Marine grade aluminum diamond plate

Marine grade aluminum diamond plate, also known as checker plate or tread plate, is a type of aluminum sheet material that features a raised diamond pattern on one side. This pattern provides excellent slip resistance, making it suitable for applications where safety and traction are crucial, such as on boat decks, docks, and other marine environments.

Aluminum diamond plate is lightweight, durable, and easy to clean, making it a popular choice for marine applications where exposure to saltwater and harsh weather conditions is common. It offers a combination of strength and corrosion resistance that makes it ideal for use in marine vessels, offshore platforms, and other maritime structures.

Marine grade aluminum plate is a specially designed aluminum plate that is widely used in various large and small vessels, including passenger ships, cruise ships, motor boats, high-speed missile boats, patrol boats, destroyers and fishing boats. Its original design is mainly to provide good anti-slip effect and excellent rust resistance. It is also lighter in weight than traditional materials such as steel.

The design of this diamond plate is not only for aesthetics, but more importantly for safety considerations on the ship. When sailing at sea, the hull often faces slippery conditions, and the rhombus pattern can provide additional friction, reducing the risk of people and cargo slipping, thereby enhancing safety on board.

In addition, marine-grade aluminum diamond plates are also favored for their excellent corrosion resistance. In corrosive environments such as sea water and salt spray, traditional metals are often easily eroded, leading to rust and corrosion, thus affecting the service life and safety of the hull. Aluminum diamond plates can effectively resist these corrosion factors, extend the service life of the hull, and reduce maintenance and repair costs.

Haomei Aluminum Marine grade aluminum diamond plate specifications

| Name | Aluminum Diamond Plate |

| Aluminum Diamond Plate Alloy | 5052, 5083, 5086 |

| Other Names | Diamond aluminum plate, diamond tread aluminum sheet, Embossed Aluminum diamond plate, Durable Aluminum diamond plate, Aluminum diamond tread Plate |

| Aluminum Diamond Plate Thickness | 1.2-8mm |

| Aluminum Diamond Plate Width | 100-1850 mm |

| Aluminum Diamond Plate Length | 500-16000 mm |

| Aluminum Diamond Plate Production Process | Hot rolling, embossing. |

| Aluminum Diamond Plate Surface Treatment | Mill finish, Bright finish |

| Aluminum Diamond Plate Color | Black, sliver, blue, Red, etc. (Customizable) |

| Aluminum Diamond Plate Delivery Type | Sheet, Plate, Roll, Strip |

| Aluminum Diamond Plate Surface Protection | With membrane or without membrane, can be customized according to requirements |

| Aluminum Diamond Plate Packaging | Wooden frame/wooden box packaging, steel belt fixed |

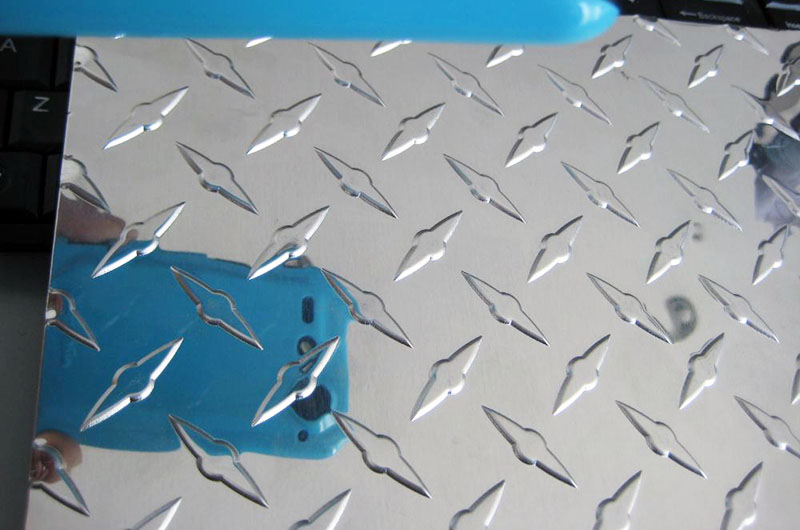

Haomei Marine aluminum diamond plate product display

Main Alloys of marine grade aluminum diamond plate

5052 and 5086 Marine Grade Aluminum Diamond Plate are a popular choice for marine applications due to their excellent corrosion resistance and durability.

5052 Marine Grade Aluminum Diamond Plate

- Alloy composition: 5052 aluminum alloy uses aluminum as the main element and contains small amounts of other elements, including magnesium and chromium.

- Properties: 5052 aluminum has good weldability, formability and excellent corrosion resistance, especially in marine environments. It has strong resistance to salt water corrosion and is suitable for use on ships, ship decks and other marine structures.

- Applications: 5052 Marine Grade Aluminum Diamond Plate is commonly used in boat hulls, ship decks, dock surfaces, gangways and other marine applications where corrosion resistance and durability are critical.

5086 Marine Grade Aluminum Diamond Plate

- Alloy Composition: 5086 Aluminum alloy is primarily composed of aluminum with magnesium and small amounts of other elements such as manganese and chromium.

- Properties: 5086 aluminum has high strength and excellent corrosion resistance, especially in salt water environments. It also has good weldability and formability, making it suitable for a variety of marine applications.

- Applications: 5086 Marine Grade Aluminum Diamond Plate is widely used in ships, hulls, offshore platforms and other marine structures where strength, corrosion resistance and durability are critical. Due to its resistance to chemical corrosion, it is also commonly used in tank trucks and chemical equipment.

Both alloys feature a diamond plate pattern that provides extra traction and slip resistance, making them ideal for floors and other surfaces in marine environments where safety is a concern. Additionally, both alloys can be easily fabricated and processed to meet the specific design requirements of marine applications.

5052 and 5086 aluminum alloys are commonly used in the construction of ships, docks, offshore platforms and other marine structures where durability and corrosion resistance are critical. The diamond plate pattern provides extra grip and traction, making it suitable for use on floors and other surfaces in marine environments.

Common sizes and thicknesses of marine grade aluminum diamond plate

Marine grade aluminum diamond plate thickness can be customized based on customer choices. Among them, 1/4" aluminum diamond plate is the most commonly used thickness. Below are common thicknesses of diamond pattern plates:

- 0.045" (3/64") Marine grade aluminum diamond plate

- 0.063" (1/16") Marine grade aluminum diamond plate

- 0.125" (1/8") Marine grade aluminum diamond plate

- 0.187" (3/16") Marine grade aluminum diamond plate

- 0.25" (1/4") Marine grade aluminum diamond plate

Marine-grade aluminum diamond plates not only have good anti-skid effects and anti-rust capabilities, but are also lightweight, making them an ideal choice for ship construction and maintenance, and can improve the safety and economy of ships.

Marine grade aluminum diamond plate advantages and disadvantages

Advantages of Marine Grade Aluminum Diamond Plate

- Corrosion Resistance: Marine-grade aluminum offers superior corrosion resistance compared to other materials, extending the life of marine structures.

- Lightweight: Its low density makes it an excellent choice for applications where weight reduction is required, such as ships and offshore platforms.

- ANTI-SLIP SURFACE: Raised diamond pattern provides enhanced traction and improved safety in slippery conditions.

- Low Maintenance: Aluminum requires minimal maintenance, reducing operating costs throughout the life of the marine structure.

- Recyclability: Aluminum is highly recyclable and contributes to the sustainability of the maritime industry.

Limitations of Marine Grade Aluminum Diamond Plate

- Cost: The upfront cost of marine-grade aluminum can be higher compared to other materials like steel or wood.

- Easily damaged: While durable, aluminum can easily develop dents and scratches, especially in high-traffic areas.

- Thermal Conductivity: Aluminum has high thermal conductivity, which may cause heat transfer in some applications.

- Galvanic Corrosion: Galvanic corrosion can occur when in contact with dissimilar metals in salt water environments, requiring proper insulation or the use of compatible materials.

- Limited load-bearing capacity: Although aluminum is strong, it has a lower load-bearing capacity compared to steel, which may limit its suitability for certain structural applications.

Marine grade aluminum diamond plate is a versatile material with excellent corrosion resistance, strength to weight ratio and traction properties, making it ideal for a variety of marine applications. Its unique combination of properties makes it the first choice for shipbuilding, offshore structures and marine equipment. While it has certain limitations, the advantages outweigh the disadvantages in many maritime scenarios. As the maritime industry continues to evolve, marine grade aluminum diamond plates remain at the forefront of innovation, contributing to safer, more efficient and sustainable marine structures.

Surface type of Marine aluminum diamond plate

Mill finish Marine aluminum diamond plate

Mill finish Marine aluminum diamond plate surface finish is the basic untreated surface of aluminum as it comes out of the rolling mill. It has a somewhat dull, matte appearance.

Bright Marine aluminum diamond plate

Features Highly reflective, the surface finish is polished to a high gloss, reflective surface, providing a bright, shiny appearance.

Anodized Marine aluminum diamond plate

Anodizing enhances the natural metallic look of aluminum and is available in a variety of color options. Anodizing creates a thick oxide layer that enhances the natural corrosion resistance of aluminum.

Chemical Composition of Marine grade aluminum diamond plate

| Alloy | 5052 | 5086 |

| Si | 0.25 | 0.4 |

| Fe | 0.4 | 0.5 |

| Cu | 0.1 | 0.1 |

| Mn | 0.1 | 0.20-0.7 |

| Mg | 2.2-2.8 | 3.5-4.5 |

| Cr | 0.15-0.35 | 0.05-0.25 |

| Ni | - | - |

| Zn | 0.1 | 0.25 |

| Ti | - | 0.15 |

| Ga | - | - |

| V | - | - |

| Each | 0.05 | 0.05 |

| Total | 0.15 | 0.15 |

| Alu | Remainder | Remainder |

Marine grade aluminum diamond plate manufacturing process

- 1. Alloying: Melting aluminum ingots and adding alloying elements such as magnesium to achieve desired properties.

- 2. Casting: Molten aluminum alloy is cast into slabs or billets of specific sizes.

- 3. Hot rolling: The slab is heated and passed through a series of rolling mills to reduce its thickness and shape it into coils or plates.

- 4. Cold rolling: Hot rolled coils are then cold rolled to further refine the thickness and improve surface finish.

- 5. Diamond pattern embossing: The cold-rolled sheet passes through an embossing roller with a diamond pattern to press the pattern onto one surface of the sheet.

- 6. Surface treatment: Optionally, the panels can undergo a surface treatment process, such as anodizing or painting, to provide additional protection and aesthetics.

Applications of Marine Grade Aluminum Diamond Plate

Marine grade aluminum diamond plate finds widespread applications in the maritime industry, including:

- Boat Decks: It is commonly used as flooring material on boat decks, providing a durable and non-slip surface for crew and passengers.

- Gangways: Ensure a firm stand on walkways and gangways.

- Stair treads: Used for steps and ladders on ships.

- Tool boxes and storage boxes: Durable and lightweight, perfect for storage solutions on board.

- Interior and exterior decoration: Enhance the beauty of your vessel while providing functional benefits.

- Bulkheads and Hulls: Aluminum diamond plate is utilized in the construction of bulkheads and hulls due to its corrosion resistance and lightweight.

- Dock and Pier Decking: It is employed for decking on docks, piers, and marinas, where exposure to saltwater necessitates corrosion-resistant materials.

- Offshore Platforms: Marine grade aluminum is used in the fabrication of offshore platforms, walkways, and gangways, where weight reduction and corrosion resistance are crucial.

- Marine Equipment: It is also used for various marine equipment such as ladders, handrails, and toolboxes due to its durability and low maintenance requirements.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

2 bar Marine grade aluminum tread plate

The surface of a 2 bar Marine grade aluminum tread plate is embossed with two raised bars or lines, forming a pattern that resembles a series of parallel ridges. 2 bar pattern provides enhanced grip and traction.

-

5 bar Marine grade aluminum tread plate

A 5 bar Marine grade aluminum tread plate is an aluminum plate with a patterned surface, featuring five raised bars or lines across the plate,This pattern provides enhanced traction and slip resistance.

More content of interest to readers