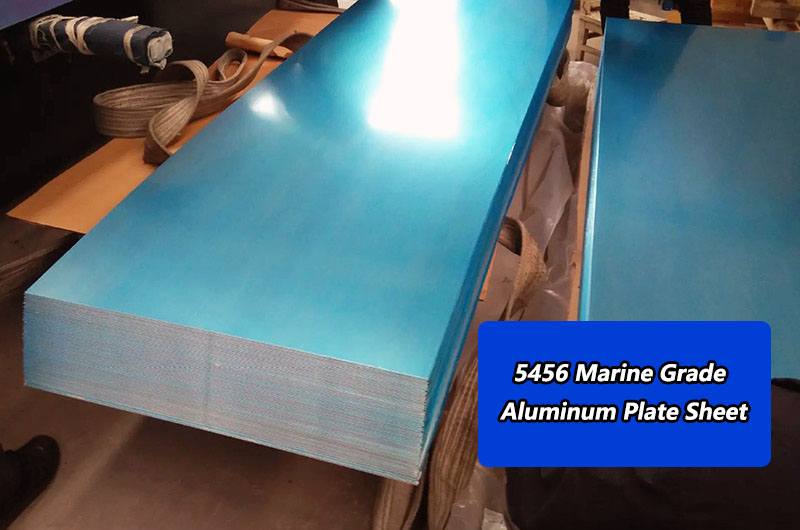

5456 Marine Grade Aluminum Plate Sheet

5456 aluminum plate is a forged aluminum-magnesium alloy, belonging to the 5000 series. It is known for its excellent corrosion resistance (especially in marine environments) and higher strength compared to similar products such as 5083.

5456 aluminum plate has enhanced mechanical strength, but it is more sensitive to stress corrosion, especially if improperly treated or exposed to high temperatures for prolonged periods.

Why choose 5456 for marine grade aluminum plate?

5456 aluminum is ideal for marine and aerospace applications that require a balance of strength, corrosion resistance, and weldability. Haomei Aluminum supplier offers customized sizes (thickness: 3-50 mm, width: ≤3600 mm), and has obtained global project certifications.

- Corrosion resistance: Marine environments are notorious for their corrosive nature, and salt water is particularly harsh. 5456 aluminum plate/sheet has excellent corrosion resistance under these conditions, making it ideal for marine structures, ships and offshore platforms. This resistance is mainly due to the alloying elements used in its composition.

- Strength: 5456 aluminum alloy has good strength properties, allowing it to withstand harsh marine environments. While not as strong as other aluminum alloys such as 5083, it is strong enough for many marine applications. The strength of the material makes it suitable for use in structural components such as hulls, masts and superstructures.

- Weldability: Weldability is a critical factor in marine applications as structures often require complex fabrication and repair. 5456 Aluminum has good weldability, enabling strong and durable welded joints to be formed without compromising its corrosion resistance. Optimum results require proper welding techniques and filler materials that are compatible with 5456 alloy.

- Formability: Marine grade aluminum should be easily formable to accommodate various manufacturing processes and design requirements. This property of 5456 aluminum alloy is crucial for the production of components with complex geometries, such as boat hulls and marine fittings.

Haomei Aluminum 5456 aluminum plate complies with ASTM B928 (marine service), ASTM B209 (sheet/plate), and EN 573-3.

Certified by marine classification societies: DNV, ABS, LR, CCS.

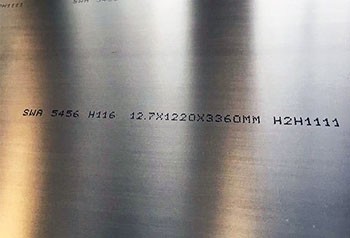

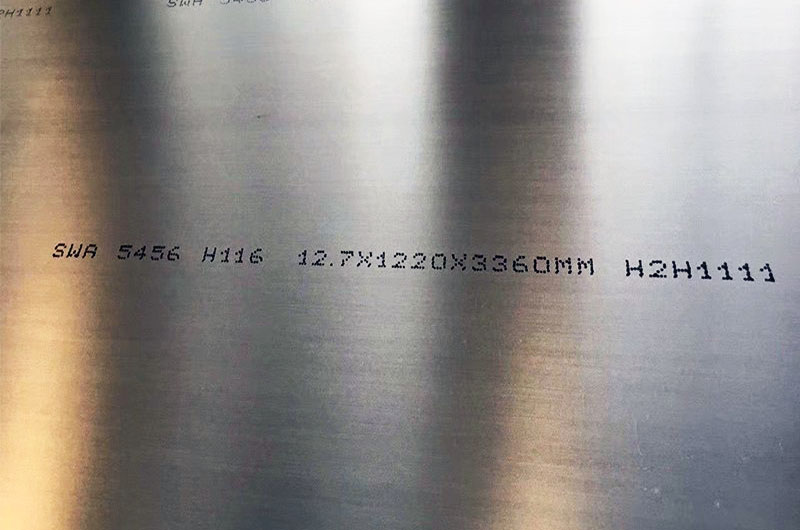

5456 Marine Grade Aluminum Plate Sheet Specifications

| Alloy | 5456 LF10 A5456 ALMg5Mn1 AMr5/1550 EN AW-5456A |

| Temper | O/H111/H112/H116/H321 |

| Thickness(mm) | 3-50 |

| Width(mm) | ≦3600 |

| Shape | Plate, sheet, panel |

| Feature | High Strength Welded Structure |

| Certification | CCS, DNV, NK, CCS, ABS, BV, LR, KR |

Marine aluminum products you may be interested in

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5059 Marine Grade Aluminum Plate Sheet

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5383 Marine Grade Aluminum Plate Sheet

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5456 5454 5754 Marine Grade Aluminum Bar

5456 5454 5754 Marine Grade Aluminum Bar has certification from CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and its quality fully complies with world marine grade standards.

-

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

Marine Grade Aluminum Round Bar 5754 5454 5456

The quality of 5754, 5456, and 5454 marine-grade aluminum round bars fully meets the ship classification standards worldwide: CCS, DNV, NK, ABS, BV, LR, KR.

5456 Aluminum Plate Characteristics

| Feature | Description |

| Marine-grade corrosion resistance | 5456 aluminum alloy exhibits excellent marine-grade corrosion resistance due to its magnesium content (4.7–5.5%) and chromium additions, especially in seawater and humid environments. It enhances resistance to pitting and exfoliation corrosion. |

| Mechanical strength | 5456 aluminum alloy has higher strength than 5083 and 5086 alloys, with ultimate tensile strength (UTS) ranging from 285–405 MPa, depending on the tempering process. It maintains high strength at sub-zero temperatures, making it suitable for low-temperature applications. |

| Weldability and formability | 5456 aluminum alloy is compatible with TIG, MIG, and spot welding techniques, ensuring strong joints in shipbuilding and aerospace structures. The alloy is available in states such as O (annealed), H111, H112, and H116, balancing ductility and work-hardened strength. |

| Lightweight advantage | With a density of 2.66–2.7 g/cm³, 5456 aluminum alloy can reduce ship weight by up to 20%, improving fuel efficiency and payload capacity. |

5456 Marine Grade Aluminum Plate Sheet Chemical Composition

| Alloy | 5456 | |

| Si | ≦0.25 | |

| Fe | ≦0.4 | |

| Cu | ≦0.1 | |

| Mn | 0.50-1.0 | |

| Mg | 4.70-5.50 | |

| Cr | 0.05-0.20 | |

| Zn | ≦0.25 | |

| Ti | ≦0.2 | |

| Zr | - | |

| Standard | EN573 | ASTM B928 |

5456 marine aluminum alloy Mechnical Properties

| Alloy | 5456 | |

| Tensile Strength | σbMpa) | ≥420 |

| Yield Strengthσ | 0.2Mpa) | ≥275 |

| Enlogation | (δ5%) | ≥10 |

5456 marine aluminum sheet specification

| TypIcial Alloy | 5456 | |

| Typcial Tempe | F, H112, F | |

| Thickness | (MM) | 3, 0~260 |

| Width | (MM) | 600~2600 |

| Length | (MM) | 1000-24000 |

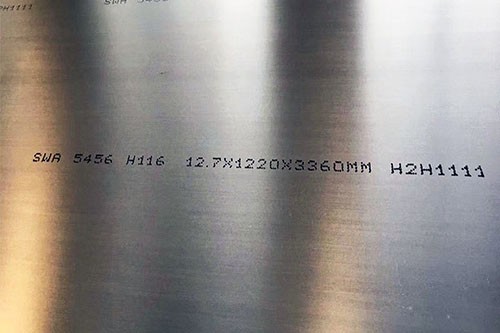

5456-h116 aluminum specification

| TypIcial Alloy | 5456 | |

| Typcial Tempe | H111 H116 | |

| Thickness | (MM) | 3.0~260 |

| Width | (MM) | 1000~4000 |

| Length | (MM) | 1000-38000 |

Comparison of 5456 Aluminum Plate with Other Alloys

| Comparison with other alloys | Description |

| Compared to 5083-H116 | 5456 aluminum alloy has higher strength than 5083-H116 alloy, but similar corrosion resistance in marine environments. While both exhibit excellent corrosion resistance, especially in seawater and humid conditions, the strength advantage of 5456 makes it more attractive for applications requiring higher load-bearing capacity, making it suitable for shipbuilding and other structural applications. |

| Compared to 6061-T6 | 5456 aluminum alloy has superior corrosion resistance in marine environments compared to 6061-T6 alloy. Especially in seawater and humid conditions, 5456 demonstrates stronger resistance to corrosion, while 6061-T6, with its lower magnesium content, is less resistant. However, 5456 has lower machinability, and 6061-T6 performs better in processing, welding, and forming, making it more suitable for some mechanical and structural applications. |

| Compared to 7075-T6 | 5456 aluminum alloy has lower strength than 7075-T6 alloy but performs better in weldability and corrosion resistance. 7075-T6 is known for its high strength and is commonly used in aerospace, but it has poor weldability and corrosion resistance, especially in marine environments. In contrast, 5456 aluminum alloy, with its excellent corrosion resistance and better weldability, is suitable for applications requiring high durability and strong joints, such as ships and marine structures. |

5456 Specification for Heat Treatment of Marine Aluminum Alloys

5456 Marine Grade Aluminum Plate Sheet is an aluminum-magnesium rust-proof aluminum plate with a strength equivalent to 5A03. Generally used for structural applications, it can be cold worked to produce higher strength. When stored for a long time at temperatures above 65°C, it is prone to spalling and corrosion.

- Homogenization annealing: heating to 480~495℃; holding for 12~14h; furnace cooling.

- Complete annealing: heating to 390~430℃, holding time 30~120min, furnace cooling to 300℃, and air cooling.

- Rapid annealing: heating 350~370℃; holding time 30~120min; air cooling.

- Quenching and aging: Quenching at 495~505℃, water cooling, artificial aging at 185~195℃, 6~12h, air cooling, natural aging: 96h at room temperature.

5456 Marine Grade Aluminum Plate Sheet product details

5456 Marine Grade Aluminum Plate Sheet Applications

Due to its characteristics, 5456 aluminum plate is used in:

- Marine applications: Widely used in the shipbuilding industry for decks, hulls, bulkheads, and other structural components, where corrosion resistance and durability are crucial.

- Aerospace and industrial uses: Its high strength-to-weight ratio also makes it highly suitable for aerospace components, structural parts in transportation, and certain construction applications.

| Application Field | Description |

| Shipbuilding | 5456 aluminum plate is widely used in the hull, deck, bulkhead, and armor plates of patrol boats, yachts, and naval vessels due to its excellent wave impact resistance and seawater corrosion resistance. Its high strength and good corrosion resistance allow these ships to serve for long periods in harsh marine environments, providing better structural stability and protection performance. |

| Aerospace | 5456 aluminum plate is favored in the aerospace field for its high strength-to-weight ratio. It is used in critical components such as aircraft fuel tanks, spacecraft frames, and instrument supports. Its high strength and low weight enable it to provide exceptional structural support in demanding aerospace applications while reducing fuel consumption and improving range. |

| Marine Engineering | 5456 aluminum plate plays a vital role in marine engineering, especially in offshore platforms, wind turbine support structures, and deep-sea mining equipment. Its corrosion resistance and strength enable it to withstand challenges in the marine environment, such as salt mist, wave impact, and high-pressure conditions, ensuring long-term stable operation and fatigue resistance of the equipment. |

| Military | 5456 aluminum plate is commonly used in the military sector due to its lightweight and high-strength characteristics, particularly in naval vessels and amphibious vehicles for lightweight armor. It provides sufficient protection while maintaining a low weight, enhancing mobility and combat effectiveness. In applications requiring impact resistance and high durability, 5456 aluminum plate performs excellently, able to withstand harsh combat environments. |

5456 Aluminum Plate Advantages and Considerations

5456 Aluminum Plate Advantages

- Corrosion Resistance: Performs excellently in saltwater and humid environments, making it more popular in marine applications.

- Strength: Higher strength compared to similar alloys (e.g., 5083), suitable for load-bearing applications.

- Weldability and Formability: Good weldability, easy to manufacture, thereby reducing the overall weight of structures like ships.

5456 Aluminum Plate Limitations

Stress Corrosion Sensitivity: Despite its high strength, the alloy may be more susceptible to stress corrosion when exposed to certain conditions (e.g., prolonged exposure to temperatures above 65°C).

Considerations

- Cannot be heat treated; strength is achieved through cold working.

- Avoid prolonged exposure to temperatures above 65°C to prevent corrosion degradation.

5456 aluminum plate is a strong, corrosion-resistant material that is ideal for marine and structural applications. Its composition (primarily aluminum, with a high magnesium content) results in a material that is both strong and weldable, but attention must be given to stress corrosion and temperature exposure. It meets international standards, making it a reliable choice for high-performance applications in the maritime and aerospace industries.

Precautions for purchasing 5456 marine grade aluminum plate

- Grade certification: Verify whether the aluminum plate meets the 5456 marine grade standard. This ensures that the material has the properties needed to withstand the marine environment.

- Thickness: Determine the aluminum plate thickness required for the application.

- Alloy composition: Understand the alloy composition of 5456 aluminum, which usually contains magnesium as the main alloying element. This composition provides excellent corrosion resistance and strength, which are critical for marine applications.

- Corrosion Resistance: Confirm that aluminum plate has excellent corrosion resistance as this is one of the main reasons to choose marine grade aluminum. The panels should be resistant to salt water corrosion common in marine environments.

- Surface finish: Consider the surface finish of the aluminum plate. Depending on the requirements, boards may be required with a specific surface finish, such as ground or polished, for aesthetic or functional purposes.

- Cost and Budget: Consider the cost of aluminum panels and make sure it fits your budget. While quality is crucial, it is also important to find a balance between quality and cost-effectiveness.

Tags: Marine Aluminum 5456