Aluminum 5083 H112

5083-H112 aluminum alloy is a non-heat-treatable alloy primarily composed of aluminum, magnesium, and trace amounts of manganese and chromium. It is renowned for its excellent corrosion resistance, especially in marine and industrial environments, and retains high strength even after welding.

5083-H112 aluminum alloy is a non-heat-treatable Al-Mg-Mn alloy that has been optimized for lightweight, high strength, and corrosion resistance. In the H112 temper condition, it undergoes strain hardening through controlled thermal processing.

5083 H112 aluminum alloy is mainly used in shipbuilding, structural, and transportation applications. The H112 temper designation indicates that the alloy undergoes slight strain hardening during manufacturing, usually due to hot or cold working, but it does not reach specific mechanical property limits.

5083 H112 maintains excellent weldability with minimal loss of performance. Its density is 2.66 g/cm³, and its thermal conductivity is approximately 117 W/m·K, making it suitable for marine, cryogenic (as low as –195 °C), and automotive applications.

Aluminum 5083 H112 Chemical Composition

5083-H112 complies with UNS A95083 / ISO AlMg4.5Mn standards:

- Aluminum: Balance (92.4–95.6 wt%)

- Magnesium: 4.0–4.9 wt%

- Manganese: 0.4–1.0 wt%

- Chromium: 0.05–0.25 wt%

- Silicon: ≤ 0.4 wt%

- Iron: ≤ 0.4 wt%

- Titanium: ≤ 0.15 wt%

- Zinc: ≤ 0.25 wt%

- Copper: ≤ 0.10 wt%

- Others (each): ≤ 0.05 wt%; Total content ≤ 0.15 wt%

Aluminum 5083 H112 Physical Properties

- Density: 2.66 g/cm³ (0.0961 lb/in³)

- Thermal Conductivity: 117 W/m·K (typical)

- Coefficient of Thermal Expansion: 23.8 µm/m-°C (20–100 °C)

- Specific Heat Capacity: 0.9 J/g-°C

- Melting Range: 591–638 °C

Aluminum 5083 H112 Mechanical Properties

- Ultimate Tensile Strength (UTS): 300 MPa (43.5 ksi)

- Yield Strength (0.2% offset): 190 MPa (27.6 ksi)

- Elongation at Break: ~16% in 50 mm (2") specimen

- Modulus of Elasticity: 70 GPa

- Brinell Hardness: 81 HB (calculated)

- Shear Strength: ~180 MPa

- Fatigue Strength: Approximately 110 MPa

Aluminum 5083 Temper Designation H112

- H1x Series: Strain-hardened only (not heat-treated to increase strength).

- H112: Applicable to products that have been strain hardened and then subjected to thermal treatment (e.g., controlled thermal stretching) to achieve specific mechanical properties and good ductility.

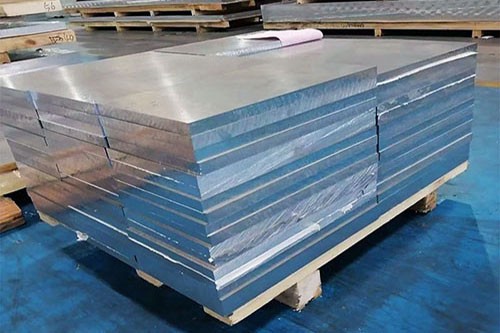

Haomei Aluminum 5083 H112 Supply Forms

| Form | Description |

| Aluminum 5083 H112 Plate | Heavy gauge, often used in shipbuilding, tanks, and pressure vessels. |

| Aluminum 5083 H112 Sheet | Thinner than plate, used for panels, enclosures, and lightweight structures. |

| Aluminum 5083 H112 Coil | For continuous processing, including roll forming or stamping applications. |

| Aluminum 5083 H112 Round Bar / Rod | For structural components, shafts, and marine fittings. |

| Aluminum 5083 H112 Flat Bar | For frameworks, walkways, and reinforcement. |

| Aluminum 5083 H112 Square and Rectangular Bar | Used in construction and architectural applications. |

| Aluminum 5083 H112 Pipe / Tube (Seamless and Welded) | Often used for fluid handling in marine and industrial systems. |

| Aluminum 5083 H112 Extrusions / Profiles | Custom profiles for marine decks, structural frames, or trailers. |

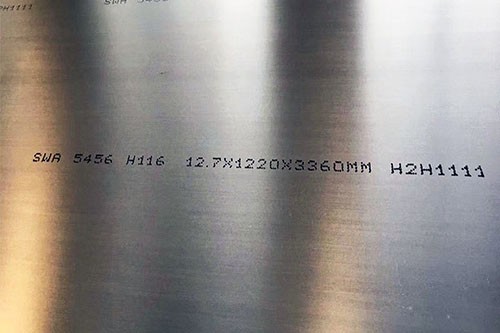

Haomei Aluminum 5083 H112 Typical Specifications and Dimensions

| Form | Typical Thickness / Size Range | Length Options |

| Aluminum 5083 H112 Sheet | 0.5 mm – 6 mm | Up to 4000 mm |

| Aluminum 5083 H112 Plate | 6 mm – 200 mm+ | 2000 mm × 4000 mm / custom sizes |

| Aluminum 5083 H112 Coil | 0.5 mm – 3 mm (width up to 1600 mm) | Coil weight 1–5 tons, custom length |

| Aluminum 5083 H112 Round Bar | Ø6 mm – Ø300 mm | 3000 mm / custom cut-to-length |

| Aluminum 5083 H112 Flat Bar | 10 mm × 20 mm to 50 mm × 150 mm | 3000 mm or customized |

| Aluminum 5083 H112 Pipe / Tube | OD: 10 mm – 300 mm; wall thickness as needed | 3000 mm or per project requirements |

| Aluminum 5083 H112 Extruded Profiles | Custom shapes per drawing or industry standard | Up to 6000 mm |

Core Characteristics of Aluminum 5083 H112

| Core Characteristic | Description |

| Corrosion Resistance | 5083 H112 exhibits excellent corrosion resistance, particularly in marine environments and humid atmospheres. Its high magnesium content (approximately 4.0-4.9%) gives it exceptional resistance to salt spray corrosion, making it widely used in ship structures, offshore platforms, port facilities, and seawater treatment systems. It can withstand saltwater exposure for long periods without rusting or performance degradation. |

| High Strength | 5083 H112 has relatively high strength among non-heat-treatable aluminum alloys, making it especially suitable for welded structures requiring high load-bearing capacity. It maintains good mechanical properties in welded zones, which is why it is commonly used for hull frameworks, deck structures, tanks, and high-pressure equipment. |

| Weldability | 5083 H112 offers excellent weldability and moderate machinability. The alloy supports various welding methods such as TIG, MIG, and resistance welding. The welding process is stable, with good forming quality and minimal risk of cracking at the weld seam. While not as easy to machine as cutting-specific alloys, conventional machining operations like turning, milling, and drilling can be performed under controlled parameters. |

| Low Temperature Performance | 5083 H112 retains excellent mechanical properties at low temperatures. Its yield strength and ductility do not decrease but may even improve under such conditions. Thus, it is especially suitable for equipment and structures operating in low or extreme cold environments, such as cryogenic storage tanks, polar transport containers, and refrigerated ship structures. |

| Compatibility with Welding Technologies | 5083 H112 offers excellent weldability, supporting not only traditional fusion welding methods but also more advanced joining technologies such as resistance spot welding and self-piercing riveting. This makes it highly versatile for lightweight structural manufacturing, especially for mixed-material joints with high reliability, minimal deformation, and strong weld seams. |

| Workability | 5083 H112 features good hot workability and moderate cold forming capability. In the annealed state, it is easy to perform bending, stamping, and other plastic forming operations, making it suitable for manufacturing large and complex structures. Although not as formable in cold conditions as pure aluminum or soft alloys, it can still handle general flanging, bending, and shallow drawing processes, ideal for medium-complexity components in mass production. |

Corrosion Resistance of Aluminum 5083 H112

5083-H112 exhibits excellent resistance to seawater and industrial chemicals due to its high magnesium content and formation of a protective oxide film. It resists pitting and crevice corrosion in marine environments and can be anodized for enhanced surface protection,

making it a primary alloy for hulls, decks, and superstructures.

Weldability of Aluminum 5083 H112

5083-H112 retains approximately 90% of its base metal strength after welding with MMA, MIG, or TIG methods. Due to its very low cracking tendency and excellent solid solution strengthening, this alloy offers superior toughness. Friction Stir Welding (FSW) can further refine its microstructure and reduce porosity, providing high-integrity welds for shipbuilding and pressure vessel fabrication.

Formability of Aluminum 5083 H112

This alloy possesses good cold forming properties (rolling, bending, stamping) and hot forming capabilities (bending at 300–450°C), with a low springback rate. Machinability is acceptable. Pre-drilling and using sharp tools are recommended to avoid work hardening during machining.

Standards and Specifications of Aluminum 5083 H112

- ASTM B209 / ASME SB209: Plate

- ASTM B928: Tubing

- EN 573-3 / EN 754-2: Chemical composition and mechanical properties

- ISO 6361: Wrought aluminum plates, strips, and sheets

- ASTM B221 – Standard for extruded bars, rods, wires, and profiles

- ASTM B210 / B241 – Seamless and welded tubes

- ASTM B209: Main standard for plate and sheet

- EN 485-2: European mechanical property specification

Typical Applications of Aluminum 5083 H112

- Marine and Shipbuilding: Hull plates, decks, bulkheads, offshore platforms

- Pressure Vessels and Storage Tanks: LNG carriers, chemical tanks

- Railway and Road Vehicles: Lightweight bodies, mining skips, railcars

- Cryogenic Equipment: LNG storage tanks and pipelines for temperatures down to -195°C

- Armor and Defense: Vehicle armor plates

- Structural Components: Bridges, building facades, architectural panels

- Offshore and Energy: Drilling platforms, wind turbine bases

| Application Fields | Description |

| Shipbuilding | 5083-H112 is widely used in shipbuilding, especially in hulls, decks, and propeller shafts, which are in direct contact with seawater. Its excellent seawater corrosion resistance and high strength allow it to effectively resist salt spray corrosion and mechanical fatigue during long-term sailing and marine operations, ensuring the stability and safety of the ship structure. Therefore, 5083-H112 has become the preferred aluminum alloy material for fast boats, warships, and ocean-going cargo ships. |

| Transportation | 5083-H112 is commonly used in the transportation industry for manufacturing automotive chassis, aircraft fuel tanks, as well as subway and light rail vehicle sheet metal shells. Its high specific strength, good weldability, and excellent corrosion resistance make it meet the lightweight design requirements while enhancing the structural stability and durability of the whole vehicle. Especially in transportation systems with long-term operation and strong vibrations, 5083-H112 significantly extends the structural life and reduces maintenance frequency. |

| Industrial Equipment | 5083-H112 is suitable for manufacturing pressure vessels, cryogenic refrigeration equipment, TV towers, and other industrial structural components requiring fire and corrosion resistance. In these applications, the material needs to withstand strength tests in high-pressure or low-temperature environments and cope with corrosion challenges from chemical media or extreme environments. 5083-H112 plays a vital role in the industrial sector by improving the safety and service life of equipment with its stable physical properties and good thermal conductivity. |

| Construction | 5083-H112 is widely used in the construction industry for drilling platform equipment, structural support components, and other load-bearing elements. Its superior strength and good processing adaptability make it suitable for manufacturing large-span brackets, wind-resistant structures, and modular components that require frequent assembly. It meets the dual demands of structural reliability and weather resistance in modern construction, especially suitable for outdoor projects or coastal facility construction in high-humidity, high-salt environments. |

5083-H112 aluminum alloy is a versatile material, ideal for shipbuilding, transportation, and cryogenic applications. It strikes a balance in strength, corrosion resistance, and weldability, making it the material of choice for harsh environments.

Aluminum 5083 H112 Manufacturing and Processing

- Weldability: Excellent weldability when using filler materials such as 5183 or 5356. Suitable for arc welding and resistance welding.

- Machinability: Due to work hardening, machinability is relatively poor and requires specialized tools.

- Formability: Medium cold workability; avoid high-strain bending in hardened states.

- Temperature Limitation: Avoid long-term use at temperatures above 65°C (149°F), but it performs well at low temperatures as low as -195°C.

Aluminum 5083 H112 vs. Other States

- H111: Lower work hardening degree than H112, with slightly lower yield strength.

- H116/H321: Higher strength but lower ductility. Better corrosion resistance, more suitable for marine underwater environments.

- O State: Annealed state with higher elongation but lower strength.

| Comparison of States | Description |

| H111 | 5083 H112 has a higher degree of work hardening compared to 5083 H111, giving it a slightly higher yield strength. While both are non-heat treated work-hardened states, 5083 H112 provides more stable mechanical properties after greater plastic processing, making it suitable for applications that require certain strength but still need good formability. On the other hand, 5083 H111, with a smaller amount of deformation, has slightly lower yield strength and is more suitable for structures requiring high formability but relatively lower strength. |

| H116 / H321 | 5083 H112 has better ductility and lower residual stress compared to 5083 H116 or H321, making it more suitable for structures that require further processing or forming. Although H116 and H321 have higher strength and superior corrosion resistance due to special processing, particularly for ship hulls and underwater structures exposed to long-term immersion in seawater, their ductility and weldability are slightly inferior to 5083 H112. Therefore, 5083 H112 has an advantage in structural flexibility and weldability. |

| O State (Annealed) | 5083 H112 is significantly stronger than 5083 O state. The O state, being fully annealed, has extremely high elongation and excellent formability, making it suitable for complex bending or deep drawing applications. However, its tensile strength and yield strength are much lower than H112. 5083 H112 provides higher structural strength while maintaining a certain level of ductility, making it suitable for medium-strength applications where load-bearing or deformation resistance is necessary. Therefore, the two states differ significantly in performance orientation, with 5083 H112 being more suitable for engineering environments that require a balance of medium strength, good formability, and weldability. |

5083-H112 combines high strength, high toughness, high weldability, and excellent corrosion resistance, making it the material of choice for high-demand structural and shipbuilding applications.

Marine aluminum products you may be interested in

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5059 Marine Grade Aluminum Plate Sheet

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5383 Marine Grade Aluminum Plate Sheet

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.