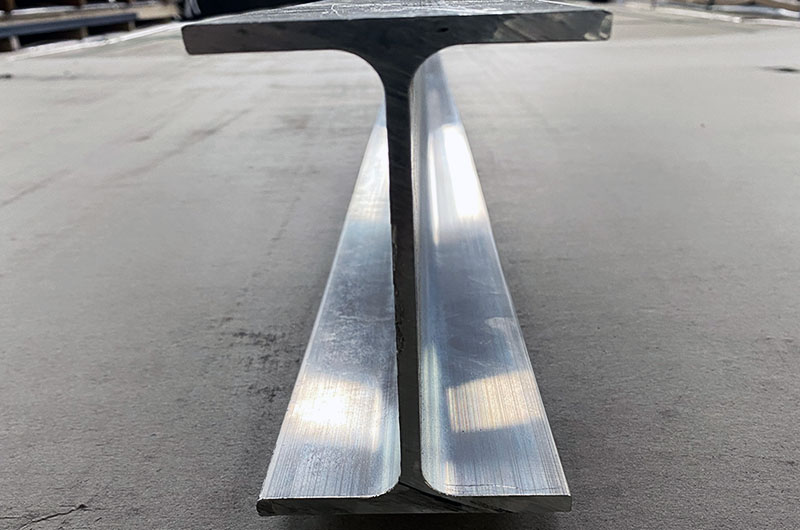

Marine Grade I-Type Aluminum Profiles

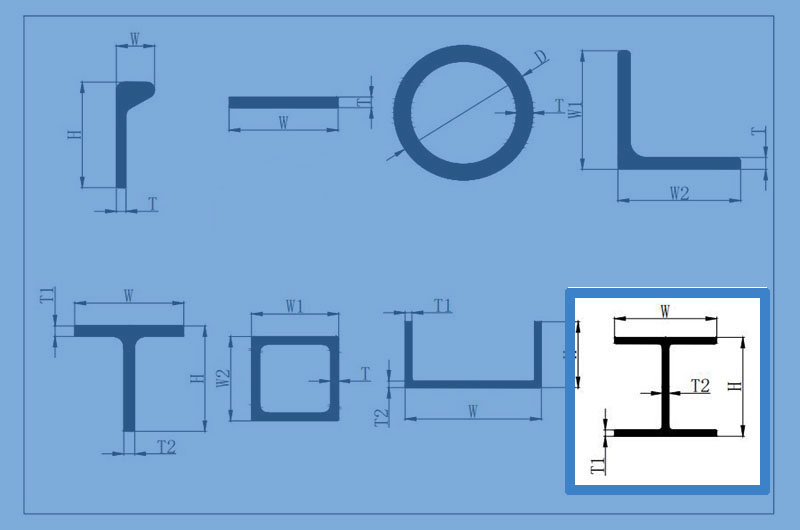

Marine Grade I-Type Aluminum: A type of I-beam or H-beam aluminum profile used in marine applications that require high strength, typically for the construction of beams, joists, and structural supports.

Marine Grade I-Type Aluminum has a cross-section resembling the letter "I, " which provides good stability and strength when bearing vertical loads.

Material Properties of Marine Grade I-Type Aluminum Profiles

- Corrosion Resistance: Special treatment or alloying gives it excellent resistance to seawater corrosion, making it suitable for use in salt spray and humid environments.

- Strength: I-Type aluminum profiles have a high strength-to-weight ratio, allowing them to withstand significant loads without significantly increasing the structure's weight.

Specifications of Haomei Marine Grade I-Type Aluminum Profiles

Marine Grade I Aluminum Specification Measurement

| Height (H) mm | 125 | 80 | 100 | 76.2 | 50 | 120 | 140 | 270 | 280 |

| Width (W) mm | 125 | 80 | 100 | 76.2 | 50 | 120 | 140 | 150 | 100 |

| Thickness 1 (T1) mm | 6 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 |

| Thickness 2 (T2) mm | 6 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 |

Marine Grade I-Type Aluminum Alloy Selection

Marine Grade I-Type Aluminum profiles typically use aluminum alloys such as 6061 and 6082. These alloys offer excellent corrosion resistance and mechanical strength, making them suitable for extreme conditions in marine environments.

- 6061 Aluminum Alloy: Offers good mechanical properties and workability, suitable for structural components that require high strength and flexibility in processing, ideal for various marine engineering applications.

- 6082 Aluminum Alloy: Provides high strength and good workability, ideal for marine engineering projects that require heavy load-bearing, making it an excellent choice for high-strength applications.

6061 Marine Grade I-Type Aluminum

- Strength: 6061 aluminum alloy has excellent mechanical strength, commonly used in temper T6.

- Corrosion Resistance: While slightly less corrosion-resistant compared to 5083, 6061 can effectively improve corrosion resistance with appropriate surface treatments such as anodizing.

- Applications: 6061 Marine Grade I-Type Aluminum is commonly used in marine engineering for structural frameworks, supports, and other applications requiring good mechanical properties and workability. It is suitable for use in situations requiring high strength and good workability, such as offshore wind power foundations and superstructures of ships.

6082 Marine Grade I-Type Aluminum

- Strength: 6082 aluminum alloy is one of the stronger aluminum alloys, commonly used in temper T6, comparable to 6061 but can be stronger in some cases.

- Corrosion Resistance: Although not as corrosion-resistant as 5083, 6082 can meet most marine application requirements with proper surface treatment.

- Applications: 6082 Marine Grade I-Type Aluminum is commonly used in marine engineering and structural projects that require high strength, such as hull structures, bridges, platform frameworks, and support brackets. It is suitable for heavy load-bearing applications, such as key components of heavy machinery and marine facilities.

Advantages of Marine Grade I-Type Aluminum

- 1. Lightweight: Compared to steel, aluminum is lighter, helping to reduce overall structural weight and increase load capacity.

- 2. Durability: Excellent corrosion resistance ensures longer service life in harsh marine environments.

- 3. High Strength: The design enhances strength, making it perform well under heavy loads.

Applications of Marine Grade I-Type Aluminum

- Beams and Joists: Used to support beams and joists in hulls, dock structures, bridges, and other marine structures.

- Structural Supports: Used as main structural supports in ships, platforms, and marine engineering.

- Marine Facilities: Widely used in offshore drilling platforms, port facilities, pontoons, offshore wind power foundations, and other engineering projects.

- Custom Structures: Used for custom marine structure components that require precise angles and strength, such as railings and brackets.

Processing and Welding of I-Type Aluminum

- Cutting and Welding: Marine Grade I-Type Aluminum can be processed through cutting and welding to meet specific structural requirements.

- Surface Treatment: Usually anodized to further enhance its corrosion resistance and surface durability.

Marine Grade I-Type Aluminum plays a crucial role in marine engineering due to its outstanding performance and adaptability. Whether used for structural support or as custom components, its high strength, corrosion resistance, and lightweight characteristics make it an ideal choice.

Typical Marine Grade I-Type Aluminum Profiles Chemical Composition

| Element | 6061 Aluminum Alloy | 6082 Aluminum Alloy |

| Aluminum (Al) | Remainder | Remainder |

| Silicon (Si) | 0.4-0.8% | 0.7-1.3% |

| Magnesium (Mg) | 0.8-1.2% | 0.6-1.2% |

| Copper (Cu) | 0.15-0.4% | ≤0.1% |

| Manganese (Mn) | ≤0.15% | 0.4-0.7% |

| Chromium (Cr) | 0.04-0.35% | ≤0.25% |

| Zinc (Zn) | ≤0.25% | ≤0.2% |

| Titanium (Ti) | ≤0.15% | ≤0.1% |

| Other Elements | Total ≤0.15% | Total ≤0.15% |

Haomei Marine Grade I-Type Aluminum Profiles Inventory

| Product Name | Specifications (mm) | Brand | Mold No. | Weight per meter (kg/m) | Fixed length(m) | Previous period inventory |

| I-Type Aluminum Profiles | I 90*50*4/10 | 6082-T6 | YH-HZ-I 90*50*4/10 | 3.535 | 6 | 28 |

| I-Type Aluminum Profiles | I 101.6*76.2*6.4*7.9 | 6082-T6 | YH-HZ-I 101.6*76.2*6.4*7.9 | 4.851 | 6 | 65 |

| I-Type Aluminum Profiles | I 108*40*4 | 6082-T6 | YH-HZ-I 108*40*4 | 2.005 | 6 | 35 |

| I-Type Aluminum Profiles | I 110*4-50*10 | 6082-T6 | YH-HZ-I 110*4-50*10 | 3.755 | 6 | 59 |

| I-Type Aluminum Profiles | I 120*60*5/6 | 6082-T6 | YH-HZ-I 120*60*5/6 | 3.463 | 6 | 34 |

| I-Type Aluminum Profiles | I 125*8/125*8 | 6082-T6 | I125*125*8/8 | 7.8 | 6 | 61 |

| I-Type Aluminum Profiles | I 130*5/80*6 | 6082-T6 | I130*5/80*6 | 4.445 | 6 | 27 |

| I-Type Aluminum Profiles | I 140*4-80*6 | 6082-T6 | YH-HZ-I 140*4-80*6 | 4.059 | 6 | 38 |

| I-Type Aluminum Profiles | I 152.4*6.35-76.2*10 | 6082-T6 | YH-HZ-I 152.4*6.35-76.2*10 | 6.57 | 6 | 10 |

| I-Type Aluminum Profiles | I 176*80*5/8 | 6082-T6 | HZAL-10 | 5.716 | 6 | 31 |

| I-Type Aluminum Profiles | I 182*60*4/6 | 6082-T6 | YH-HZ-I 182*60*4/6 | 3.854 | 6 | 0 |

| I-Type Aluminum Profiles | I 185*60*4 | 6082-T6 | YH-HZ-I 185*60*4 | 3.268 | 6 | 0 |

| I-Type Aluminum Profiles | I 202*60*4/6 | 6082-T6 | YH-HZ-I 202*60*4/6 | 4.105 | 6 | 0 |

| I-Type Aluminum Profiles | I 256*80*5/8 | 6082-T6 | YH-HZ-I 256*80*5/8 | 6.829 | 6 | 0 |

| I-Type Aluminum Profiles | I 270*6/100*10 | 6082-T6 | HZAL-25 | 9.578 | 6 | 24 |

Marine aluminum products you may be interested in

-

Marine Grade Flat Aluminum refers to flat, rectangular marine aluminum sheets or strips used in structural components, decks, and other flat surfaces on vessels.

-

Marine-grade angular aluminum is used for reinforcing edges, frames, and supports in marine structures with L-shaped or angled aluminum profiles. It is valued for its structural support and corrosion-resistant properties.

-

Marine Grade T-Type Aluminum Profiles

Marine T aluminum is a type of aluminum profile specifically designed for shipbuilding, primarily used for connecting or reinforcing hull parts at a vertical angle.

-

Marine Grade Aluminum Square Tube

Marine Grade Square Tube: A type of hollow square aluminum profile used in frameworks, railings, and other structural applications where both strength and corrosion resistance are critical.

-

Marine-grade aluminum troughs: A U-shaped or channel profile used in drainage systems, cable management, and structural components in marine environments. They help guide or support materials while resisting corrosion.

-

Marine Grade Aluminum Bulb Flat extrusions

The advantages of Aluminum Bulb Flat Extrusions over other types of extrusions are significant. Compared to traditional extrusions such as angles or flats, bulb flats offer better performance in load distribution and structural reinforcement.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.

-

As a professional aluminum manufacturer, we offer 6082 aluminum alloy flat bars that comply with ASTM B221/B211 standards. We support sea freight and offer bulk purchase discounts.