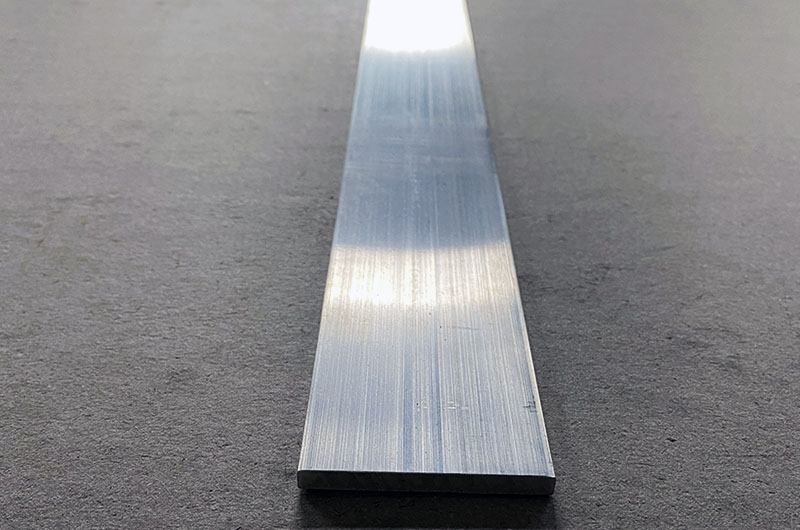

Marine Grade Flat Aluminum

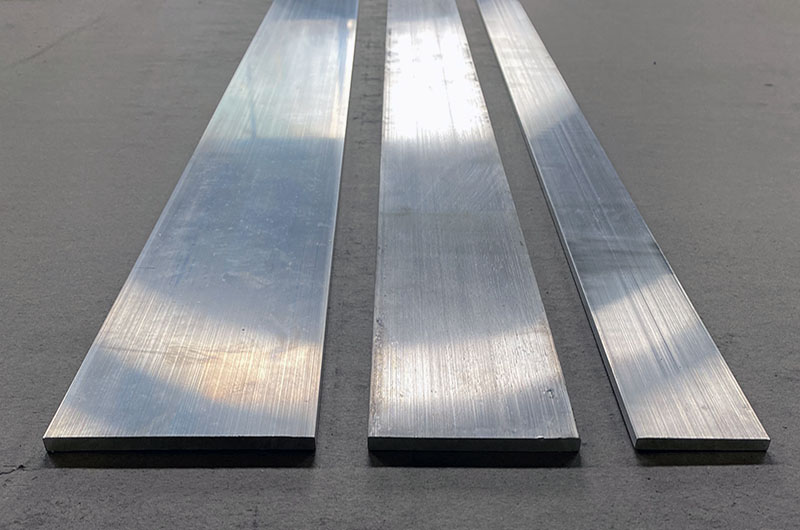

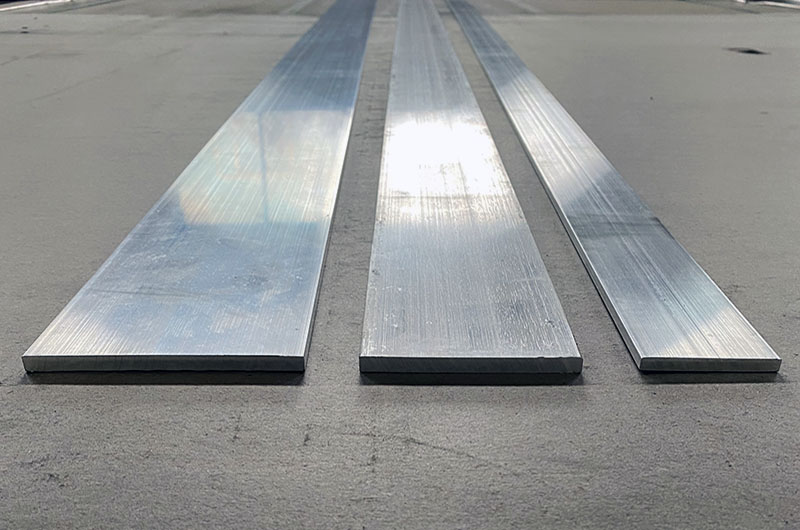

Marine Grade Flat Aluminum refers to flat, rectangular marine aluminum sheets or strips used in structural components, decks, and other flat surfaces on vessels.

Marine-grade flat aluminum is a specialized aluminum alloy material designed for marine environments, featuring excellent corrosion resistance, wear resistance, and mechanical strength. This type of aluminum is commonly used to manufacture hulls, decks, offshore platforms, and other marine structures that require high corrosion resistance. Marine-grade flat aluminum comes in the form of plates, strips, and profiles, primarily made from 5-series and 6-series aluminum alloys, known for their high corrosion resistance and good mechanical properties.

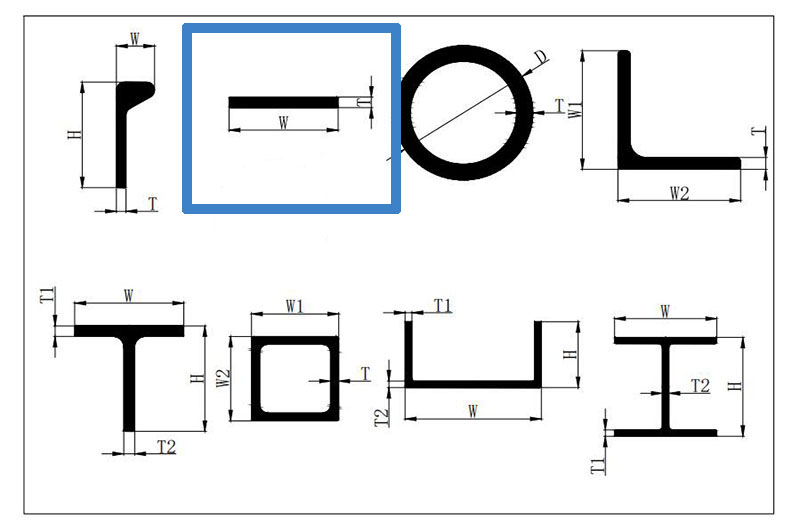

Specifications of Marine Grade Flat Aluminum

| Width (D) mm | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 180 | 250 |

| Thickness (T) mm | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 8 | 10 |

- Thickness: The thickness of marine-grade flat aluminum varies widely, ranging from 1 mm to several tens of millimeters, depending on the application requirements. Common thicknesses are 4 mm and 10 mm.

- Specifications: Based on usage requirements, flat aluminum can be produced in different specifications and sizes, such as wide plates, narrow plates, and profiles of specific shapes.

Main Alloys and Tempers of Marine Grade Flat Aluminum

5083 Marine Grade Flat Aluminum Bar

The 5083 aluminum alloy is one of the most representative marine-grade aluminum materials, offering excellent corrosion resistance and high strength, especially when exposed to saltwater environments. Common tempers include H111, H112, H116, and H321, and it is mainly used for manufacturing hulls and other structural components that require high strength and corrosion resistance.

5052 Marine Grade Flat Aluminum

The 5052 aluminum alloy is widely used in marine applications due to its good corrosion resistance and moderate strength. It is mainly used for manufacturing fuel tanks, pipes, and other components that require a certain level of pressure resistance. Common tempers include H32 and H34.

5454 Marine Grade Flat Aluminum Bar

The 5454 aluminum alloy is similar to 5083, offering excellent corrosion resistance and medium strength. It is commonly used in chemical storage tanks and other structures in marine environments.

6061 Marine Grade Flat Aluminum Bar

The 6061 aluminum alloy belongs to the 6-series and is known for its excellent machinability and high strength. It is commonly used for manufacturing marine accessories and structural components, with the most common temper being T6.

6082 Marine Grade Flat Aluminum Bar

The 6082 aluminum alloy is similar to 6061 but offers higher mechanical strength and good corrosion resistance. It is suitable for manufacturing structural support materials for hulls and other applications, with the common temper being T6.

Applications of Marine Grade Flat Aluminum

- 1. Shipbuilding: Used in the construction of hulls, decks, and other structural components. Due to its excellent corrosion resistance and high strength, it is particularly suitable for structures exposed to seawater for extended periods.

- 2. Offshore Platforms: Used in the construction of offshore platforms that require high strength and durability, maintaining stable performance in harsh marine environments.

- 3. Chemical Storage Tanks: Used for storing and transporting chemicals, especially those operating in marine environments, requiring high corrosion resistance and structural stability.

Marine-grade flat aluminum holds an important position in marine engineering, shipbuilding, and other applications that require high strength and long service life due to its exceptional corrosion resistance and mechanical properties.

Marine-grade flat aluminum bars are widely used in marine engineering and shipbuilding for the manufacture of hull structures, masts, deck structures, offshore platforms, marine pipelines, subsea facilities, and various other components of marine engineering projects.

Haomei Marine Grade Flat Aluminum Inventory

| Product Name | Specifications (mm) | Brand | Mold No. | Weight per meter (kg/m) | Fixed length(m) | Previous period inventory |

| Flat Aluminum | LP25*3 | 6082-T6 | YH-HZ-LP25*3 | 0.203 | 6 | 400 |

| Flat Aluminum | LP30*3 | 6082-T6 | YH-HZ-LP30*3 | 0.244 | 6 | 464 |

| Flat Aluminum | LP16*4 | 6082-T6 | YH-HZ-LP16*4 | 0.175 | 6 | 800 |

| Flat Aluminum | LP25*4 | 6082-T6 | YH-HZ-LP25*4 | 0.272 | 6 | 556 |

| Flat Aluminum | LP30*4 | 6082-T6 | YH-HZ-LP30*4 | 0.326 | 6 | 968 |

| Flat Aluminum | LP40*3 | 6082-T6 | YH-HZ-LP40*3 | 0.326 | 6 | 251.5 |

| Flat Aluminum | BL40*4 | 6082-T6 | YH-HZ-LP40*4 | 0.435 | 6 | 751 |

| Flat Aluminum | LP60*4 | 6082-T6 | YH-HZ-LP60*4 | 0.653 | 6 | 169 |

| Flat Aluminum | LP60*4 | 6082-T6 | YH-HZ-LP60*4 | 0.653 | 10.12 | 286 |

| Flat Aluminum | LP60*4 | 6082-T6 | YH-HZ-LP60*4 | 0.653 | 12.12 | 174 |

| Flat Aluminum | LP80*4 | 6082-T6 | YH-HZ-LP80*4 | 0.871 | 6 | 135 |

| Flat Aluminum | BL50*4 | 6082-T6 | YH-HZ-LP50*4 | 0.543 | 6 | 471 |

| Flat Aluminum | BL40*5 | 6082-T6 | YH-HZ-LP40*5 | 0.543 | 6 | 75 |

| Flat Aluminum | BL50*5 | 6082-T6 | YH-HZ-LP50*5 | 0.679 | 6 | 412 |

| Flat Aluminum | LP130*5 | 6082-T6 | LP130*5 | 1.768 | 9 | 0 |

| Flat Aluminum | LP50*6 | 6082-T6 | YH-HZ-LP50*6 | 0.815 | 6 | 269 |

| Flat Aluminum | LP60*6 | 6082-T6 | YH-LP60*6 | 0.98 | 6 | 426 |

| Flat Aluminum | LP80*6 | 6082-T6 | YH-HZ-LP80*6 | 1.306 | 6 | 364 |

| Flat Aluminum | LP100*6 | 6082-T6 | YH-LP100*6 | 1.632 | 6 | 49 |

| Flat Aluminum | LP80*8 | 6082-T6 | HZ-LP80*8 | 1.741 | 6 | 304 |

| Flat Aluminum | LP120*8 | 6082-T6 | YH-HZ-LP120*8 | 2.611 | 6 | 150 |

| Flat Aluminum | LP120*8 | 6082-T6 | YH-HZ-LP120*8 | 2.611 | 3 | 5 |

| Flat Aluminum | LP150*8 | 6082-T6 | YH-HZ-LP150*8 | 3.263 | 6 | 44 |

| Flat Aluminum | LP180*8 | 6082-T6 | LP180*8 | 3.917 | 9 | 6 |

| Flat Aluminum | LP75*10 | 6082-T6 | YH-HZ-LP75*10 | 2.039 | 6 | 162 |

| Flat Aluminum | LP100*10 | 6082-T6 | LP100*10 | 2.72 | 6 | 52.5 |

| Flat Aluminum | LP215*10 | 6082-T6 | YH-HZ-LP215*10 | 5.848 | 6 | 52 |

| Flat Aluminum | LP250*10 | 6082-T6 | LP250*10 | 6.8 | 6 | 30 |

| Flat Aluminum | LP130*12 | 6082-T6 | LP130*12 | 4.244 | 6 | 42 |

| Flat Aluminum | LP150*14 | 6082-T6 | LP150*14 | 5.712 | 6 | 58 |

| Flat Aluminum | BL132*15 | 6082-T6 | 132*15 | 5.385 | 6 | 48.5 |

| Flat Aluminum | BL125*20 | 6082-T6 | YH6003 | 6.8 | 6 | 47 |

Typical Marine Grade Flat Aluminum Chemical Composition

| Alloy Grade | Silicon (Si) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Chromium (Cr) | Zinc (Zn) | Titanium (Ti) | Other Elements | Aluminum (Al) |

| 5083 | 0.40 | 0.40 | 0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.15 | Balance |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | 0.15 | 0.15 | Balance |

| 6061 | 0.40-0.80 | 0.70 | 0.15-0.40 | 0.15 | 0.80-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.15 | Balance |

| 6082 | 0.70-1.30 | 0.50 | 0.10 | 0.40-1.0 | 0.60-1.2 | 0.25 | 0.20 | 0.10 | 0.15 | Balance |

| 5454 | 0.25 | 0.40 | 0.10 | 0.50-1.0 | 2.4-3.0 | 0.05-0.20 | 0.25 | 0.20 | 0.15 | Balance |

Marine aluminum products you may be interested in

-

Marine-grade angular aluminum is used for reinforcing edges, frames, and supports in marine structures with L-shaped or angled aluminum profiles. It is valued for its structural support and corrosion-resistant properties.

-

Marine Grade T-Type Aluminum Profiles

Marine T aluminum is a type of aluminum profile specifically designed for shipbuilding, primarily used for connecting or reinforcing hull parts at a vertical angle.

-

Marine Grade I-Type Aluminum Profiles

Marine-grade I-beam aluminum: An I-beam or H-beam aluminum profile used in marine applications requiring high strength, typically used in the construction of beams, joists, and structural supports.

-

Marine Grade Aluminum Square Tube

Marine Grade Square Tube: A type of hollow square aluminum profile used in frameworks, railings, and other structural applications where both strength and corrosion resistance are critical.

-

Marine-grade aluminum troughs: A U-shaped or channel profile used in drainage systems, cable management, and structural components in marine environments. They help guide or support materials while resisting corrosion.

-

Marine Grade Aluminum Bulb Flat extrusions

The advantages of Aluminum Bulb Flat Extrusions over other types of extrusions are significant. Compared to traditional extrusions such as angles or flats, bulb flats offer better performance in load distribution and structural reinforcement.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.

-

As a professional aluminum manufacturer, we offer 6082 aluminum alloy flat bars that comply with ASTM B221/B211 standards. We support sea freight and offer bulk purchase discounts.