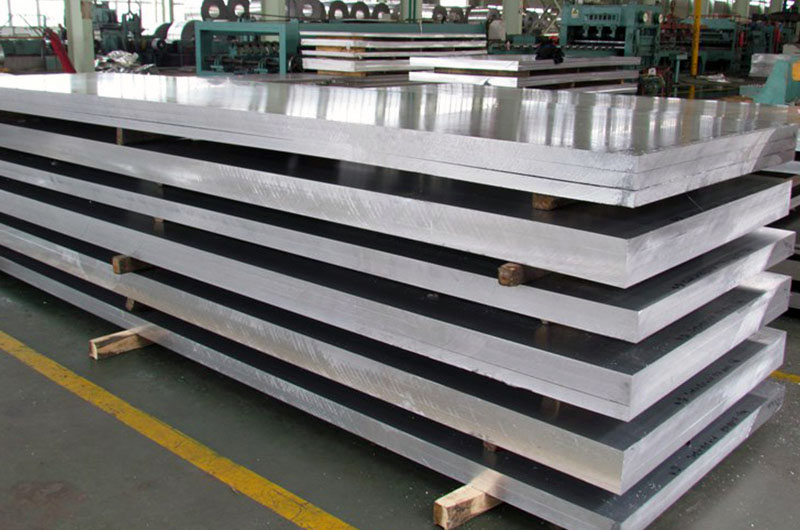

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments. It is commonly used in applications requiring good corrosion resistance and adequate strength, especially suitable for ships and marine structures.

5383-O aluminum alloy has good corrosion resistance and adequate mechanical properties, making it suitable for marine environments, transportation vehicles, storage tanks, and other fields. Although its strength is relatively low, its excellent ductility and machinability make it ideal for applications requiring high formability and corrosion resistance.

5383 O Aluminum Mechanical Properties

| Property | 5383-O Aluminum |

| Brinell Hardness | 85 |

| Elastic (Young's, Tensile) Modulus, GPa | 68 |

| Elongation at Break, % | 15 |

| Fatigue Strength, MPa | 160 |

| Poisson's Ratio | 0.33 |

| Shear Modulus, GPa | 26 |

| Shear Strength, MPa | 190 |

| Tensile Strength: Ultimate (UTS), MPa | 310 |

| Tensile Strength: Yield (Proof), MPa | 150 |

5383 O Aluminum Thermal Properties

| Property | 5383-O Aluminum |

| Latent Heat of Fusion, J/g | 390 |

| Maximum Temperature: Corrosion, °C | 65 |

| Maximum Temperature: Mechanical, °C | 200 |

| Melting Completion (Liquidus), °C | 650 |

| Melting Onset (Solidus), °C | 540 |

| Specific Heat Capacity, J/kg-K | 900 |

| Thermal Conductivity, W/m-K | 130 |

| Thermal Expansion, µm/m-K | 24 |

5383 O Aluminum Electrical Properties

| Property | 5383-O Aluminum |

| Electrical Conductivity: Equal Volume, % IACS | 29 |

| Electrical Conductivity: Equal Weight (Specific), % IACS | 97 |

5383 O Aluminum Alloy Composition

| Element | 5383-O Aluminum |

| Aluminum (Al), % | 92 to 95.3 |

| Chromium (Cr), % | 0 to 0.25 |

| Copper (Cu), % | 0 to 0.2 |

| Iron (Fe), % | 0 to 0.25 |

| Magnesium (Mg), % | 4.0 to 5.2 |

| Manganese (Mn), % | 0.7 to 1.0 |

| Silicon (Si), % | 0 to 0.25 |

| Titanium (Ti), % | 0 to 0.15 |

| Zinc (Zn), % | 0 to 0.4 |

| Zirconium (Zr), % | 0 to 0.2 |

| Residuals, % | 0 |

5383 O Aluminum Applications

Marine Structures

5383-O aluminum alloy is widely used in marine structures, particularly in the manufacturing of ships and offshore platforms. Its excellent corrosion resistance makes it perform exceptionally well in corrosive environments such as seawater and salt mist, resisting oxidation and corrosion, thereby extending the lifespan of structural components.

- Shipbuilding: 5383-O aluminum alloy is used in structural components of ship hulls, external coverings, decks, bulkheads, and other areas. Its excellent corrosion resistance allows ships to be used in saltwater environments for extended periods, reducing maintenance costs and corrosive damage.

- Offshore Platforms: In offshore oil and gas platforms, marine wind power platforms, and other facilities, 5383-O aluminum alloy is used for structural supports and other parts that need to withstand seawater corrosion. Its lightweight and corrosion-resistant properties make it an ideal choice for marine environments, especially in applications exposed to seawater for extended periods.

- Underwater Equipment: This aluminum alloy can also be used in underwater equipment, such as the shells of underwater robots and detection devices, helping them maintain stable performance in long-term underwater environments.

Transportation

In the transportation sector, 5383-O aluminum alloy is commonly used in manufacturing structural components that require corrosion resistance and adequate strength. Due to its good ductility and corrosion resistance, this aluminum alloy is highly suitable for the manufacture of vehicles and other modes of transportation.

- Ships and Yachts: Used for manufacturing ship hull structures, shells, and components of ships and yachts. 5383-O aluminum alloy resists corrosion in seawater, reducing hull damage and maintenance costs, while maintaining good strength and durability.

- Public Transport Vehicles: In the manufacture of high-speed trains, subway cars, and other public transport vehicles, 5383-O aluminum alloy is used as the outer shell material for the car bodies, providing the advantage of lightweight construction while effectively preventing structural damage caused by moisture or corrosion.

- Automotive Manufacturing: Although 5383-O aluminum alloy has relatively low strength, it can still be used for certain automotive components that require corrosion resistance and do not bear heavy loads, such as car doors and window frames.

Storage Tanks and Pipelines

5383-O aluminum alloy is also widely used in liquid storage and transportation applications, particularly in environments where corrosion and seawater exposure are concerns. Due to its good corrosion resistance and adequate strength, 5383-O aluminum alloy is highly suitable for the following applications.

- Storage Tanks: Used for storing various liquids (such as oil, chemicals, beverages, etc.). The corrosion resistance of 5383-O aluminum alloy ensures that storage tanks are not damaged by the corrosive properties of the liquids over long-term use.

- Pipelines: In liquid transportation pipeline systems, particularly in offshore platforms and chemical factories, 5383-O aluminum alloy can be used as pipeline material. It can withstand high humidity and corrosive environments, while also being lightweight, reducing the load on the system.

- Liquid Containers: In addition to storage tanks and pipelines, 5383-O aluminum alloy can also be used to manufacture liquid containers, such as water tanks and oil tanks. Its corrosion resistance ensures the safety and stability of containers in harsh environments.

5383-O aluminum alloy, with its excellent corrosion resistance and good machinability, is an ideal material for marine structures, transportation, and liquid storage and pipeline transportation fields.

Recommended for you

-

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

Other content readers are interested in

-

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

More content of interest to readers

5383-O Aluminum vs. 5456-O Aluminum 5383-H32 Aluminum vs. 5456-H32 Aluminum 5383-H111 Aluminum vs. 5456-H111 Aluminum 5383-H116 Aluminum vs. 5383-H321 Aluminum 5383 Aluminum vs. 5456 Aluminum 5383-H112 Aluminum vs. 5456-H112 Aluminum 5383 Aluminum Hot Rolling Process 5083 vs 5383 Aluminum Alloys: Which is Better for Your Project?