Aluminium 5083 H111

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

Its chemical composition (4.0-4.9% magnesium, 0.4-1.0% manganese, up to 0.25% chromium, and the remainder aluminum) gives it strength and ductility.

In the H111 temper, 5083 undergoes slight work hardening (lower than H11), achieving a balance between formability and mechanical properties during the forming process.

5083-H111 aluminum alloy is a non-heat-treatable alloy in the 5xxx series, renowned for its excellent strength, corrosion resistance, and suitability for applications in marine and industrial sectors.

Aluminium 5083 H111 Chemical Composition

The alloy primarily consists of magnesium (4.0-4.9%) and manganese (0.4-1.0%), with trace elements such as chromium and titanium. This composition enhances its resistance to seawater and chemical corrosion, while maintaining weldability.

- Magnesium (Mg): 4.0–4.9% (by weight), the primary strengthening element

- Manganese (Mn): 0.4–1.0%, improves strength and corrosion resistance

- Chromium (Cr): 0.05–0.25%, controls grain structure and improves toughness

- Other elements: Silicon ≤ 0.4%, Iron ≤ 0.4%, Copper ≤ 0.1%, Titanium ≤ 0.15%, Zinc ≤ 0.25%

| Element | % Present |

| Magnesium (Mg) | 4.00–4.90 |

| Manganese (Mn) | 0.40–1.00 |

| Chromium (Cr) | 0.05–0.25 |

| Iron (Fe) | ≤0.40 |

| Silicon (Si) | ≤0.40 |

| Aluminium (Al) | Balance |

Aluminium 5083 H111 Tempering and Mechanical Properties

H111 temper definition

H111 temper refers to "work hardening imparted by the forming process, but with a hardness lower than that required for H11 temper", and it is achieved without additional heat treatment.

This temper is typically applied to rolled and flattened plate and sheet materials, offering medium strength and good formability.

Aluminium 5083 Mechanical Properties (H111)

- Yield Strength (0.2% offset): ~228 MPa

- Ultimate Tensile Strength: ~317 MPa

- Elongation at Fracture: 16% (typical value)

- Brinell Hardness: ~85 HB

Aluminium 5083 H111 Physical and Thermal Properties

- Density: 2.66 g/cm³ (common value for 5xxx alloys)

- Elastic Modulus: ~72 GPa

- Thermal Conductivity: ~121 W/m·K

- Resistivity: ~0.058 × 10⁻⁶ Ω·m

- Maximum Service Temperature: ≤ 65 °C, to avoid strength loss

Haomei Aluminium 5083 H111 Supply Forms and Specifications

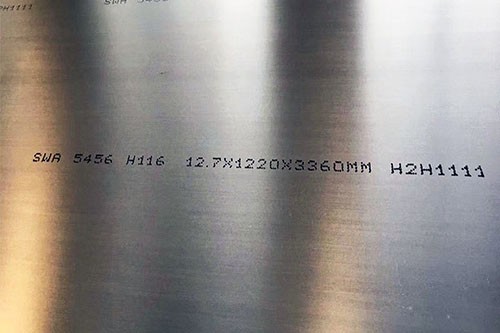

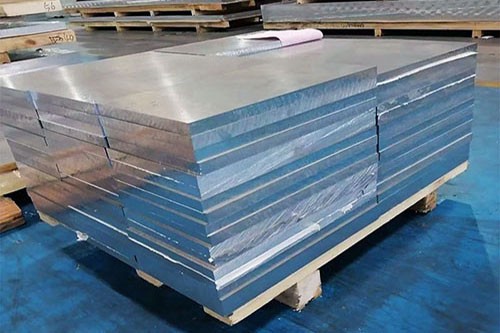

Aluminium 5083 H111 is typically produced according to ASTM B209/ASME SB209 and EN AW-5083 standards and is available in various forms - primarily as sheets, plates, coils/strips, and custom shapes - with thicknesses ranging from thin foils to thick structural plates.

| Supply Form | Description | Dimensions |

| Aluminium 5083 H111 Sheet | Flat-rolled product, formable and plyable. | Thickness: 0.2–6.3 mm Width: 500–2500 mm Length: Custom |

| Aluminium 5083 H111 Plate | Thicker flat product for structural and marine uses. | Thickness: 6–300 mm Width: 1000–6000 mm Length: 1000–10000 mm |

| Aluminium 5083 H111 Coil & Strip | Cold-rolled coils or slit strips for continuous fabrication. | Thickness: from 0.2 mm Width: 500–2500 mm |

| Aluminium 5083 H111 Blanks, Circles, Rings | Pre-cut round or shaped flat products for flanges and pressure vessels. | Custom sizes |

| Aluminium 5083 H111 Checkered/Diamond Plate | Textured surface for anti-slip flooring, marine decks. | Same as plate; pattern adds slight extra thickness |

| Aluminium 5083 H111 Foils | Ultra-thin sheets for cryogenic, chemical or packaging applications. | Thickness: down to 0.05 mm |

Aluminium 5083 H111 Surface Finishes and Coatings

| Category | Type | Description / Purpose |

| Mill Finish | Standard as-rolled surface | Basic finish directly from rolling mill; no additional treatment. |

| Decorative | Bright, Polished, Hair-line, Brush, Sand-blast | Aesthetic surfaces for visual appeal in architecture or design. |

| Functional | Checkered (Tread), Embossed, Etched | Textured or patterned for anti-slip or structural function. |

| Coatings | PVC, Polyester, Fluorocarbon, Polyurethane, Epoxy | Surface protection for UV resistance, chemical durability, and longevity. |

Aluminium 5083 H111 Manufacturing and Weldability

5083-H111 is easily welded using gas and arc welding processes, with the weld zone maintaining excellent strength without cracking.

Weldability is generally poor, with the mechanical processing being the reason for moderate strain hardening.

Welding:

- Recommended methods: Arc welding and resistance welding (preferred).

- Filler metals: 5183, 5356, or 5556, for self-welding or similar alloy welding.

Challenges: Poor brazing and weldability.

- Machinability: Rated poor due to poor ductility; requires specialized tools for CNC processing.

- Cold working: Moderate, suitable for bending in O/H111 temper.

Aluminium 5083 H111 Corrosion Resistance

Due to its high magnesium content forming a stable oxide film, this alloy exhibits excellent resistance to seawater, industrial chemicals, and atmospheric environments.

At low temperatures (-195°C), the ultimate tensile strength increases by about 40%, yield strength increases by about 10%, and it maintains excellent fracture toughness.

Aluminium 5083 H111 Applications

Its common applications fully leverage its corrosion resistance, weldability, and strength:

- Marine structures: Hulls, decks, and superstructures of ships and offshore platforms

- Pressure vessels and tanks: Cryogenic vessels and fuel storage

- Transportation: Rail vehicles, truck bodies, and automobile fuel tanks

- Defense and cryogenics: Vehicle armor, liquefied natural gas tanks, and cryogenic applications

- Cryogenics: Maintains strength at temperatures as low as -195°C.

| Application Area | Description |

| Shipbuilding | Aluminium 5083 H111 performs excellently in the shipbuilding industry, widely used in hull structures, decks, and superstructures. Its high strength and excellent corrosion resistance allow it to effectively resist seawater and marine environment corrosion, extending the service life of the hull. Additionally, its lower density enables lightweight design, reducing ship weight by 15%–20% compared to traditional steel, thus improving fuel efficiency and cruising speed, making it suitable for various types of vessels such as speedboats, patrol ships, fishing boats, and yachts. |

| Transportation - Automotive | Aluminium 5083 H111 is widely used in automobile manufacturing, particularly in load-bearing parts such as body frames, engine blocks, and chassis structures. Its lightweight property significantly reduces the vehicle weight, improving handling while effectively reducing fuel consumption and carbon emissions. Additionally, its good weldability and machinability make it suitable for mass production of complex body structures, meeting the dual requirements of performance and environmental protection in modern automotive industries. |

| Transportation - Rail Vehicles | Aluminium 5083 H111 also holds an irreplaceable position in rail transportation, commonly used in car body skins, floors, chassis, and structural frames. Its excellent strength-to-weight ratio helps significantly reduce the weight of the train, thereby improving operational energy efficiency, reducing wear, while enhancing the train’s impact resistance and structural safety. Its corrosion resistance also ensures long-term stability in various climatic environments, making it particularly suitable for the manufacture of subways, high-speed trains, and light rail vehicles. |

| Industrial Equipment | Aluminium 5083 H111 is also widely used in various industrial equipment, especially in the manufacturing of tankers, pressure vessels, and various welded structural parts. Its outstanding welding performance ensures the strength and sealing of joints, while its high strength properties allow it to withstand mechanical loads in high-pressure environments, ensuring the equipment remains stable and safe during transportation and storage. Furthermore, its corrosion resistance makes it more reliable and durable in industries such as chemicals, food processing, and energy. |

Aluminium 5083 H111 Comparison with Other Tempers

- H112: Similar composition but heat-treated to improve stability.

- H321: Higher strength due to heat treatment but poorer formability.

Aluminium 5083 H111 Standards and Specifications

- EN AW-5083 (AlMg4.5Mn0.7) complies with EN 573-3

- ASTM B928 / AMS-QQ-A-200 applies to plates and thin sheets

- Alloy codes: GM41, A95083, AIMg 4.5 Mn, Al Mg 4.5 Mn 0.7

5083-H111 aluminium is highly suitable for applications requiring high strength-to-weight ratio, corrosion resistance, and weldability. Its limitations in machinability and high-temperature performance are offset by its versatility in harsh environments.

Marine aluminum products you may be interested in

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5059 Marine Grade Aluminum Plate Sheet

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5383 Marine Grade Aluminum Plate Sheet

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

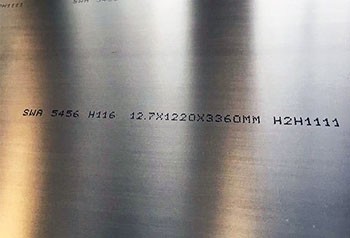

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.