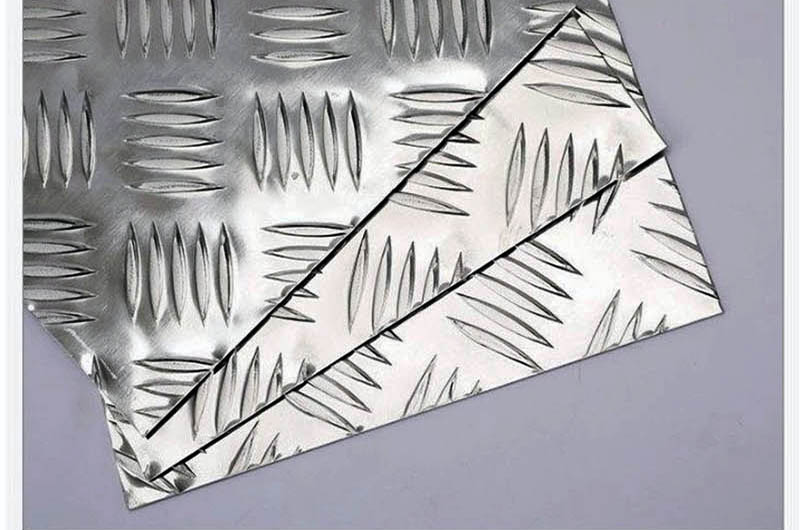

Marine grade aluminum checker plate

Marine grade aluminum checkered plates are commonly used on ship decks due to their excellent anti-slip properties and excellent corrosion resistance. The main varieties are 5052, 5086 and 5083.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

Marine grade aluminum checker plate has good anti-slip properties, is easy to clean and looks great. These products feature a decorative industrial look and you can rely on these products for decorative purposes. It is also known for its excellent resistance to seawater, which is why it is ideal for the marine industry.

Aluminum checker plate refers to its textured surface with a raised diamond or bar pattern. This design provides enhanced traction and reduces the risk of slipping, making it particularly suitable for use in marine applications where surfaces may be wet or slippery from water or other liquids.

Marine grade patterned aluminum plate refers to a specific type of aluminum plate designed and manufactured for use in marine environments. It is typically made from aluminum alloys with excellent corrosion resistance, such as 5000 series alloys such as 5052 or 5083.

Marine-grade aluminum checkered panels are commonly used on a variety of marine structures, including boat decks, gangways and platforms, and other applications where corrosion resistance and slip resistance are required. They are typically durable, lightweight, rust and corrosion resistant, making them ideal for harsh marine environments.

- Corrosion Resistance: Specifically designed to withstand the corrosive effects of saltwater and marine environments.

- Lightweight: Easier to handle and install compared to other materials like steel.

- Durability: Long-lasting and able to endure heavy use and exposure to harsh conditions.

- Non-slip Surface: The raised pattern provides excellent grip, enhancing safety.

- Low Maintenance: Resistant to rust and staining, requiring minimal upkeep.

Specifications of Marine Grade Aluminum Tread Plate

- Aluminum alloy grade: AA5083, 5086, 5052 (H116,H321)

- Pattern: 3 bars, 5 bars, diamond.

- Thickness: 0.8 – 12mm

- Width: 400-1220mm

- Length: max 6000mm

- Length and width tolerance: ± 10%.

- Thickness tolerance: ± 0.1 mm.

| Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) |

| 5052 |

F,O,H12,H14, H16,H18,H19, H22,H24,H26, H28,H32,H34, H36,H38,H111, H112,H114 |

3-50 | 20-2650 | 500-16000 |

| 5083 |

O,H12,H14, H16,H18,H19, H22,H24,H26, H28,H32,H34 H36,H38,H111, H112,H114,H 116,H321 |

3-50 | 20-2600 | 500-16000 |

| 5086 | O/H111/H112/H116/H321 | 3-50 | ≦3600 | 500-16000 |

Haomei Marine grade aluminum checker plate product display

Chemical Composition of Marine Aluminum Checker Plate

| Alloy | 5052 | 5083 | 5086 |

| Si | 0.25 | 0.4 | 0.4 |

| Fe | 0.4 | 0.4 | 0.5 |

| Cu | 0.1 | 0.1 | 0.1 |

| Mn | 0.1 | 0.40-1.0 | 0.20-0.7 |

| Mg | 2.2--2.8 | 4.0--1.0 | 3.5--4.5 |

| Cr | 0.15-0.35 | 0.05-0.25 | 0.05-0.25 |

| Ni | - | - | - |

| Zn | 0.1 | 0.25 | 0.25 |

| Ti | - | 0.15 | 0.15 |

| Ga | - | - | - |

| V | - | - | - |

| Each | 0.05 | 0.05 | 0.05 |

| Total | 0.15 | 0.15 | 0.15 |

| Alu | Remainder | Remainder | Remainder |

Marine grade aluminum checker plate pattern

During the production process, the pattern is applied to the board by forming rollers that press the pattern against the board with great force. Thanks to the diagonal fin structure, the board becomes slip-resistant, which is why it is also suitable for use outdoors and in wet areas. In addition to fin structures, there are many other shapes and patterns that offer the same properties and are suitable for wet areas such as ship decks, indoor and outdoor stairs, etc.

Depending on the type of board, 1 to 5 strips are arranged next to each other, forming a lattice pattern. It is divided into 1-bar (diamond), 2-bar, 3-bar and 5-bar patterns.

Marine grade aluminum checkerboard, rhombus and checkerboard are commonly used in marine environments due to their corrosion resistance and durability. Each of these boards features a different pattern that provides enhanced traction and aesthetics.

Marine grade aluminum diamond plate

Diamond plate is commonly used in marine applications for flooring, stair treads, and other areas where slip resistance is crucial. It is also resistant to corrosion and is easy to clean and maintain.

Diamond plate is commonly used in marine applications on floors, stair treads and other areas where slip resistance is critical. It is also corrosion-resistant and easy to clean and maintain.

5 bar marine grade aluminum tread plate

The 5 bar Marine grade aluminum tread plate pattern consists of five raised bars arranged in a parallel pattern on the surface of the aluminum plate. This pattern provides enhanced grip and stability, making it suitable for applications where slip resistance is critical.

Like other marine grade aluminum tread plates, the 5 bar Marine grade aluminum tread plate is corrosion resistant and can withstand exposure to salt water and harsh marine conditions. It is commonly used for floors, ramps and other marine structural applications.

2 bar marine grade aluminum tread plate

The 2 bar Marine grade aluminum tread plate pattern features two raised bars running parallel across the surface of the aluminum plate. While it may not provide as much traction as a 5-bar pattern, it can still provide better grip than a smooth surface.

This pattern is typically used in applications where moderate slip resistance is sufficient, such as boat decks, dock surfaces and marine walkways.

All in all, marine grade aluminum tread, diamond and tread boards are all designed to provide slip resistance and durability in marine environments. Each mode offers unique advantages based on the specific requirements of the application.

Surface treatment of marine grade aluminum checker plate

The surface treatment of marine aluminum checkered plate serves a variety of purposes, including corrosion resistance, durability and aesthetics.

Mill finish marine grade aluminum tread checker plate

Rolled finish refers to the surface condition of aluminum after it has been extruded or rolled without any additional surface treatment.

While it retains the natural look of aluminum, it may lack certain properties, such as enhanced corrosion resistance.

Typically used in applications where corrosion resistance is not a primary consideration, or where subsequent surface treatment is required.

Bright finish marine grade aluminum tread checker plate

Glossy finishes involve additional mechanical or chemical processes to achieve a smooth, shiny surface.

It enhances the appearance of aluminum, giving it a polished and reflective effect.

Due to the smoother surface, gloss finishes may offer slightly better corrosion resistance than milled finishes, but for marine environments, additional protective coatings may still be required.

Anodized marine grade aluminum tread checker plate

Anodizing is an electrochemical process that forms a protective layer of oxide on the surface of aluminum.

This layer improves corrosion resistance, abrasion resistance and also provides color options.

Anodized marine grade aluminum tread checker plate is commonly used in marine environments due to its excellent resistance to salt water corrosion and durability.

The anodizing process can produce a variety of finishes, including matte, satin, or gloss, depending on the desired aesthetic and functional requirements.

Each surface treatment option has its advantages and is selected based on the specific requirements of the application such as environmental conditions, durability and desired appearance. In marine environments where corrosion resistance is critical, Anodized marine grade aluminum tread checker plates are often preferred for their superior protection against salt water corrosion.

Marine grade aluminum checker plate specific applications

Deck Flooring

Marine grade aluminum checker plates are widely used as deck flooring on boats and ships. The raised pattern provides a non-slip surface, which is crucial for safety, especially in wet and slippery conditions. The aluminum's resistance to saltwater corrosion makes it ideal for prolonged exposure to marine environments.

Gangways and Ramps

Checker plates are often used for gangways and ramps, providing a sturdy and slip-resistant surface for boarding and disembarking. The lightweight nature of aluminum allows for easy handling and installation without compromising strength and durability.

Engine Room Flooring

In engine rooms, where oil and other fluids can create hazardous conditions, marine grade aluminum checker plate is used for flooring. Its non-slip properties help prevent accidents, and its resistance to corrosion ensures long-lasting performance despite the presence of chemicals and moisture.

Stair Treads and Ladders

Stairs and ladders on ships and offshore platforms frequently utilize aluminum checker plates. The textured surface provides additional grip, reducing the risk of slips and falls. Additionally, aluminum's lightweight nature makes it easier to install and maintain.

Helideck Platforms

Offshore oil rigs and large vessels often have helidecks for helicopter landings. Marine grade aluminum checker plate is used for these platforms due to its durability, corrosion resistance, and non-slip properties, which are essential for the safety of helicopter operations in maritime environments.

Cabin and Interior Flooring

Inside cabins and other interior spaces on boats and yachts, aluminum checker plate is used for flooring. It not only offers a stylish, modern look but also provides practical benefits like easy cleaning, non-slip surface, and resistance to moisture and mildew.

Storage and Cargo Areas

In storage and cargo areas, where heavy loads and frequent movement can cause wear and tear, aluminum checker plates are used to protect surfaces and provide a durable, non-slip base. This application is common in both commercial and recreational vessels.

Protective Barriers and Kick Plates

Aluminum checker plates are also used as protective barriers and kick plates on walls and doors to prevent damage from impacts and foot traffic. This is particularly useful in high-traffic areas on ferries, ships, and other marine vessels.

Precautions for purchasing marine grade aluminum tread checker plate

When purchasing marine grade aluminum grating, there are several factors you should consider to ensure you are getting the right product for your needs. Here are some key things to note:

- Alloy grade: Ensure that the aluminum plate is made from a marine grade alloy suitable for use in marine environments. Common marine grade alloys include 5083, 5086 and 5052, which are known for their excellent corrosion resistance and strength.

- Thickness: Determine the appropriate thickness of the aluminum plate based on the intended use and structural requirements. Thicker panels offer greater strength and durability but can be heavier and more expensive.

- Surface Finish: Consider the desired surface finish and treatment options, such as milled finish, gloss finish, or anodized finish. Choose a finish that provides the necessary corrosion resistance and meets aesthetic preferences.

- Lattice board patterns: Lattice boards come in various patterns and sizes. The choice of tread plate pattern depends on factors such as slip resistance, aesthetics and practicality for the intended use. If the panels will be used in areas prone to slipping, make sure the pattern meets safety standards.

- Size and Dimensions: Specify the required size, dimensions, and quantity of the aluminum checkered panels based on your project's specifications

- Certifications and standards: Verify that aluminum plates comply with relevant industry standards and certifications for marine applications. This ensures product quality, performance and compliance with safety and regulatory requirements.

- Cost and Budget: Consider the overall cost, including the price of the panels, shipping, taxes, and any additional services or customizations.

- Paying attention to these factors when purchasing marine grade aluminum checkerboard will ensure you choose the right product that meets your requirements for durability, corrosion resistance, safety, and aesthetics.

Content you may be interested in

-

Marine grade aluminum diamond plate

Marine grade aluminum diamond plate not only has good anti-skid effect and anti-rust ability, but also has the characteristics of lightweight, which can improve the safety and economy of ships.

-

5 bar Marine grade aluminum tread plate

A 5 bar Marine grade aluminum tread plate is an aluminum plate with a patterned surface, featuring five raised bars or lines across the plate,This pattern provides enhanced traction and slip resistance.

-

2 bar Marine grade aluminum tread plate

The surface of a 2 bar Marine grade aluminum tread plate is embossed with two raised bars or lines, forming a pattern that resembles a series of parallel ridges. 2 bar pattern provides enhanced grip and traction.