Marine grade aluminum honeycomb plate

Marine grade aluminum honeycomb panel is a lightweight composite material widely used in the marine industry due to its excellent strength-to-weight ratio and corrosion resistance.

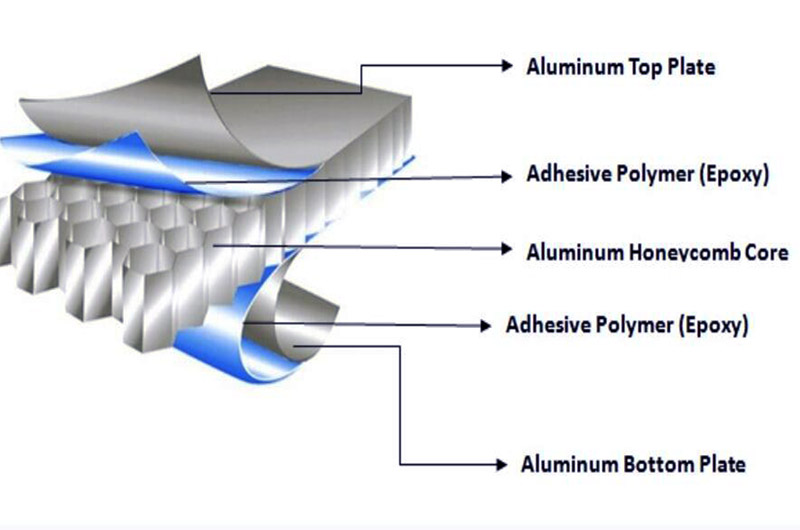

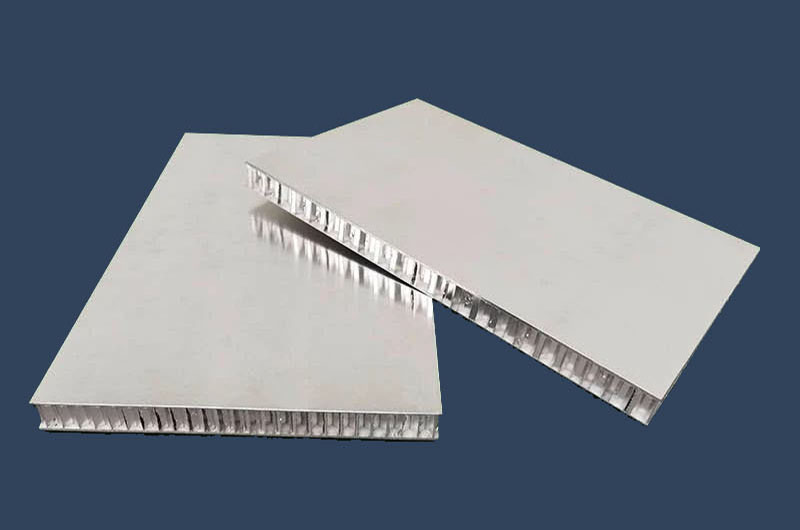

Marine grade aluminum honeycomb plate structure

Marine grade aluminum honeycomb panels are made of multi-layer aluminum plates bonded with a hexagonal honeycomb structure made of aluminum foil. This sandwich structure provides superior strength and rigidity while remaining lightweight.

The panels on both sides of the aluminum honeycomb panel are high-strength aluminum plates, and the inner layer is a special hexagonal aluminum honeycomb. As a core panel adhered to the sandwich structure, it bears pressure in the tangential direction. These dense honeycombs that restrain each other are like many small I-shaped honeycombs. The beam can disperse the pressure from the direction of the panel, so that the panel is evenly stressed, ensuring that the panel can still maintain a high flatness even in a large area.

Why choose honeycomb aluminum panels in the marine field?

- Lightweight: Reduce the overall weight of marine structures and improve fuel efficiency and maneuverability.

- Strength: Has a high strength-to-weight ratio, which is critical to maintaining structural integrity in harsh marine conditions.

- Corrosion Resistance: Resistant to salt water corrosion, a key factor in marine applications.

- Design Flexibility: Can be customized in a variety of shapes and sizes to meet specific design requirements.

- Thermal and Sound Insulation: Improve onboard comfort with thermal and sound insulation.

Main functions of marine grade aluminum honeycomb panels

- Structural Support: Provides structural integrity to the vessel, reducing weight while maintaining strength.

- Corrosion Resistance: Aluminum’s natural corrosion resistance combined with a protective coating ensures durability in harsh marine environments.

- Thermal Insulation: Provides thermal and acoustic insulation to increase comfort on board.

Marine grade aluminum honeycomb plate features

- Sound insulation and thermal insulation.

- Excellent strength to weight ratio

- Excellent fire rating (ASTM E84 A+ fire rating)

- Extremely resistant to moisture, rust and corrosion

- Improve performance

- Improve security

- Unparalleled longevity and life cycle

- Light weight and easy to process

- Easy to install

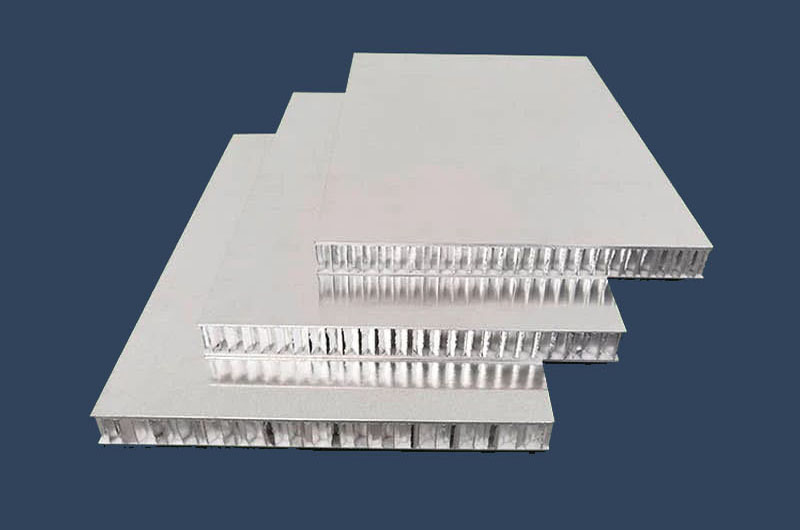

Marine grade aluminum honeycomb plate specifications

| Material | Aluminum Alloy (3003/5052, etc.) |

| Regular Size (W*L*T) | 1,220*2,440/3,000*6 mm |

| Max. Size(W*L*T) | 2,000*10,000*200 mm |

| Regular Thickness | 10/12/15/20/25 mm |

| Available Thickness | 6-200 mm |

| Regular Surface Treatment | PVDF,PE,Powder Coating, Anodized, etc. |

| Perforation | Yes (customized) |

| Applications | Wall cladding(exterior and interior), ceiling and flooring, cleanroom, partitions, ship hull, vehicles, tunnel, etc. |

| Customerization(MTM) | Yes (color, surface texture, size, shape, pattern, etc.) |

Suggestion:

- 1. For interior wall (PE coating): range from 8mm to 20mm (top plate:1.0mm; bottom plate: 0.7/0.8mm)

- 2. For exterior wall (PVDF coating): 15mm, 18mm, 25mm (top plate: from 1.0mm to 1.5mm; bottom plate: from 0.7mm to 1.0mm)

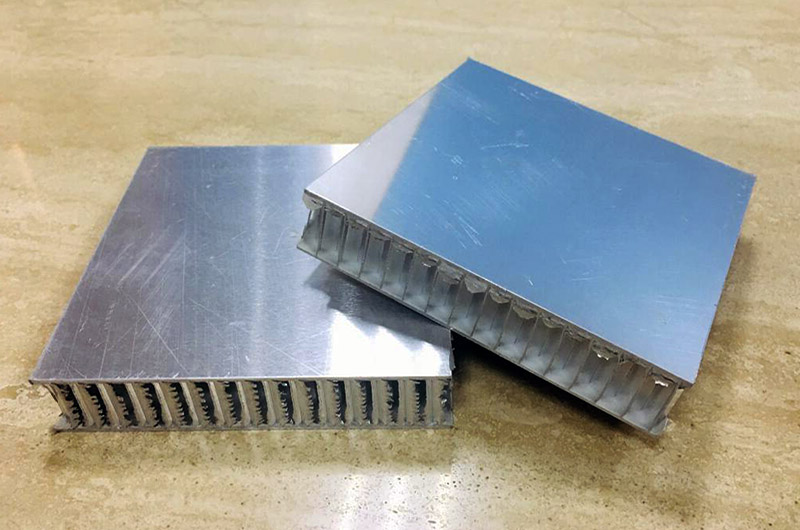

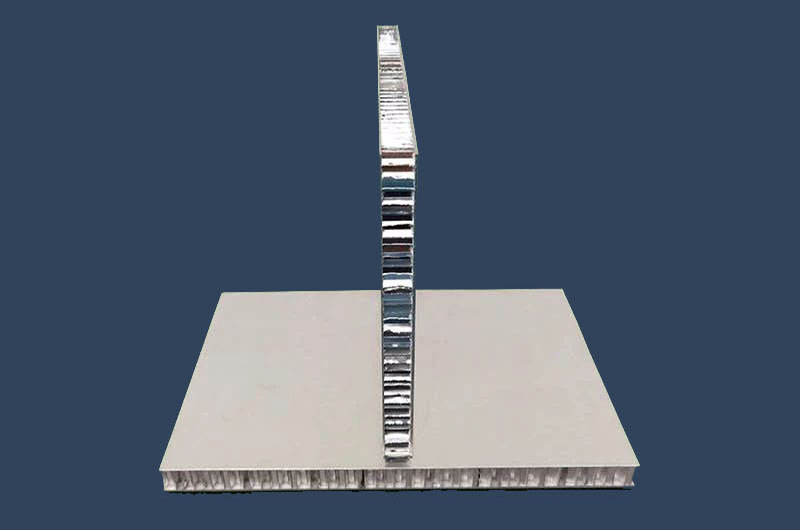

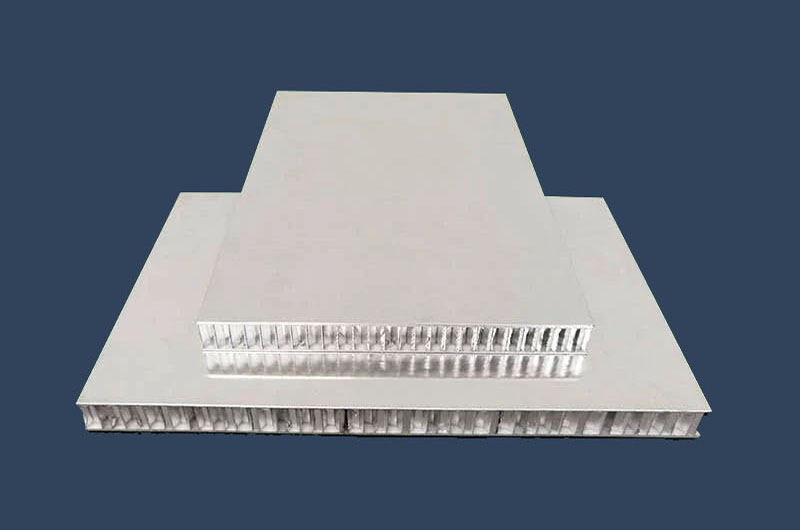

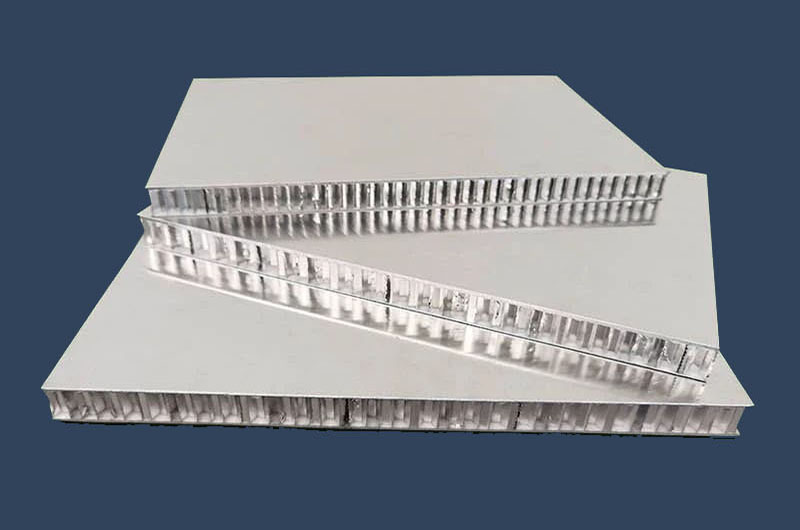

Marine grade aluminum honeycomb plate products real shot

Quality and appearance requirements for marine aluminum honeycomb panels

1. Surface requirements

The decorative surface is smooth and neat, with no uneven or uneven parts.

Cut edges are straight and neat, with no jagged or irregular cutting edges.

No burrs, ensuring safe handling and installation.

There is no exposed aluminum honeycomb core on the front and back, which means that the decorative aluminum plate completely covers the honeycomb structure.

2. Folding place

There are no obvious cracks at the folded edges, indicating that no shearing or excessive stretching occurred during processing.

3.Others

The product has no degumming, and the bonding strength between the honeycomb structure and the outer aluminum plate is good, without delamination or falling off.

These standards ensure the appearance quality and functional performance of marine aluminum honeycomb panels, which are suitable for various decorative and structural applications, such as exterior walls, decoration, ship interiors, etc.

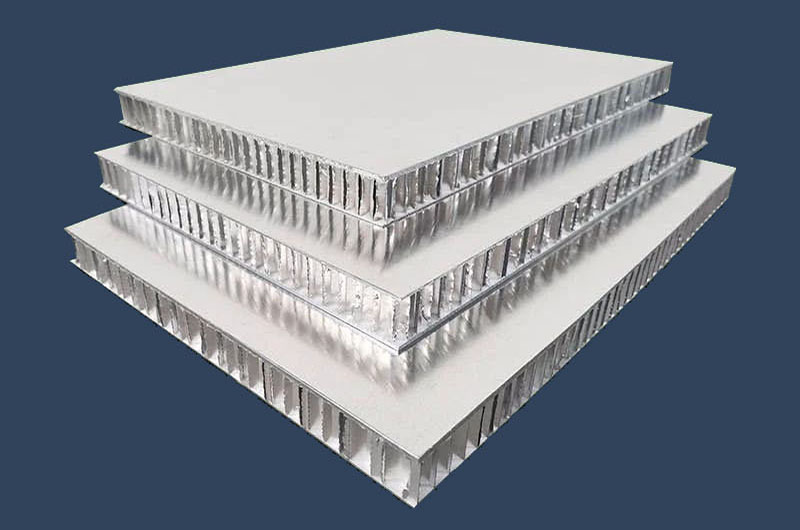

Main Alloy of Marine grade aluminum honeycomb panel structure

Among marine-grade aluminum honeycomb panels, aluminum alloy honeycomb panels are aluminum composite panels composed of two cover plates and an aluminum honeycomb core.

5052 5083 Marine aluminum honeycomb panel of panel

Panels are typically made from marine-grade aluminum alloy to ensure corrosion resistance and strength.

Common alloys include 5052, 5083 and 6061 because of their excellent corrosion resistance and mechanical properties.

These alloys provide durability and withstand harsh marine environments, including exposure to salt water and moisture.

3003 5052 Marine aluminum honeycomb panel of honeycomb core

Honeycomb cores are typically made from aluminum foil formed into a hexagonal pattern.

The honeycomb core is preferably an aluminum alloy with good formability and a high strength-to-weight ratio.

Commonly used alloys include 3003 and 5052 because of their excellent formability and lightweight properties.

The hexagonal honeycomb structure provides superior strength and rigidity while minimizing weight, helping to improve the overall performance of the panel.

By combining these different types of aluminum in a sandwich structure, marine-grade aluminum honeycomb panels achieve a balance of strength, corrosion resistance and lightweight properties, making them ideal for a variety of marine applications.

Marine grade aluminum honeycomb plate applications

Due to its light weight, high strength, good rigidity, high flatness, and non-deformation, aluminum honeycomb panels can be used to manufacture ship interior panels such as control panels, bulkheads, ceiling pads, luggage racks, toilet units, washrooms, and floor panels. , four-corner doors and isolation hatches, as well as external components such as fenders, entire car bodies, compartment panels, etc.

- Bulkheads and Partitions: Used to separate different parts of a vessel, provide structural support and maintain separation.

- Flooring and Decoration: Provides lightweight and durable flooring solutions that help improve the overall stability of the vessel.

- Ceiling and wall panels: used for interior and exterior cladding, combining aesthetics and functionality.

- Doors and hatches: Made to be lightweight yet strong, doors and hatches ensure safety and convenience on board.

- Bunks (Bulkheads): used to separate different areas inside the ship to ensure the strength and stability of the ship's structure.

- Hatches: Used as hatch covers or cargo hatch covers for ships, providing access holes that are easy to open and close, and ensuring tightness and structural strength.

- Deck: As the deck surface material of the ship, it provides a comfortable walking surface and can withstand various loads during the ship's operation at sea.

- Partitions: used to divide the interior of the ship into different areas or compartments, helping to organize and manage the interior space of the ship.

- Shipboard Elevators: As structural materials for shipboard elevators, they are used to support and protect elevator equipment, while reducing the total weight and providing necessary strength and stability.

- Longitudinal Beams: used as part of the hull structure to provide longitudinal support and reinforcement to ensure the stability and safety of the hull during maritime operations.

Marine grade aluminum honeycomb plate production process

- Cut aluminum coils into different sizes

- Apply protective film

- flat pressure

- polishing

- Engraving/beveling/bending if necessary

- Composite with honeycomb core

- Trim if necessary

- Package