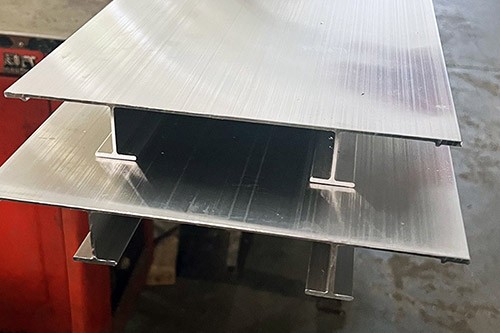

Marine grade multi ribbed stiffener aluminum plate sheet

Marine grade multi ribbed stiffener aluminum plate is a type of aluminum alloy material specifically designed for shipbuilding. Its main feature is the addition of multiple rib stiffeners on the surface of the aluminum plate to enhance its strength and stiffness. This aluminum plate is widely used in the hull, deck, and cabin structures of ships, providing excellent corrosion resistance and lightweight characteristics.

- The surface of the multi-rib stiffener plate is equipped with multiple rib strips, usually arranged at uniform intervals, enhancing the overall structural strength and rigidity.

- This design effectively disperses loads and reduces concentrated stress.

Marine Grade Multi Ribbed Stiffener Aluminum Plate Material

Aluminum Alloy: Typically made from high-strength aluminum alloys such as 5083 and 6061, which possess good corrosion resistance and weldability.

Advantages of Marine Grade Multi Ribbed Stiffener Aluminum Plate

- Provides maximum strength and rigidity, suitable for use in extreme conditions.

- The rib strip design significantly improves fatigue resistance, extending the service life.

Marine Grade Multi Ribbed Stiffener Aluminum Plate Features

- 1. Lightweight: The aluminum alloy material itself has a low density, which effectively reduces the weight of the vessel compared to steel, improving fuel efficiency and speed.

- 2. High Strength: The design of the multi-rib stiffeners significantly enhances the aluminum plate's resistance to bending and twisting, making it suitable for withstanding substantial external pressure and impact.

- 3. Excellent Corrosion Resistance: The naturally formed oxide film on aluminum effectively resists corrosion from seawater and other harsh environments, prolonging its service life.

- 4. Easy Machinability: Aluminum alloy materials have good processing performance and can be further processed through cutting and welding to meet different design requirements.

- 5. Thermal Conductivity: Aluminum has good thermal conductivity, which aids in heat management in high-temperature environments.

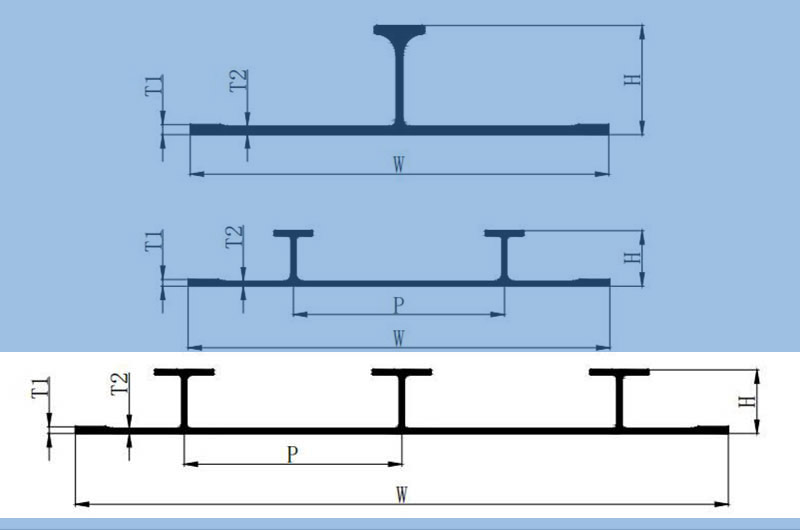

Marine Grade Multi Ribbed Stiffener Aluminum Plate Structure Design

- Multi-Rib Design: The design of the multi-rib stiffeners enhances the aluminum plate's resistance to bending and twisting, making it less prone to deformation under external forces.

- Optimized Shape: The shape and spacing of the ribs have been optimized to evenly distribute stress and improve overall stability.

Marine Grade Multi Ribbed Stiffener Aluminum Plate Applications

- Hull Structure: Used in manufacturing the outer shell and internal framework of ships, providing necessary strength and stability.

- Deck and Cabin: Used for deck laying and cabin partitioning, ensuring safety and comfort.

- Marine Engineering: Widely used in platforms, buoys, and other marine engineering equipment to withstand the impacts of waves and wind.

Marine Grade Multi Ribbed Stiffener Aluminum Plate Manufacturing Process

- Extrusion Molding: Aluminum alloy is shaped through an extrusion process, ensuring dimensional accuracy and surface smoothness.

- Welding: High-quality welding techniques are used to ensure strong connections that are resistant to cracking.

- Surface Treatment: Common surface treatments include anodizing and spraying, which enhance corrosion resistance and aesthetics.

Haomei marine grade multi ribbed stiffener aluminum plate sheet stock sizes

| Multi stiffened panel | |||||

| T1 | T2 | W | H | P | L |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 3.5 | 2.5 | 345 | 37.5 | 115 | 12500 |

Marine aluminum products you may be interested in

-

Marine grade single ribbed stiffener aluminum plate sheet

Marine grade single ribbed stiffener aluminum plate is a specially designed aluminum alloy material for shipbuilding, featuring a single rib structure to enhance its strength and rigidity.

-

Marine grade double ribbed stiffener aluminum plate sheet

Marine double-rib aluminum plates provide stronger structural support than single-rib aluminum plates and are suitable for high-load applications.