5456 H111 Aluminum

5456 H111 aluminum is a forged 5000 series aluminum-magnesium alloy. "H111" indicates that the material has a strain hardening degree slightly lower than the H11 temper. This temper results in the material being unable to undergo additional strengthening through heat treatment – its strength comes entirely from controlled cold working. This alloy is known for its excellent corrosion resistance (even in marine environments), good weldability, and a balanced combination of strength and ductility.

5456 H111 aluminum is specifically designed for structural and marine applications, with the "H111" temper indicating it has undergone strain hardening and partial annealing treatment, balancing strength and formability. This alloy cannot be heat treated but gains strength through cold working, making it an ideal choice for environments requiring durability and corrosion resistance.

5456 H111 aluminum is an aluminum-magnesium alloy that combines strength, corrosion resistance, and workability. The H111 temper means it has minimal strain hardening, providing reliable performance for applications that require durability in corrosive or marine environments.

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion. Its characteristics and applications are determined by its treatment in the H111 condition.

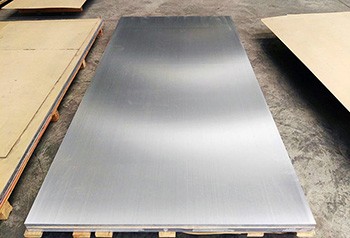

5456 H111 Aluminum Material

- Alloy Type: 5456 aluminum alloy belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, especially in seawater environments. Its primary alloying element is magnesium, with a typical magnesium content between 4.5% and 5.5%.

- Heat Treatment Condition: The H111 condition means that the aluminum alloy has undergone mild processing or annealing treatment. Compared to the H11 (1/8 hardness), the H111 has lower strength but better ductility. The alloy has moderate strength after strain hardening in the H111 condition, making it suitable for applications that require some formability but not high strength.

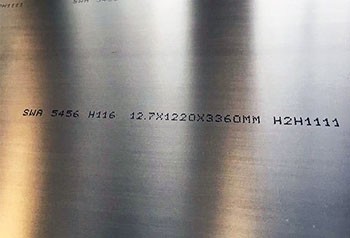

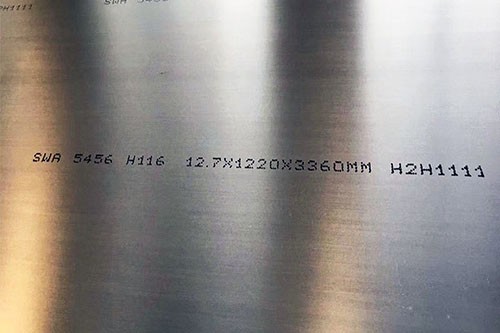

Haomei 5456 Aluminum Technical Specifications

Haomei Aluminum offers 5456 H111 plates, certified (e.g., DNV, ABS) and customized in size, for shipbuilding.

| Parameter | Details |

| Chemical Composition | Mg (4.7–5.5%), Mn (0.5–1.0%), Cr (0.05–0.20%), with trace Si, Fe, Cu, Zn. |

| Temper Options | O, H111, H112, H116, H321 (H111 common for beams and plates). |

| Dimensions | Beams: Up to 5" x 4.2" x 0.21" (Stock lengths: 12–40 ft). Plates: Thickness 3–50 mm, width ≤3600 mm. |

| Certifications | ASTM B928, EN573, DNV, ABS, CCS, LR, NK (ensuring marine-grade compliance). |

5456 H111 Aluminum Performance Characteristics

Mechanical Properties

- Strength: Compared to other heat-treated states of 5456 aluminum alloy, the strength of the H111 condition is lower. It is suitable for applications with lower mechanical performance requirements.

- Ductility: Due to the mild processing or annealing in the H111 state, 5456 aluminum has relatively high ductility, which gives it good formability.

- Hardness: The hardness of H111 is lower than that of other stronger states of aluminum alloys (such as H32, H116), and it is typically used in applications that do not require high hardness.

Corrosion Resistance

5456 aluminum alloy performs excellently in seawater or other corrosive environments. Due to its high magnesium content, it offers outstanding resistance to corrosion in marine environments, making it ideal for use in marine structures, ships, and offshore platforms.

Weldability

This aluminum alloy in the H111 condition has good weldability, making it suitable for structural construction using welding, which is commonly employed in shipbuilding and marine engineering.

Cold Workability

Strength is enhanced through cold working (such as rolling, extrusion), and customizable beams, plates, and complex shapes are available.

5456 H111 Aluminum Chemical Composition

The alloy’s composition (by weight percentage) typically falls within the following ranges:

- Aluminum (Al): 92.0 – 94.8%

- Magnesium (Mg): 4.7 – 5.5%

- Manganese (Mn): 0.5 – 1.0%

- Iron (Fe): Up to 0.4%

- Silicon (Si): Up to 0.25%

- Chromium (Cr): 0.05 – 0.2%

- Zinc (Zn): Up to 0.25%

- Titanium (Ti): Up to 0.2%

- Copper (Cu): Up to 0.1%

- Residuals: Up to 0.15%

The relatively high magnesium content is key to its strength and workability while also contributing to its excellent resistance to corrosion.

5456 H111 Aluminum Mechanical Strength

- Tensile Strength: 285–360 MPa (O/H111 temper)

- Yield Strength: 125–205 MPa (O/H111 temper)

- Elongation: ≥16% (annealed state), ensuring good plasticity.

5456 H111 Aluminum Advantages Over Similar Alloys

- Higher Strength: Superior to 5083 and 5086 alloys, suitable for heavy-duty marine structures.

- Cost-effective: Reduces shipbuilding costs by reducing weight and improving energy efficiency.

- Customizable: Offers custom sizes and tempers to meet specific project requirements.

5456 H111 Aluminum Applications

5456-H111 aluminum alloy is widely used for structural components that require good formability and moderate strength, particularly in marine environments.

Ship Structure

Hull and bottom materials: 5456 aluminum alloy is extensively used in the hull, bottom, and other components of ships exposed to seawater. Its corrosion resistance in seawater ensures that the ship's hull can maintain a longer service life in harsh marine environments.

Offshore Platforms

It is used in structural components for offshore platforms, including offshore drilling platforms, oil rigs, and offshore wind turbines. These structures are often exposed to highly corrosive marine environments, requiring materials with excellent corrosion resistance and adequate strength.

Underwater Components

Due to its excellent corrosion resistance, 5456 aluminum alloy in the H111 condition is also commonly used in underwater equipment and structural components, such as underwater pipelines, marine exploration equipment, and fishing equipment.

Other Light Structural Applications

In addition to the marine and shipbuilding fields, 5456-H111 aluminum alloy can also be used in other sectors where mechanical performance requirements are low but corrosion resistance is critical.

Haomei 5456 H111 Aluminum Product Forms

| Category | Product Form |

| Bar Products | 5456 H111 Flat Bar |

| 5456 H111 Half Round | |

| 5456 H111 Hexagon Bar | |

| 5456 H111 Octagonal Bar | |

| 5456 H111 Round Bar | |

| 5456 H111 Square Bar | |

| Structurals | 5456 H111 Shapes (Extruded) |

| Structurals | 5456 H111 Angle |

| 5456 H111 Angle (Unequal Leg) | |

| 5456 H111 Beams (H) | |

| 5456 H111 Beams (I) | |

| 5456 H111 Channel | |

| 5456 H111 Tees | |

| 5456 H111 Zees | |

| Tubular Products | 5456 H111 Pipe (Seamless) |

| 5456 H111 Tube (Rectangular) | |

| 5456 H111 Tube (Square) |

Haomei 5456 H111 Aluminum Bar Products

| Product Form | Description |

| 5456 H111 Aluminum Flat Bar | 5456 H111 flat bars are widely used in the frame and support structures of shipbuilding, offshore platforms, and underwater equipment. Its excellent corrosion resistance makes it durable in marine environments, suitable for making hull edges, beams, and other load-bearing components. |

| 5456 H111 Aluminum Half Round | 5456 H111 half-round bars are commonly used in collision protection devices or guiding structures on ships and offshore platforms. They can serve as auxiliary support parts for the ship's hull, ensuring that the structure has the necessary elasticity and corrosion resistance in marine environments. |

| 5456 H111 Aluminum Hexagon Bar | 5456 H111 hexagonal bars are commonly used as fasteners, connectors, and other structural components in the marine industry, particularly in shipbuilding and offshore platform structures. Its excellent corrosion resistance and strength make it a common choice in seawater and other corrosive environments. |

| 5456 H111 Aluminum Octagonal Bar | 5456 H111 octagonal bars are used as polygonal brackets or specialized components in marine equipment, particularly for installations on offshore platforms or underwater facilities. Their shape is conducive to the fitting and stability of special structures, meeting the needs of complex marine engineering projects. |

| 5456 H111 Aluminum Round Bar | 5456 H111 round bars are commonly used for pipeline supports, fasteners, and other structural components on offshore platforms. Its excellent machinability and good resistance to seawater corrosion make it an indispensable material for ships and offshore platforms. |

| 5456 H111 Aluminum Square Bar | 5456 H111 square bars are widely used in frame structures and support components in the marine industry. They can be used for hull reinforcement, support beams on offshore platforms, and various corrosion-resistant marine engineering projects. |

Haomei 5456 H111 Aluminum Structurals (Extruded)

| Product Form | Description |

| 5456 H111 Shapes (Extruded) | 5456 H111 extruded shapes are widely used in structural components for ships and offshore platforms. Due to its lower strength and excellent formability, it is ideal for manufacturing complex structural shapes such as frames, beams, and support structures, capable of withstanding high corrosion pressures in marine environments. |

Haomei 5456 H111 Aluminum Structurals

| Product Form | Description |

| 5456 H111 Angle Aluminum | 5456 H111 angle bars are commonly used in the frame and support structures of ships and offshore platforms. Due to their excellent corrosion resistance and adequate strength, they are suitable for horizontal beams and vertical supports, ensuring the stability of structures in harsh marine environments. |

| 5456 H111 Angle (Unequal Leg) Aluminum | 5456 H111 unequal leg angle bars are widely used in marine engineering, especially in complex structures requiring different size supports, such as the frame systems of ships and offshore platforms. They provide strong structural stability and can effectively withstand mechanical loads in offshore environments. |

| 5456 H111 Beams (H) Aluminum | 5456 H111 H-beams are commonly used in the structures of offshore platforms and ships, especially in areas where large pressure and weight need to be supported. Their excellent corrosion resistance and high strength make them suitable for long-term use in marine environments. |

| 5456 H111 Beams (I) Aluminum | 5456 H111 I-beams are commonly used in support structures for offshore platforms, ships, and other marine facilities. This structural form effectively distributes loads and is suitable for use in harsh marine environments, with corrosion resistance and moderate strength. |

| 5456 H111 Channel Aluminum | 5456 H111 channel bars are used as support structures and framing materials in ships and offshore platforms. Due to their excellent weldability and strong corrosion resistance, they perform excellently in long-term exposure to seawater. |

| 5456 H111 Tees Aluminum | 5456 H111 T-bars are commonly used as crossbeams and support structures in marine and shipbuilding industries. Due to their excellent resistance to seawater corrosion, T-bars have a long service life in marine environments and are suitable for carrying important structural loads. |

| 5456 H111 Zees Aluminum | 5456 H111 Z-bars are typically used in reinforced frameworks and support structures for ships and offshore platforms. Their shape and corrosion resistance make them particularly suitable for load-bearing and reinforcement applications in marine environments. |

Haomei 5456 H111 Aluminum Tubular Products

| Product Form | Description |

| 5456 H111 Aluminum Pipe (Seamless) | 5456 H111 seamless pipes are commonly used in marine engineering as pipelines and conveyance systems, particularly for transporting seawater or other liquids in ships and offshore platforms. Its corrosion resistance makes it highly durable in seawater environments. |

| 5456 H111 Aluminum Tube (Rectangular) | 5456 H111 rectangular tubes are typically used in the frame structures and support systems of ships and offshore platforms. Its excellent corrosion resistance and formability make it widely used in marine structures, especially in areas that require high corrosion resistance. |

| 5456 H111 Aluminum Tube (Square) | 5456 H111 square tubes are used in marine applications such as shipbuilding, platforms, and underwater equipment frames. They not only provide high-strength support but also effectively resist seawater corrosion, making them ideal for long-term exposure in marine environments. |

Marine aluminum products you may be interested in

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5059 Marine Grade Aluminum Plate Sheet

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5383 Marine Grade Aluminum Plate Sheet

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5456 5454 5754 Marine Grade Aluminum Bar

5456 5454 5754 Marine Grade Aluminum Bar has certification from CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and its quality fully complies with world marine grade standards.

-

Marine Grade Aluminum Round Bar 5754 5454 5456

The quality of 5754, 5456, and 5454 marine-grade aluminum round bars fully meets the ship classification standards worldwide: CCS, DNV, NK, ABS, BV, LR, KR.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

Comparison with Other 5456 Aluminum Alloy States

5456 aluminum alloy is a high-strength alloy commonly used in marine and shipbuilding industries, offering excellent corrosion resistance, particularly in seawater environments. It exhibits different mechanical properties and applications depending on the heat treatment state.

5456 aluminum alloy has different performance characteristics and applications in various heat treatment states. States like H111, H112, and H116 are suitable for ships, marine engineering, and corrosion-resistant structural components, while states like H32, H321, and O are better for applications requiring further processing or higher strength.

- H111 State: Suitable for applications that do not require exceptionally high strength, such as ship hulls, marine platform structures, etc. It offers good formability and weldability, and strong corrosion resistance, but has lower strength.

- H112 State: Has slightly higher strength, making it suitable for applications that require a certain level of strength.

- H116 State: A high-strength state with excellent corrosion resistance, commonly used for structural components that require high resistance to corrosion, such as highly corrosion-resistant hull parts and marine platforms.

Advantages of 5456 H111 Aluminum

- Corrosion Resistance: Excellent corrosion resistance in seawater environments, making it an ideal choice for marine engineering and shipbuilding structures.

- Good Weldability: In the H111 state, 5456 aluminum alloy has excellent weldability, allowing for welding in complex structures, suitable for the needs of environments like offshore platforms.

- Formability: It has good ductility and formability, making it suitable for applications that require complex shapes and processing.

5456-H111 aluminum alloy is a material highly suited for marine, shipbuilding, and underwater environments. Its excellent corrosion resistance, moderate strength, and superior weldability make it widely used in these fields. Although its strength is lower than that of other heat-treated states of 5456 aluminum alloy, it still meets the needs of most marine structural components, especially in applications where high strength is not particularly required.