Marine grade aluminum pipe tube

Aluminum tubes used in marine applications are commonly used in a variety of ship structures, including frames, railings, mast supports and other components, where lightweight, corrosion-resistant materials are critical for long-term performance and safety.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

A cylindrical hollow profile made from marine-grade aluminum, commonly used in shipbuilding and marine structures due to its corrosion resistance and high strength. It is often utilized in pipelines, railings, and frameworks.

Marine grade aluminum pipe refers to aluminum pipe designed and manufactured specifically for use in marine environments. Made of aluminum alloy, these tubes are engineered to withstand the harsh conditions typically encountered in marine applications, such as exposure to salt water, moisture and corrosive elements.

Aluminum tubes used in marine applications are commonly used in a variety of ship structures, including frames, railings, mast supports and other components, where lightweight, corrosion-resistant materials are critical for long-term performance and safety.

These pipes and tubes are often manufactured to meet specific industry standards and may have additional treatments or coatings to increase their resistance to corrosion and other environmental factors.

Marine-grade aluminum pipes are typically made from 5xxx and 6xxx series alloys, including:

- 5083, 5086, 5383, 5059: Non-heat-treatable alloys with high corrosion resistance and weldability, ideal for structural components such as hulls and decks.

- 6061, 6082, 6005A: Heat-treatable alloys (T5/T6 temper) with medium to high strength, resistance to stress cracking, and good machinability, suitable for fittings and frameworks.

- 6463: Used for polished anodized tubes, commonly found in aesthetically pleasing marine structures such as T-tops and railings.

5083 is renowned for its excellent resistance to general seawater corrosion, crevice corrosion, and exfoliation, making it a mainstay material for hulls and piping systems.

Features of Marine Aluminum Tube

- Corrosion Resistance: Capable of withstanding salt spray and moisture in marine environments, extending its service life.

- High Strength: Aluminum alloys offer an excellent strength-to-weight ratio, allowing the cylindrical hollow profile to provide sufficient strength while maintaining a low weight. This helps enhance the overall efficiency and performance of ships and marine structures.

- Machinability: Aluminum alloy materials are easy to machine, allowing for cutting, welding, and forming as needed to meet different design and engineering requirements.

Marine Aluminum Tube Typical Specifications

Marine Aluminum Tube Specifications Measurement Chart

| Diameter (D) mm | 22 | 35 | 45 | 50 | 60 | 70 | 80 | 108 | 120 | 130 |

| Thickness (T) mm | 3 | 5 | 4 | 3 | 6 | 5 | 5 | 8 | 5 | 10 |

Marine-grade aluminum pipes are designed to resist seawater corrosion while maintaining sufficient strength and manufacturability. They are available in both seamless and welded types, with diameters ranging from small hydraulic lines to structural pipes with nominal pipe sizes (NPS) of several inches. Typical wall thickness follows standard specifications (e.g., Sch 40, Sch 80), with lengths ranging from 1 meter to 8 meters, and custom cut-to-length options available upon request.

Marine grade aluminum pipe tube Surface Treatments and Certifications

- Anodized surface: Bright dipped anodizing for corrosion resistance and stainless-steel-like aesthetics.

- Certifications: Compliant with maritime safety standards of BV, DNV, ABS, and Lloyd’s.

Marine grade aluminum pipe tube Standards and Specifications

ASTM B241: Covers extruded seamless and welded 5083 pipes. ASTM B210: Defines seamless pipes of 5086 alloy. ASTM B221: Governs extruded pipes in various shapes for 6061 alloy. International equivalents: EN AW-5083, EN AW-5086, EN AW-6061; UNS A95083, A95086, A96061.

Marine Aluminum Tube Alloys

Marine-grade aluminum tubes generally use alloys 6061, 6063, and 6082. These aluminum tubes each have unique advantages in marine and ocean environments.

- 6061 aluminum tubes are known for their high strength and good corrosion resistance, making them suitable for heavy-duty structures and load-bearing applications.

- 6063 aluminum tubes excel in surface finishing and machinability, making them ideal for decorative and lightweight structures.

- 6082 aluminum tubes offer high strength and corrosion resistance, suitable for applications requiring high load-bearing capacity and durability.

6061 Marine Grade Aluminum Tube

- Strength and Toughness: The 6061 alloy provides high strength and good toughness, especially in the T6 temper, exhibiting excellent mechanical properties.

- Corrosion Resistance: This aluminum alloy demonstrates good corrosion resistance in most marine environments, making it suitable for salt spray conditions.

Applications

- Structural Piping: Widely used in structural piping systems for ships and marine platforms, capable of withstanding high loads and resisting harsh environmental conditions.

- Frames and Supports: Used in the manufacturing of various frames and support structures, such as hull supports and platform frames, offering an excellent strength-to-weight ratio.

- Other Applications: Due to its excellent machinability, 6061 aluminum tubes can also be used to create various custom parts and fittings.

6063 Marine Grade Aluminum Tube

- Strength and Machinability: The 6063 alloy typically has lower strength but excellent machinability and surface finishing properties, making it an ideal choice for aluminum tubes.

- Corrosion Resistance: In marine environments, 6063 aluminum tubes also exhibit good corrosion resistance, suitable for applications exposed to moisture and salt spray.

Applications

- Decorative Piping: 6063 aluminum tubes are commonly used in applications that require high surface finish and decorative effects, such as railings, handrails, and decorative structures on ships.

- Lightweight Structures: Suitable for lightweight structures and non-load-bearing applications, such as interior frames and fittings.

- Other Applications: Also used in manufacturing parts requiring a good surface finish and appearance.

6082 Marine Grade Aluminum Tube

- Strength and Durability: The 6082 alloy is one of the stronger aluminum alloys, especially in the T6 temper, providing excellent mechanical properties.

- Corrosion Resistance: Exhibits good corrosion resistance in marine environments, suitable for applications exposed to salt spray and moisture over extended periods.

Applications

- Heavy-Duty Structural Piping: Widely used in heavy-duty structural piping systems that require high strength and corrosion resistance, such as hull supports, platform structures, and frames.

- Engineering Applications: Suitable for engineering applications requiring high strength and durability, including main structural components of marine platforms.

- Other Applications: Due to its high strength and excellent corrosion resistance, it can also be used to manufacture other critical components and fittings.

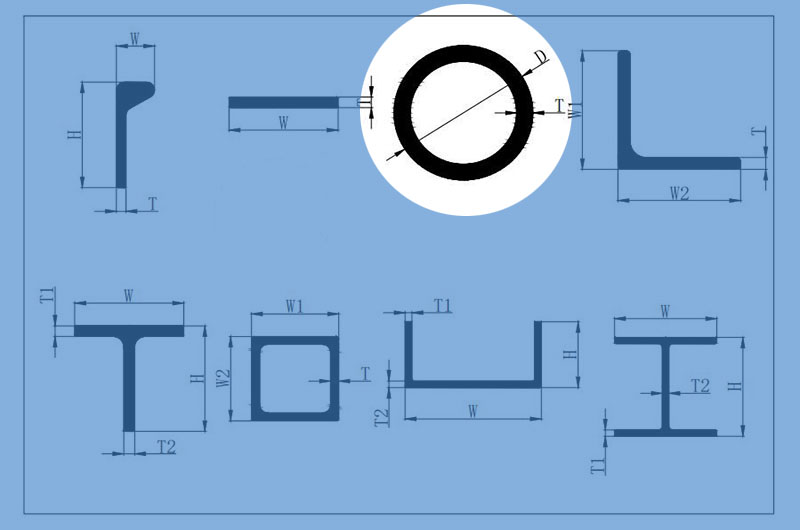

What shapes are used for marine grade aluminum pipe tubes?

Marine-grade aluminum tubing comes in a variety of shapes and sizes, depending on its intended use and application.

- Marine grade aluminum round tubes: This is the most common shape of aluminum tubes, providing strength and versatility for a variety of marine applications such as handrails, boat frames, and support structures.

- Marine grade aluminum square tubes: Square aluminum tubes offer greater rigidity and are often used in applications where strength and stability are critical, such as boat trailers, support beams, and railing systems.

- Marine grade aluminum rectangular tubes: Similar to square tubes, rectangular aluminum tubes offer strength and stability, but have a different cross-sectional shape. They are commonly used in marine building frames, support structures and shipbuilding.

Marine Aluminum Tube Chemical Composition

| Element | 6061 Aluminum Alloy | 6063 Aluminum Alloy | 6082 Aluminum Alloy |

| Aluminum (Al) | Remainder | Remainder | Remainder |

| Silicon (Si) | 0.40-0.80% | 0.20-0.60% | 0.70-1.30% |

| Iron (Fe) | 0.70% Max | 0.35% Max | 0.50% Max |

| Copper (Cu) | 0.15-0.40% | 0.10% Max | 0.10-0.40% |

| Manganese (Mn) | 0.15-0.40% | 0.10% Max | 0.40-0.70% |

| Magnesium (Mg) | 0.80-1.20% | 0.45-0.90% | 0.60-1.20% |

| Chromium (Cr) | 0.04-0.35% | 0.10% Max | 0.25% Max |

| Zinc (Zn) | 0.25% Max | 0.10% Max | 0.10% Max |

| Titanium (Ti) | 0.15% Max | 0.10% Max | 0.10% Max |

| Lead (Pb) | 0.15% Max | 0.10% Max | 0.10% Max |

Common Marine Grade Aluminum Pipe Alloys from Haomei

The most widely used alloys for marine grade aluminum pipes are 5083, 5086, and 6061. These alloys are chosen because they provide a balance between corrosion resistance, strength, and formability.

- 5083 offers the best seawater resistance among non-heat-treatable alloys.

- 5086 has slightly lower strength but better pitting resistance.

- 6061 provides moderate strength, is heat-treatable, and has excellent weldability.

All three alloys comply with ASTM standards (B241, B210, and B221, respectively), and are available in seamless or welded pipe forms with various tempers and wall thicknesses. Their manufacturing processes (extrusion, drawing) and finishing treatments (anodizing, polishing) further enhance their durability in harsh marine environments, making them ideal for use in ship and offshore platform piping systems, hydraulic lines, structural tubing, and handrails.

| Item | 5083 Aluminum Alloy | 5086 Aluminum Alloy | 6061 Aluminum Alloy |

| Corrosion Resistance | Excellent resistance to general seawater corrosion, crevice corrosion, and exfoliation; suitable for long-term seawater exposure | Superior pitting resistance; suitable for immersion zones, splash zones, and moist environments | Good, though not as pitting-resistant as 5xxx series; significantly improved after anodizing |

| Manufacturing Standard | ASTM B241: Seamless or welded extruded pipe; cold working can improve strength | ASTM B210: Seamless pipe; suitable for MIG/TIG or FSW welding with minimal strength loss | ASTM B221: Extruded pipe; good weldability and machinability |

| Surface Treatment | Typically resists seawater corrosion without the need for anodizing | Naturally corrosion-resistant; suitable for bare use | Anodizing significantly enhances corrosion resistance and aesthetics |

| Typical Applications | Hull structures, fuel and ballast piping, offshore platforms, pressure vessels | Hulls, decks, gangways, hydraulic lines, offshore platform structures | Ship handrails, masts, struts, yacht structures, lightweight hulls, transfer pipelines |

Marine Grade Aluminum Pipe Tube Seawater Corrosion Resistance

Marine alloys resist uniform corrosion, pitting, and stress corrosion cracking:

- 5083: Minimal corrosion even at temperatures up to 65°C; capable of withstanding decades of splash and immersion.

- 5086: Pitting depth <1 mm after long-term exposure; negligible strength loss after 5 years of full immersion.

- 6061: Requires anodizing to achieve optimal pitting resistance in seawater; otherwise suitable for atmospheric exposure with occasional splashing.

Marine Aluminum Tube Applications

- Pipeline Systems: Cylindrical hollow profiles are commonly used to manufacture pipeline systems on ships and marine platforms. These pipelines are used to transport liquids and gases or serve as structural support components.

- Railings and Handrails: Due to their corrosion resistance and structural strength, these profiles are also used to manufacture railings and handrails, providing safety while ensuring durability and long-term stability.

- Frames and Support Structures: Cylindrical hollow profiles play a crucial role in frames and support structures, especially in applications requiring lightweight and high strength. They can be used to construct platforms, support frames, and other structural components.

- Custom Devices: In certain cases, cylindrical hollow profiles can be customized according to specific needs to create various special devices and structural components.

Haomei Marine Aluminum Tube Stock

| Product Description ( D x T ) mm | D (Diameter) mm | T (Wall thickness) mm | Brand | Weight per meter (kg/m) | Previous period inventory |

| 20 X 3 Aluminum 6082 T6 Round Tube | 20 | 3 | 6082 T6 | 0.436 | 333.5 |

| 22 X 3 Aluminum 6063 T6 Round Tube | 22 | 3 | 6063 T6 | 0.487 | 155 |

| 22 X 3 Aluminum 6082 T6 Round Tube | 22 | 3 | 6082 T6 | 0.487 | 190 |

| 25 X 3 Aluminum 6082 T6 Round Tube | 25 | 3 | 6082 T6 | 0.564 | 192.5 |

| 25 X 3 Aluminum 6061 T6 Round Tube | 25 | 3 | 6061 T6 | 0.564 | 155 |

| 27 X 2.87 Aluminum 6082 T6 Round Tube | 27 | 2.87 | 6082 T6 | 0.592 | 369.5 |

| 30 X 3 Aluminum 6082 T6 Round Tube | 30 | 3 | 6082 T6 | 0.692 | 421.5 |

| 30 X 4 Aluminum 6082 T6 Round Tube | 30 | 4 | 6082 T6 | 0.889 | 94 |

| 32 X 3 Aluminum 6063 T6 Round Tube | 32 | 3 | 6063 T6 | 0.743 | 85 |

| 32 X 3 Aluminum 6082 T6 Round Tube | 32 | 3 | 6082 T6 | 0.743 | 278 |

| 32 X 4 Aluminum 6082 T6 Round Tube | 32 | 4 | 6082 T6 | 0.957 | 341 |

| 34 X 3 Aluminum 6082 T6 Round Tube | 34 | 3 | 6082 T6 | 0.795 | 245 |

| 34 X 4 Aluminum 6082 T6 Round Tube | 34 | 4 | 6082 T6 | 1.025 | 302 |

| 34 X 5 Aluminum 6082 T6 Round Tube | 34 | 5 | 6082 T6 | 1.239 | 334 |

| 34 X 8 Aluminum 6082 T6 Round Tube | 34 | 8 | 6082 T6 | 1.777 | 94 |

| 35 X 3 Aluminum 6082 T6 Round Tube | 35 | 3 | 6082 T6 | 0.82 | 225.5 |

| 35 X 5 Aluminum 6082 T6 Round Tube | 35 | 5 | 6082 T6 | 1.282 | 64 |

| 38 X 3 Aluminum 6082 T6 Round Tube | 38 | 3 | 6082 T6 | 0.897 | 9 |

| 38 X 4 Aluminum 6082 T6 Round Tube | 38 | 4 | 6082 T6 | 1.162 | 269 |

| 40 X 4 Aluminum 6082 T6 Round Tube | 40 | 4 | 6082 T6 | 1.231 | 210.5 |

| 40 X 8 Aluminum 6082 T6 Round Tube | 40 | 8 | 6082 T6 | 2.188 | 200 |

| 42 X 3 Aluminum 6082 T6 Round Tube | 42 | 3 | 6082 T6 | 1 | 455 |

| 42 X 3.5 Aluminum 6082 T6 Round Tube | 42 | 3.5 | 6082 T6 | 1.151 | 251 |

| 42 X 3.5 Aluminum 6063 T6 Round Tube | 42 | 3.5 | 6063 T6 | 1.151 | 53 |

| 42 X 4 Aluminum 6082 T6 Round Tube | 42 | 4 | 6082 T6 | 1.299 | 131 |

| 45 X 4 Aluminum 6082 T6 Round Tube | 45 | 4 | 6082 T6 | 1.401 | 56 |

| 48 X 3 Aluminum 6082 T6 Round Tube | 48 | 3 | 6082 T6 | 1.154 | 123.5 |

| 48 X 4 Aluminum 6082 T6 Round Tube | 48 | 4 | 6082 T6 | 1.504 | 81 |

| 48 X 5 Aluminum 6082 T6 Round Tube | 48 | 5 | 6082 T6 | 1.837 | 151.5 |

| 50 X 3 Aluminum 6082 T6 Round Tube | 50 | 3 | 6082 T6 | 1.205 | 155.5 |

| 50 X 4 Aluminum 6082 T6 Round Tube | 50 | 4 | 6082 T6 | 1.572 | 119 |

| 50 X 4.5 Aluminum 6082 T6 Round Tube | 50 | 4.5 | 6082 T6 | 1.75 | 66.67 |

| 51 X 5 Aluminum 6082 T6 Round Tube | 51 | 5 | 6082 T6 | 1.965 | 88.667 |

| 60 X 3 Aluminum 6082 T6 Round Tube | 60 | 3 | 6082 T6 | 1.461 | 24 |

| 60 X 3 Aluminum 6082 T6 Round Tube | 60 | 3 | 6082 T6 | 1.461 | 76 |

| 60 X 4 Aluminum 6082 T6 Round Tube | 60 | 4 | 6082 T6 | 1.914 | 89 |

| 60 X 5 Aluminum 6082 T6 Round Tube | 60 | 5 | 6082 T6 | 2.35 | 94.5 |

| 60 X 6 Aluminum 6082 T6 Round Tube | 60 | 6 | 6082 T6 | 2.769 | 62.5 |

| 60 X 8 Aluminum 6082 T6 Round Tube | 60 | 8 | 6082 T6 | 3.555 | 112 |

| 65 X 4 Aluminum 6082 T6 Round Tube | 65 | 4 | 6082 T6 | 2.085 | 186 |

| 70 X 6 Aluminum 6082 T6 Round Tube | 70 | 6 | 6082 T6 | 3.281 | 18 |

| 75 X 4 Aluminum 6082 T6 Round Tube | 75 | 4 | 6082 T6 | 2.427 | 28 |

| 75 X 4 Aluminum 6082 T6 Round Tube | 75 | 4 | 6082 T6 | 2.427 | 80 |

| 75 X 7 Aluminum 6082 T6 Round Tube | 75 | 7 | 6082 T6 | 4.067 | 71 |

| 76 X 5 Aluminum 6082 T6 Round Tube | 76 | 5 | 6082 T6 | 3.034 | 116 |

| 76 X 6 Aluminum 6082 T6 Round Tube | 76 | 6 | 6082 T6 | 3.589 | 87.5 |

| 80 X 4 Aluminum 6082 T6 Round Tube | 80 | 4 | 6082 T6 | 2.598 | 21 |

| 80 X 5 Aluminum 6082 T6 Round Tube | 80 | 5 | 6082 T6 | 3.181 | 3.4 |

| 80 X 8 Aluminum 6082 T6 Round Tube | 80 | 8 | 6082 T6 | 4.922 | 57 |

| 80 X 10 Aluminum 6082 T6 Round Tube | 80 | 10 | 6082 T6 | 5.982 | 33 |

| 85 X 5 Aluminum 6082 T6 Round Tube | 85 | 5 | 6082 T6 | 3.418 | 115 |

| 89 X 4.05 Aluminum 6082 T6 Round Tube | 89 | 4.05 | 6082 T6 | 2.94 | 74.5 |

| 89 X 5 Aluminum 6082 T6 Round Tube | 89 | 5 | 6082 T6 | 3.589 | 101 |

| 89 X 8 Aluminum 6082 T6 Round Tube | 89 | 8 | 6082 T6 | 5.537 | 76 |

| 90 X 6 Aluminum 6082 T6 Round Tube | 90 | 6 | 6082 T6 | 4.307 | 97 |

| 90 X 8 Aluminum 6082 T6 Round Tube | 90 | 8 | 6082 T6 | 5.606 | 49.5 |

| 90 X 10 Aluminum 6082 T6 Round Tube | 90 | 10 | 6082 T6 | 6.836 | 15 |

| 100 X 4 Aluminum 6082 T6 Round Tube | 100 | 4 | 6082 T6 | 3.281 | 0 |

| 100 X 5 Aluminum 6082 T6 Round Tube | 100 | 5 | 6082 T6 | 4.059 | 20.5 |

| 100 X 10 Aluminum 6082 T6 Round Tube | 100 | 10 | 6082 T6 | 7.691 | 25 |

| 101.6 X 6.35 Aluminum 6082 T6 Round Tube | 101.6 | 6.35 | 6082 T6 | 5.168 | 0 |

| 102 X 6 Aluminum 6082 T6 Round Tube | 102 | 6 | 6082 T6 | 4.922 | 37.5 |

| 108 X 4 Aluminum 6082 T6 Round Tube | 108 | 4 | 6082 T6 | 3.555 | 86 |

| 108 X 8 Aluminum 6082 T6 Round Tube | 108 | 8 | 6082 T6 | 6.836 | 48 |

| 108 X 8 Aluminum 6061 T6 Round Tube | 108 | 8 | 6061 T6 | 6.836 | 28 |

| 110.3 X 5 Aluminum 6082 T6 Round Tube | 110.3 | 5 | 6082 T6 | 4.499 | 76.5 |

| 110 X 10 Aluminum 6063 T6 Round Tube | 110 | 10 | 6063 T6 | 8.545 | 4 |

| 114.3 X 6 Aluminum 6082 T6 Round Tube | 114.3 | 6 | 6082 T6 | 5.553 | 32.5 |

| 114.3 X 8.6 Aluminum 6082 T6 Round Tube | 114.3 | 8.6 | 6082 T6 | 7.768 | 57 |

| 115 X 9 Aluminum 6082 T6 Round Tube | 115 | 9 | 6082 T6 | 8.152 | 7 |

| 120 X 5 Aluminum 6082 T6 Round Tube | 120 | 5 | 6082 T6 | 4.913 | 65 |

| 120 X 6 Aluminum 6082 T6 Round Tube | 120 | 6 | 6082 T6 | 5.845 | 17.38 |

| 120 X 10 Aluminum 6082 T6 Round Tube | 120 | 10 | 6082 T6 | 9.399 | 44 |

| 125 X 3 Aluminum 6082 T6 Round Tube | 125 | 3 | 6082 T6 | 3.128 | 151.5 |

| 127 X 19 Aluminum 6082 T6 Round Tube | 127 | 19 | 6082 T6 | 17.535 | 4 |

| 130 X 5 Aluminum 6082 T6 Round Tube | 130 | 5 | 6082 T6 | 5.341 | 34 |

| 130 X 10 Aluminum 6082 T6 Round Tube | 130 | 10 | 6082 T6 | 10.254 | 6 |

| 140 X 6 Aluminum 6082 T6 Round Tube | 140 | 6 | 6082 T6 | 6.87 | 12.5 |

| 140 X 10 Aluminum 6082 T6 Round Tube | 140 | 10 | 6082 T6 | 11.109 | 18 |

| 150 X 5 Aluminum 6082 T6 Round Tube | 150 | 5 | 6082 T6 | 6.195 | 8.5 |

| 150 X 10 Aluminum 6082 T6 Round Tube | 150 | 10 | 6082 T6 | 11.88 | 3 |

| 150 X 12 Aluminum 6082 T6 Round Tube | 150 | 12 | 6082 T6 | 14.151 | 13.467 |

| 160 X 10 Aluminum 6082 T6 Round Tube | 160 | 10 | 6082 T6 | 12.818 | 27 |

| 170 X 7 Aluminum 6082 T6 Round Tube | 170 | 7 | 6082 T6 | 9.75 | 38 |

| 170 X 10 Aluminum 6082 T6 Round Tube | 170 | 10 | 6082 T6 | 13.672 | 18 |

| 180 X 15 Aluminum 6082 T6 Round Tube | 180 | 15 | 6082 T6 | 21.14 | 13 |

| 190 X 11 Aluminum 6082 T6 Round Tube | 190 | 11 | 6082 T6 | 16.825 | 20.5 |

| 190 X 12 Aluminum 6082 T6 Round Tube | 190 | 12 | 6082 T6 | 18.96 | 19 |

| 190 X 20 Aluminum 6082 T6 Round Tube | 190 | 20 | 6082 T6 | 29.053 | 10 |

| 210 X 5 Aluminum 6082 T6 Round Tube | 210 | 5 | 6082 T6 | 10.036 | 39 |

| 216 X 12.7 Aluminum 6082 T6 Round Tube | 216 | 12.7 | 6082 T6 | 22.063 | 16 |

| 280 X 10 Aluminum 6082 T6 Round Tube | 280 | 10 | 6082 T6 | 23.072 | 5.5 |

Marine Grade Aluminum Pipe Tube Manufacturing Process

- Extrusion Forming: Pure aluminum or aluminum alloy is processed into hollow tubes through hot extrusion, with uniform wall thickness and customizable cross-sectional shapes.

- Heat Treatment Strengthening: For example, 6082 aluminum alloy significantly increases in strength after T6 heat treatment, suitable for high-load components.

- Surface Treatment: Anodizing or coating processes can further enhance weather resistance and aesthetics.

Manufacturing and Finishing

- Extrusion and Drawing: Tubes can be hot-extruded first and then cold-drawn to achieve seamless products with strict tolerances.

- Welding: All alloys are suitable for arc welding; the 5xxx series retains about 90% of its strength in the weld zone, while 6061 requires post-weld aging to restore strength.

- Anodizing: A common process for 6061; improves surface hardness and corrosion resistance without masking the alloy’s natural color.

- Surface Treatment: Polishing, mechanical shot peening, or coatings (epoxy resin, marine-grade coatings) can further extend service life.

Marine Grade Aluminum Pipe Tube Advantage Comparison

Compared to traditional marine steel pipes, aluminum pipes offer the same strength with lighter weight and avoid the frequent maintenance issues caused by steel corrosion. Additionally, aluminum pipes have lower processing costs and higher overall efficiency over their lifecycle.

Advantages Over Other Materials

- Lightweight: Compared with stainless steel, it reduces vessel weight and improves fuel efficiency.

- Corrosion Resistance: Magnesium and chromium additives in alloys such as 5083/5086 prevent seawater corrosion.

- Weldability and Formability: Compatible with TIG/MIG welding and cold forming processes.

Marine Grade Aluminum Pipe Tube Selection Criteria

- Corrosive Environment: For continuous immersion, select 5083 or 5086 alloy; for splash zones, choose anodized 6061 alloy.

- Strength Requirements: For higher mechanical load capacity, use 5xxx series in H temper or 6061 alloy in T6 temper.

- Manufacturing Needs: Formability varies among alloys—5083/5086 alloys use O temper for bending applications; H32 temper for straight tube applications; 6061-O alloy is used for deep drawing applications.

- Cost and Availability: 5xxx series alloys typically cost more than 6061 alloys; check local mill inventory for delivery times.